- 207

- 85 146 463

CNC Kitchen

Germany

Registrace 27. 12. 2016

Hi, I'm Stefan and I create educating and entertaining videos for you which feature 3D printing, CNC, CAD, Lasers, Arduino and much more tec stuff!

🏆 Do you want to help me cover my running costs? Send me a dollar or two over PayPal.

www.paypal.me/CNCKitchen

🌼 Even watching the ads before my videos helps me a lot!

🚚 Want to send me something? Please contact me via E-Mail first.

So sit back and enjoy more interesting stuff!

🏆 Do you want to help me cover my running costs? Send me a dollar or two over PayPal.

www.paypal.me/CNCKitchen

🌼 Even watching the ads before my videos helps me a lot!

🚚 Want to send me something? Please contact me via E-Mail first.

So sit back and enjoy more interesting stuff!

3D Prints Outside for 7 years: What happened? RMRRF2024

🚀Head to squarespace.com/CNCKITCHEN to save 10% off your first purchase of a website or domain using code CNCKITCHEN.

I recently visited the Rocky Mountain RepRap Festival 2024 in Loveland, CO to show you some really interesting and new stuff. Let's talk about a new Swiss Quick-Change Hotend, beautifully 3D printed images with HueForge and 3D prints that were left outside for 7 years!

Check out our *CNC Kitchen products* at cnckitchen.store/ or at our global resellers www.cnckitchen.com/reseller

Swiss3Dc Quick Change Hotend: www.swiss3dc.com/

E3D High-Flow Patent: patentscope.wipo.int/search/en/detail.jsf?docId=WO2021205174

HueForge: shop.thehueforge.com/

3D-PT (3D Prints Outside for 7 years): czcams.com/video/RSl2Q-ov4jI/video.html

Full Report: www.teacherspayteachers.com/Product/7-Years-Later-How-Does-3D-Printing-Filament-Last-Outdoors-10774491

💚 Support me 🙏

Patreon: www.patreon.com/cnckitchen

Join as a CZcams member!

Shop at Matterhackers(US): www.matterhackers.com/?aff=7479

Buy a Bambu Lab printer 🐼: geni.us/BambuP1S

Buy a Prusa printer: geni.us/CNCKPrusa

Shop at SliceEngineering: www.sliceengineering.com?p=rJPWEcsm_

Shop at 3DJake(EU): geni.us/zHvnB

PayPal: www.paypal.me/CNCKitchen

🎙Check out my Podcast with Thomas Sanladerer: czcams.com/channels/zUgJrG-w_KQexroYkJR9XQ.html

Follow me on Twitter: cnc_kitchen

Follow me on Instagram: cnckitchenyt

*Chapters*

00:00 Introduction

01:40 Swiss3Dc Quick Change Hotend

06:00 New High Flow Nozzle

07:54 Sponsor

09:17 How HueForge works

24:06 3D Prints left outside for 7 years

28:56 Outro

#3Dprinting #RMRRF #diy

DISCLAIMER: Part of this video was sponsored by Squarespace.

FTC Disclaimer: A percentage of sales is made through Affiliate links

I recently visited the Rocky Mountain RepRap Festival 2024 in Loveland, CO to show you some really interesting and new stuff. Let's talk about a new Swiss Quick-Change Hotend, beautifully 3D printed images with HueForge and 3D prints that were left outside for 7 years!

Check out our *CNC Kitchen products* at cnckitchen.store/ or at our global resellers www.cnckitchen.com/reseller

Swiss3Dc Quick Change Hotend: www.swiss3dc.com/

E3D High-Flow Patent: patentscope.wipo.int/search/en/detail.jsf?docId=WO2021205174

HueForge: shop.thehueforge.com/

3D-PT (3D Prints Outside for 7 years): czcams.com/video/RSl2Q-ov4jI/video.html

Full Report: www.teacherspayteachers.com/Product/7-Years-Later-How-Does-3D-Printing-Filament-Last-Outdoors-10774491

💚 Support me 🙏

Patreon: www.patreon.com/cnckitchen

Join as a CZcams member!

