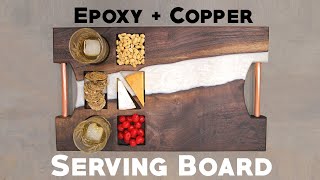

Epoxy Cutting Board DIY

Vložit

- čas přidán 24. 05. 2024

- In this Video we show you how to make an awesome river style cutting board from start to finish!

check out my friend over at Capturing Christianity: / @capturingchristianity

Hoodies and T-shirts: teespring.com/stores/goodview...

Epoxy: www.stonecoatcountertops.com/...

~~~~~~~~~~~~~~~~~~~~~~~

Tools and Materials(affiliate links):

~~~~~~~~~~~~~~~~~~~~~~~

Pearl Pigments: amzn.to/2Lofoay

Butcher Block Oil: amzn.to/2YbCTFl

Brush: amzn.to/2WqBg5Y

heat gun: amzn.to/2VfbuW1

Bandsaw: amzn.to/2VIc3qM

Drill: amzn.to/2VJ1bZr

Planer: amzn.to/2WqjtvN - Jak na to + styl

![[Vowel]물고기는 물에서 살아야 해🐟🤣Fish have to live in the water #funny](http://i.ytimg.com/vi/3G9MH063Cx4/mqdefault.jpg)

I had to re-watch this video after a year. It's the cid that got me hooked on Goodview, Nathan and resin crafting. Still lovin' it all.

Lost Sailor thanks bro!!! I appreciate that!

I’ve been having a hard time clamping my form to my table but I see how you raised it, that a great idea, thanks!

I’m in love with your cutting board!! It’s beautiful!!

Thank you!!!

I'm just a beginner and your video was the best I've watched thus far...awesome...thank you.

Great video! You make me feel like I can really do this myself with the steps you demonstrate. Thank you for taking the time and effort.

Appreciate the hard work! After watching several of your videos, this is, by far, the best music (to me)... Thanks for sharing!

Your last name is one letter away from mine

Oh I want one of those. I love your creations.

Thank you!!

You are absolutely brilliant! I love watching your videos, so informative and easy to follow, keep up the good work and especially THANKS for sharing! ❤️

I watched this whole video just to see it set up as a charcuterie board. I wanted to see the end product with food on it. Well on to the next vide! Great job! I love the finish product.

Your Videos helped me finish my first river table. Thank you. Your work is fantastic 👍.

Just found your channel and I subscribed, amazing work, great video's, positive vibes but the best part is you actually take time to answer people's questions!! Most people just post video's and never answer any questions!! After watching just a few of your video's I'm getting ready to try a few small practice projects!! Thanks for your time, you're a natural teacher!! You make it look so easy!!

Thank you so much. If you have any questions please don’t hesitate to ask.

Hey I took your advise and subbed. This is your first video that I've watch and i can tell that I'll like following your channel. The project was awesome, great job.

Thanks a lot!!

Great job at doing a step by step tutorial. Most videos just do it without explaining. This was very educational.

King Leo thanks! That’s one of our goals here on CZcams, to teach people. Thanks for watching!

Wow! Great job and great job at showing us how to do this! Thanks! Can't wait to make one!!

Thanks so much!!

Thank You for your fast reply!

You freaking help me so much. Your so simple not all these crazy tools I don’t have lol you the best!!

Nice job. I didn't know you could use clear packing tape for the mold. Thanks for the learning experience.

Thank you! You’re very welcome 😉

Looks amazing!

Thanks for the info and great looking project.👍🔨

No problem, thanks for watching!

what a great job. I will be making one now, Thanks and keep it up

Hey love your work .... thank you for your time....God bless you, your friend from Canada....

Thank you so much!!

Nooice!! Great job and I love the color!

thomas heroux 🤣 thanks bro!

my friend. very nice. thank you so much. be happy.. bravo

Thank you!

Dustright has a 5micron bag that fits your planer. It's less than $40 and works. Great videos, keep it up

Thanks! I’ll check them out!!

Great video. Iv been planning on doing something similar and your video is extremely helpful. Thank you from the U.K. 🇬🇧

Beautiful job Nathan

Nice work! Would love to see a break down of cost of materials and total working time on projects like this.