Shop at Matterhackers(US): www.matterhackers.com/?aff=7479

Buy a Bambu Lab printer 🐼: geni.us/BambuP1S

Buy a Prusa printer: geni.us/CNCKPrusa

Shop at SliceEngineering: www.sliceengineering.com?p=rJPWEcsm_

Shop at 3DJake(EU): geni.us/zHvnB

PayPal: www.paypal.me/CNCKitchen

🎙Check out my Podcast with Thomas Sanladerer: czcams.com/channels/zUgJrG-w_KQexroYkJR9XQ.html

Follow me on Twitter: cnc_kitchen

Follow me on Instagram: cnckitchenyt

*Chapters*

00:00 Introduction

01:40 Swiss3Dc Quick Change Hotend

06:00 New High Flow Nozzle

07:54 Sponsor

09:17 How HueForge works

24:06 3D Prints left outside for 7 years

28:56 Outro

#3Dprinting #RMRRF #diy

DISCLAIMER: Part of this video was sponsored by Squarespace.

FTC Disclaimer: A percentage of sales is made through Affiliate links

zhlédnutí: 85 126

Video

I added TPU fibers to PLA to make it super tough!

zhlédnutí 401KPřed 21 dnem

🚀Head to squarespace.com/CNCKITCHEN to save 10% off your first purchase of a website or domain using code CNCKITCHEN. I wanted to find out if I could resize my old 3 mm filament into a modern 1.75 mm filament, which led me onto a journey of making custom multi-color filament with incredible details on the inside. This method also allowed me to create a sample of TPU-Core PLA filament that treme...

Can you 3D Print with Hot Glue?

zhlédnutí 848KPřed měsícem

At www.kiwico.com/cnc and code CNC, you'll get 50% off your first month of KiwiCo's monthly subscription! Everyone uses a hot glue gun to explain 3D printing, yet nobody sells hot melt glue filament for a real 3D printer! I wanted to change that and make the first hot melt glue filament, for the giggles but also to 3D print iron-on patches! Let's find out more! Check out our *CNC Kitchen produc...

Why does Nobody Cure their Resin 3D Prints like this? (40% more strength)

zhlédnutí 169KPřed 2 měsíci

Head to squarespace.com/CNCKITCHEN to save 10% off your first purchase of a website or domain using code CNCKITCHEN. Resin 3D prints don't need to be weak! I investigated an alternative curing technique involving elevated temperatures that increased the strength of my parts by over 40%! Let's find out more. Check out our *CNC Kitchen products* at cnckitchen.store/ or at our global resellers www...

Solid-State Dehumidifier: The Ultimate Filament Dry Box

zhlédnutí 307KPřed 2 měsíci

Head to squarespace.com/CNCKITCHEN to save 10% off your first purchase of a website or domain using code CNCKITCHEN. I got my hands on some fancy solid-state dehumidifiers from the company Rohsal and tried to build the filament dry box of the future, which is maintenance-free and very efficient. Yet how does this novel technology compare to regular silica gel and how often should you replace th...

Brick Layers - Why did no one do this before?

zhlédnutí 987KPřed 2 měsíci

Brilliant is the best way to learn math & science topics! Go to brilliant.org/CNCKitchen for a 30-day free trial & the first 200 people will get 20% off their annual subscription. 3D prints still suffer from bad layer adhesion due to their 2.5D slicing and printing approach. I investigated if a novel slicing method that interleaves the layer could improve the strength of 3D prints. Check out ou...

Calibration Cubes: More Harm Than Good?

zhlédnutí 332KPřed 3 měsíci

Head to squarespace.com/CNCKITCHEN to save 10% off your first purchase of a website or domain using code CNCKITCHEN. Too many people seem to calibrate their 3D printers with calibration cubes. I think this is a bad idea. In this video, I’ll show why calibration cubes are bad, how you properly tune your printer's dimensions, and how accurate the machines I have in my studio are! Vector3D CaliFlo...

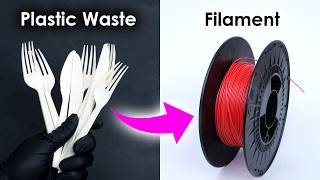

From Trash to Treasure: Recycle Cutlery into 3D Filament!

zhlédnutí 178KPřed 4 měsíci

Brilliant is the best way to learn math & science topics! Go to brilliant.org/CNCKitchen for a 30-day free trial & the first 200 people will get 20% off their annual subscription. Single-use Plastic Cutlery is not only horrible to use but also produces a lot of waste. I tried recycling it to 3D printing filament and documented my journey. Let's find out more! Check out our *CNC Kitchen products...