I'm going to try and get a wood shop up and running, ultimately I would love for these live edge projects to be my primary production. So it would be interesting to see the cost breakdown.

Thanks so much! It cost me about $37.50 to make this board.

@@GoodViewWoodworks how much do you charge for a piece like that? BTW excellent channel, love it, keep up the good work!!!

That looks awesome!

Hey Nathan! Love your works, you are so talented! Thanks so much for sharing your knowledge and experience. May I ask, what kind of epoxy resin do you use? Thanks..❤️

Wow, what a beautiful cutting board.Lots of work though. I'm jealous of all your cool toys :)

Do you get snipe on the end of your board when you run it through your dewalt planner.

GoodView Woodworks

Very Good !!!

Thank you!

@@GoodViewWoodworks Nothing, I have to learn a lot from your videos

I really like the translucency of the epoxy

Nice job Nathan. Now I need to find some live edge wood and try it. 😊

Beautiful job!!!

Hey thanks Jennifer!!

Wonderful gift from the heart 👍

Thanks Mike

Nicely done sir, enjoyed watching this video :)

Thanks D1

Awesome work !

Thank you!!

Best tutorial I've seen sooooo far. It is even better than the ones from the "big channels" thank you so much ☺️

i too use packing tape for my epoxy projects, i found the best success with the Duck brand tape, i get it in the 3" width online, i think their plastic film is thicker and easier to work with because it starts and tears cleanly, and the extra inch width of tape is nice.

Nice! I’ll check it out

Love that you give your friend a shout out on your video. Two things I'm always looking for -- a quality DIY channel, and a quality Christian apologetics channel. Got you both a sub.

That’s awesome man! Thanks!!

Am I really the only person that has modest concern about cutting into, then eating food from an epoxy cutting board?

There shouldn't be any such thing as an "epoxy cutting board," only "epoxy serving boards."

Yes...

That epoxy has a pull apart strength of 22 thousand pounds per Sq inch...you can hit that epoxy with a sledge hammer and it may chip...good luck cutting it with a knife ...will dull it first

I had the same question. Beautiful piece soon to be marred with a knife. But I was wondering about the food safe part of the epoxy. Read that cured epoxy was non-toxic. So why are some graded as food safe and others not? The video on making it was great. Will look for more of his utubes.

Epoxy when cured is a plastic cutting board totally safe

That was a really great tutorial, thanks 😁

Thank you!

I agree!!!

Great job and you’re a hoot

Question: how does the epoxy stand up to sharp kitchen knives? Thank you. Beautiful work!

RMG CBG great question! Sharp kitchen knives will score the surface. But you can always scuff and recondition the surface.

Great job as always Nathan good idea about putting holes in the sides do u think that would work on bigger things like tables maybe?

Nick Garza absolutely !!!

Wow, I love it

Looks great 😁! You are an amazing artist! Which resin do you use so it doesn't get damaged by cutting on the cuttingboard?

I like your tutorials...... you are good.

WELL DONE!!

Wow!

Awesome video.

This was a fantastic tutorial

Thank you!

Looks cool, I differently will do this, thanks.

Is the link to the materials working, I see the words, but no link?

Hey man Sorry I haven't replied!!! They should be up and going at this point. thanks for the heads up!!!

Great video..it really helped for when I made my cutting board. Quick question I did the same thing as you with the sanding and then oil. When you let it sit over night after it dried were you able to see any scratches in the epoxy? I can see some and I'm pretty bummed. What can I do to fix it?

Just need to make sure you sand thoroughly. Also you may want to go to a higher grit as well. Hope this helps.

Thanks for a great video! Im about to make my first board. Just wondering if i can use an electric hand planer, rather than the big automatic one you have?

Yes you can !!

The dowel holes are game changing

Great work! I ordered some Total Boat for another project my question is can I use that brand to try to do a cutting board like you did here?

Yes you can just make sure to get the total boat thick set epoxy

Another idea for Tuesday. How to guesstimate how much epoxy you need for a pour. I’m not Einstein so I have a hard time making the right judgment. Also your draw string at the beginning of the video was setting my OCD off like the 4th of July.

Great idea! Bro you are hilarious! 🤣😂

You just need a little multi-variable calculus.

Question, wouldn't the dowels be more efficient if the holes were drilled after the sealing epoxy? 🤔

Amazing end result, keep up the great work

Hey I posted on my channel a cutting board I made with 1200 color pencils and epoxy cool as hell. Thanks for your advice on Facebook

No problem bro!

good work👍

Thank you

Nice job ! That came out beautifully ! What is that scaley looking thing in the corner behind you on the right at the end of your video

Ty Taylor oh 😂 it was a wreath that my wife wanted to hang on our wall 🤣

Hi Nathan, really nice job! Gonna try it myself. I assume you've already given the board away, but I was wondering, just out of curiosity, what were the final dimensions (approximately)?

Thanks Russell! The dimensions were approximately 10”x 20”

What size did you make this? Great job and love the channel. Thank you

Thanks man!! It was 12x24

You do a great video and job!Have a couple of questions for you!

When you drill the hole and put the fine coat of epoxy on does enough get to go into the holes to make a difference ? I see in another video you did you say not to coat where the bark was. Were you talking about on all things or just the table you were working on? Does the epoxy hurt the knifes on a planer?

The holes is an older technique. I don’t do that anymore because I use a casting epoxy that takes a longer time to setup which in turn absorbs into the edges much deeper. This gives the strongest bond. I do this on all things now. The epoxy is a little harder on the blades but it’s barely noticeable.

Really nice!

Ok any dude who is so nice and has an awesome dog oh yes and the art is amazing I’m going to subscribe now 💫💫💫💫

😂 thanks Tracy!!!!

Nice one!

Looks brilliant! ! One question though, how will it stand to actually being used ? Unless your mom has got a huge kitchen, it really looks too big to just sit around looking really cool.

😂 it will get scratches from the blade. It will be the same as any wood cutting board. It’s really not very big. The finished size is 12x20

Nice video, I’ve got some leftover pieces of wood that I can use to make some of these

Thanks! You should!!

I started playing/working in my uncles cabinet shop when I was 9, but I never worked with epoxy till about two months ago and I’m hooked!!🤩😎

It’s a lot of fun, isn’t it!?

Great video and finished product! What setting on the heat gun did you use? Does it even matter?

I only have a low and high setting on my heat gun and I usually use the high setting. It doesn’t really matter that much. Having said that, if it’s not hot enough it will be hard to pop bubbles.

Question for you. I have watched a few of your videos working with wood and epoxy, like the 4 or 5 part coffee table build. I believe this is the first time I have seen you drill the hold on the inside of the boards so that the epoxy can act as dow rods. Why was it needed this time and not when you did the coffee table? How can I tell if my project I am working on is going to require me to do that? I am a complete beginner and looking to begin my first project soon. Thanks for the great videos!

Great question! The only reason you would need to do that is if you’re not going to encapsulate the entire piece. If you notice, in this video I didn’t pour a flood coat. Hope this helps!

How long did you let the epoxy cure for on the seal coat on live live edges before you did the main river pour?

does the heat trick only work on that epoxi or could you use it on others as well Im going to start making my own pen blanks and typically you put it in a vacuum chamber or pressure pot to get bubbles out

It works on most epoxies

Where did you get the slab of wood ? great job, plan on making a cutting board soon !

you use Different epoxy for different projects how do you determine what you're going to use? I'm looking to order but don't know which to order for my table

The countertop Epoxy is just to coat the surface and the casting resin is for thick pours. Thanks for asking!

I used fomwood apoxy for cutting board is it safe to cut on it ,chemical wise ,did not look into ,nice looking board u made ,thx in advance

Awesome job can it be used as actual cutting board ?

Any suggestions for how to level off a finished slab with no router or planer?

Take it to a place that has a CNC and have them flatten it...? I have done that in my other videos to give people more options.

River Table for Boat DIY Part 3 || Prepping for Finishing W/ Stone Coat Countertops Epoxy czcams.com/video/euweR2hgX8Q/video.html

Hey Nathan, when you run a piece through the thickness planer, do you plane all the way down to the wood?

Yes! You’re correct

Are you going to start doing the hole drilling thing with your big projects too? I’ve never seen you do it before.

Great question! If the live edge is super straight, i will.