Bambu Lab A1 Review: Game-Changer or Hype?

zhlédnutí 397KPřed 4 měsíci

Bambu Lab just released their new 3D printer, which (unfortunately) is another bed slinger. The A1 is a bigger version of the A1 Mini with the same build volume as the P1 and X1 printers. Yet, how good is it and how does it compare to the more expensive CoreXY machines? Check out our *CNC Kitchen products* at cnckitchen.store/ or at resellers www.cnckitchen.com/reseller and on AMAZON (EU) geni....

Recycling Failed 3D Prints with a DIY Filament Extruder: Artme3D

zhlédnutí 1,4MPřed 5 měsíci

At www.kiwico.com/cnc and code CNC you'll get 50% off your first month of KiwiCo! Everyone complained that I always use multi-thousand dollar equipment for my recycling project, yet I finally found a very promising Germany DIY filament extruder! Let's build and try out the DIY Artme3D filament extruder kit and recycle some old 3D prints with it! Check out the Limited Edition Soldering Iron Tip ...

14 3D Printing Innovations in 18 minutes: Formnext 2023

zhlédnutí 333KPřed 5 měsíci

Visit the CNC Kitchen shop: cnckitchen.store Free shipping in Germany (faster than Amazon) & worldwide free shipping for orders €100 and more! ELEGOO OrangeStorm Giga: www.kickstarter.com/projects/elegooofficial/elegoo-orangestorm-giga-gigantic-volume-fast-fdm-3d-printer phrozen ARCO: phrozen3d.com/ Bambu Lab: geni.us/BambulabX1 Prusa Research: geni.us/CNCKPrusa Duet3D: www.duet3d.com/ E3D Onli...

High Temperature & 5-Axis Printing: Vision Miner 22 IDEX V2 at Formnext 2023

zhlédnutí 111KPřed 5 měsíci

Thanks to Vision Miner for helping me get to Formnext 2023. Check out their 22 IDEX V2: visionminer.com/products/22IDEX and get 10% off their Nano Polymer Adhesive with code CNCKITCHEN : geni.us/NanoPolymerAdhesive I had a great time talking to Rob and Nazar about the 22 IDEX V2 by Vision Miner. They gave me some really interesting insight into what challenges there are with high temp printers,...

MINGDA's giant 1000x1000x1000 mm 3D Printer at Formnext 2023 #AD

zhlédnutí 62KPřed 6 měsíci

Thanks to MINGDA for making my trip to Formnext possible! Check their professional offerings at www.3dmingda.com/ and their consumer printers at 3dmingdaofficial.com/ Most of you will know MINGDA's Magician Series of 3D printers, but did you know that they are also making large volume industrial printers? They not only showed their MD-1000D, MD-600D and MD-400D at Formnext 2023 but also present...

Turning 3D Print Waste into New Filament!

zhlédnutí 1,3MPřed 6 měsíci

I tried to make new filament from the multi-color purging poop of my Bambu Lab printers, and it wasn't straightforward. Let's find out more! Check out our *CNC Kitchen products* at cnckitchen.store/ or at our global resellers www.cnckitchen.com/reseller Visit voxelpla.com to get their reliable yet affordable filament for only $16.99 a spool & the all new BENTO BOX 2 Air Filter! Get a Bambu Lab ...

Heated Chambers: Game-Changer for 3D Prints?

zhlédnutí 178KPřed 6 měsíci

Thanks to QIDI for sponsoring this video. Check out the QIDI X-Max 3 here geni.us/QIDI3D and get a special discount with code CNCKITCHEN30 It is common knowledge that higher technical materials should be printed in a heated chamber. But why do they warp less when printed in a warm environment, and how much stronger do they get? I used the QIDI X-Max 3 with its actively heated chamber to test ex...

Bambu Lab's NEW A1 Mini and why they didn't release an X1 XL!

zhlédnutí 284KPřed 7 měsíci

Bambu Lab's NEW A1 Mini and why they didn't release an X1 XL!

PET Bottle Recycling: Waste to 3D Printing Filament

zhlédnutí 758KPřed 7 měsíci

PET Bottle Recycling: Waste to 3D Printing Filament

Egg Drop Revolution: The Smartest Egg Ever!

zhlédnutí 272KPřed 10 měsíci

Egg Drop Revolution: The Smartest Egg Ever!