Hi Nathan! It's been a little over a year since you made this cutting board, I remember watching it and think I wonder what it would look like after it's been used. I'd love to know have you used it, how often, and what does it look like now? I think it would make a cool CZcams video "Before & After" just a thought

Marco Velez hey brother that’s a great idea. The only problem is I sent it to a fellow CZcamsr several states away 😅. I’ll try and see if he has any pics.

Great videos is there a minimum thickness needed for these ?

Planning to make a

Bench as

Well ,same question minimum. Thickness ?

I would say no thinner than 3/4” and for a bench, no thinner than 1.5”

Love it man

New sub

+David Morgan thank you!!

You used a drill with a stirrer to mix the epoxy. How did you get the epoxy off the stirrer or do you just throw them away ? TIA

Richard Weiss great question! I just take a paper towel and wipe it off after i let it sit and drip for a few mins. I had this drill mixer for over a year and haven’t needed to replace it yet.

Hi fun stuff lovin it! I also live that you give your friend a plug BUT chiming in because you mentioned In another video we don't have to worry about the wipe because it just helps get a better surface to mix everytime. Do we need to clean it each time?

Nice project.

I'm just starting out using epoxy.

I got myself a beautiful piece of Manitoba cherry. Was 33x16 inch. Cut it to about 16 inches by 16 inches by 2 inch thick with live edge.

Natural oranges and reds flow through it. My plans are to make a reverse river. I'm prepping the wood, removing bark. I'm noticing a lot of small surface cracks between the grains.

My question is, how do you calculate the amount of epoxy needed?

I don't want to waste more than I have to.

If needed I'll post a quick video with the plans.

czcams.com/video/yB0zLPwDO9k/video.html

Check out this video. Hope it helps.

@@GoodViewWoodworks Perfect. Thank you for the link.

Side note,

Subscribed.

Keep up the awesome work.

Very good video. One question: what did you use to seal the frame?

I use silicone caulk

Hi, what or which polish did you use? What would you recommend for walnut board? Thx

What caulk did you use?

Great video btw. Thank you for sharing.

I use 100% silicone caulk

super good video!!

After you poured the blue center. Did you pour clear epoxy on top when it dries? Or is blue too.

All of the Epoxy I poured in this video is blue.

Hi! How did you treat the back? Did you sand it and add the oil to it as well or left it the way it came out of the cast?

Kathryn Pstrak great question! I sand and apply the butcher block conditioner the same way as the top!

Since you're doing multiply pours you don't have to color the bottom pour. Mineral oil from the drug store is cheaper than the butcher block oil. I just let the cutting board soak for 30 minutes or so in a mineral oil bath. Let it drain off until there is no standing oil than rub it dry. Mix up some melted bees wax and mineral oil in a 2:1 ratio. Apply the wax for a final coating on the cutting board. Tell the customer only hand wash and clean it with half a lemon and kosher salt once a month then rub it down with some mineral oil. I also tell the customer that I'll resurface the board once a year. That way you stay in touch with a customer. If they bought once, they'll buy again.

Thanks mike! I really appreciate that!!!

Actually you do need to color the bottom pour because you will see that layer on the end.

Awesome!!!

What is that final oil wax mixture you rubbed on and where to get it?

It’s butcher block conditioner. I have it linked in the description. You can get it at Home Depot as well

Hey I know this all about making $$$, how much would this piece go for? Looks like many hours and efforts which a lot of us do enjoy watching...keep it up!

Rory B hey thanks bro! I would say around $75

Great job!

What about cleaning that stuff with water after use, doesn’t it leave water marks?

After a wash or 2 you’ll need to apply more butcher block oil. After you repeat that more and more, less and less oil is needed. Eventually when the board is seasoned with oil you’ll only have to do it once a month if you’re using it regularly.

Looks nice, how much epoxy did you end up using for it?

Good question. I ended up using just under 1 quart.

Great job Nathan - quick question - I like the “epoxy dowel” idea but doesn’t it create more air bubbles sources, just as you precoat the live edges?

I had the same question. Also, this is the only one of his epoxy projects that I can recall seeing this "dowel" idea used. I'd like to know if that's because it causes problems or because it's just unnecessary.

It’s because it’s unnecessary. If you use the correct type of epoxy (slow setting casting epoxy) the dowels are not needed because the epoxy has time to soak into the edges creating the strongest bond.