3D Printing Resistors, Fibers & Coffee - Utility Research Lab

zhlédnutí 85KPřed 10 měsíci

3D Printing Resistors, Fibers & Coffee - Utility Research Lab

3D Printed, DIY "Interlocking Bricks": PrintABlok

zhlédnutí 89KPřed 11 měsíci

3D Printed, DIY "Interlocking Bricks": PrintABlok

E3D made an impressive HIGH FLOW nozzle!

zhlédnutí 220KPřed 11 měsíci

E3D made an impressive HIGH FLOW nozzle!

10 AMAZING 3D Printing Projects: Rocky Mountain RepRap Festival 2023

zhlédnutí 148KPřed 11 měsíci

10 AMAZING 3D Printing Projects: Rocky Mountain RepRap Festival 2023

Should you buy a NEW Prusa MK4 in 2023 or rather a Bambu Lab X1/P1P?

zhlédnutí 818KPřed rokem

Should you buy a NEW Prusa MK4 in 2023 or rather a Bambu Lab X1/P1P?

Fast 3D printing is bad for Strength! (and how to fix it!)

zhlédnutí 347KPřed rokem

Fast 3D printing is bad for Strength! (and how to fix it!)

Revolutionary Arc Overhangs are now in PrusaSlicer*

zhlédnutí 278KPřed rokem

Revolutionary Arc Overhangs are now in PrusaSlicer*

Glow in the Dark Filament for 3D Printing

zhlédnutí 150KPřed rokem

Glow in the Dark Filament for 3D Printing

I tried to find the Strongest Filament Extruder.

zhlédnutí 379KPřed rokem

I tried to find the Strongest Filament Extruder.

Myth Busting: Color vs Strength in PLA

zhlédnutí 131KPřed rokem

Myth Busting: Color vs Strength in PLA

Is it possible to do some accelerated environmental testing? Maybe a high humidity chamber with changing temperature with a strong UV light? The major problem with tests like that is time and we lack many good experiments to do with environmental conditions so most people are just left to choose a filament that might work well but they never really know until they test it. His test results are interesting but it would have been good to see some more ABS and some ASA. I would also have been good to see some other types of test, like burying the print, putting it in a pond, etc.

I WANT THAT QUICK CHANGE HOT END!

Selling information. Booooooooooooooooooooooooooooooooooooooooooooooooooooooooooooo.

For me it is the Best filament for Technik parts. I have printed anny spare parts with this filament. Layer adhesion is very high.

Thanks for your review. Have a MK3s and going to replace with an MK4

How does line width over 100% affect dimensional accuracy?

hi, two years later how it works?

Wish I could have been there. Thanks for sharing 👍🏼

I noticed you there but you were always heading to something and I didn't want to bother you. So glad you came.

That photolithophane stuff looks REALLY COOL. That might actually be fun to play with once I (eventually) get my 3D printer set up and running

What I’d like to see in a hot end is a deflector that guides the filament away from the extruder in the event of blob. Also make a hot end filament will not stick to and run the wires inside a tube or housing where they are protected where blobs can’t destroy them.

I recently watched some of your print test videos and got to a question. Could you print a shell part with a 2mm hole on top, which you then fill with some type of glue/epoxy resin? After it has hardend, you should have prettymuch perfect strength uniformity and form stability at minimal filament use and time investment. (if the fuid pressure becomes large enough to deform the vase mode print could one do it via a number of layers or shells (like chocolate easer bunnies)) Would be interested to see some numbers on that.

I compared two benchies one in PLA and the other in PETG both Aurarum filament in orange and over the three years the PETG only lost colour, the PLA went brittle and faded within a year. A longer experiment would be interesting, Go for it Stephan.

Where do you get the color detection thing the hueforge guy is holding

Wow that quick change nozzle from swiss looks perfect!

Great video about those hotends and Hueforge... Who is that dude with that red hoodie and white letters on the back, was he stalking you?

Really want to see the alumina vs silica graphs that were briefly shown in a previous video! The slide was taken down from the video... hope to see it in the next video!

Heck yea flying gantry 😎

I need that bambu lab upgrade. I installed the bambu lab hotend on my Ender 3 and it's absolutely lovely. This would make it even better.

no ASA? tsk tsk

guys i cant afford 60 usd can someone hook me up with the file

If only there were some accurate way to print colour images already

I used PLA for my turn signal button of my mortocicle. It is parking part time in a garage and part time outside in germany. It it 2,5 years so far and no proplems at all with color degradation (black pla) or becomming soft in the sommer. I think it was geeetech PLA.

I'm a noob to this great info

I agree. The Bambu is the clear winner.

Sheersh I didn’t know this was happening here! I live like 5 minutes away

Next year! 💪

I thought for the software folks. Slicers that are able to vary the Z axis as they print a layer are about to become a thing. This will allow curved shapes of the colored layers in a print. Thus you likely can make images with better 3D

PLA outside - 4 years ago I designed & printed a large NHS logo which has the Superman S, 20x7cm sized, 5 colours glued together, and bolted it to the wood fence of the substation along my road. It's still there in great condition probably because it doesn't get direct sunlight. I even found photos of it for sale on Alamy from two different people!

it seems like you should have tested how they would have held together under a bending force and not a stretching force.

don't wanna rain of the Hueforge guy's parade, but 70$ A YEAR for the privilege to sell physical art you made using their tool as a fractional portion of the process with a lot of physical labor is downright insulting. The 3d printing space had been going down a very concerning path with land lording licenses for years, but this might just be the most out of touch one I've seen yet

So basically you’re doing what candy makers have done for over 100 years :P 😂

would be cool to see an automatic tool changer with the Swiss3Dc quick change hotend!

On the outside...can he pain them with clearcoat UV and color spraypaint? unprotected and then coated with clearcoat and color (think white for heat protection) but have UV protection built in... I highly recommend testing them...awesome! Keep em coming!!!!

Nice! Ein Tesla! Aber warum hast du denn das Kassengestell in "Stingy White"?

I tried HF one time and found it kinda pointless. It's basically 2D printing on a 3D printer. For me, I'd rather print the images out on a canvas and frame them. It produces no plastic waste and still looks the same. From a distance, you can't even tell the difference.

Interesting stuff ^^ Concerning prints left outside: I park my e-bike on our south-east facing balcony, and since I store the battery pack indoors I printed a cap for the power connector out of white TPU. It has seen the full range of south German weather for a bit over 1 1/2 years, and so far the only change I noticed is that it started to yellow and maybe get a bit stiffer on the parts that were exposed to sunlight. Other than that it's still holding up great.

Combine this method with superslicer of offsetting different extrusion widths on the outside perimeter. .8mm and .4mm widths if you have a .4 nozzle could potentially give you another increase in strength cause there's still a tower on the outside perimeters.

The correct term for the filament reshaping into a thinner element is necking: en.wikipedia.org/wiki/Necking_(engineering)

i'm now about half tempted to see if I still have the failed number I printed , and then go pull a number off the mailbox send them to you let you cut it open .. One a painted pla part vs unpainted in the house ?? they are even hollow because I was gonna use rgb lights in side the numbers but I found a faster cheaper option that came with solar panel and battery :) oh and this is a south Texas location last summer we had like 80 days over 100 degrees . Heat indexes 120 + degrees what that like 50c ?? wonder what shipping costs lol

i use my old matters

I like hueforge i just wish they didn't use ai art

7:50 It's disgusting that internal nozel patterns can be patented .

WOW HueForge is amazing

What a coincidence, I was just yesterday looking up how hueforge works

I've had PLA prints sitting in full sun, snow, whatever, year on year and they are fine. I made sure to print white so they reflect the sun. They are also printed thick walled. Look the same as when I first put them there.

10:20 Is that AI art? <:s

Probably^^

@@CNCKitchen Aw that sucks. :(

Uhhh... 3d printed car parts sounds like a very bad idea. With out current tech, this will not be durable nor safe.

That 7 year experiment is super cool. I would have loved to see some ASA samples but I guess that wasn't really a thing at the time...

the street number I printed for my package delivery box are 6" tall white pla I painted black and have been in direct sunlight for deco I think they will live but I bet that are getting brittle next couple years at least ?? or the paint really gonna make a difference to the overall deterioration

If you recreate that experiment, you should paint some samles. Check if paint can protect the platic from the enviroment