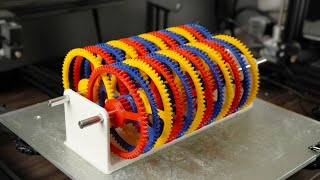

Fastest 3D Printed Gearbox Ever.

Vložit

- čas přidán 18. 06. 2023

- 1. Get $100 Off the Creality Ender 3 V2 3D Printer: micro.center/3wp

2. Get $80 Off the Creality Ender 3 S1 3D Printer: micro.center/58s

3. Shop Micro Center’s Inland Filament: micro.center/ztq

Redeem Exclusive Offers for Micro Center’s New Store in Indianapolis: micro.center/hdo

New to 3D Printing? Start Here:

3dprinteracademy.com/blogs/ba...

- NEW MICRO CENTER STORES: www.pcmag.com/news/electronic...

- NEW Indianapolis Micro Center - Opens Summer 2023!

- Micro Center Laptop Sales event: www.microcenter.com

Accelerate your 3D printing journey: www.kickstarter.com/projects/...

____

The world's most practical 3D print: Thread Boards

3dprinteracademy.com/products...

Website: 3dprinteracademy.com/

Unique High Quality STLs: 3dprinteracademy.com/collecti...

Learn: 3dprinteracademy.com/blogs/3d...

Online Courses: 3dprinteracademy.com/collecti...

350W DC Motor: amzn.to/3Py7U3U - Věda a technologie

Use bearings wtf

It’s a gear box not a bearing box

@@Fedsema124he means to use bearings on the gears

@@yobtnirp oh that makes more sense

@@yobtnirp sorry

You would get higher speeds just by lubricating the gears with a silicone spray. You could do a before and after run to see how large the improvement is.

He just did idiot, watch the whole video before you comment.

guy dunks oil all over the gears, no way they're under-lubed

@@poptartmcjelly7054 lube up 😏😏😏😏

@@poptartmcjelly7054 Too thick and viscous, needs something really light weight and not sticky.

Wd40

im not a engeneer or something like that but i think torque would be a problem

It is. Just an inevitability from the engines

Yes, but there is no load. Its like picking up nothing vs picking up a tv, you would run out of torque to pick up the tv but not the nothing because there is nothing to lift

@@jascow here there is something to "lift" though. Each gear acts as tension applied, creating the need for torque.

That’s what I was thinking lol

@@jascowbruh, you forgot friction inefficiency. Even without a load, if the gears have too much friction, the machine won't work.

Cool

But did you think of using bearings for gears ? You already use non printed axels

Bearings can significantly reduce friction between gears and axels, resulting in much higher resulting speed.

Also bearings will help with precision which will help to reduce friction between gears and will not let them wobble (this is frictions losses too)

And if you mad enough you can end up using ceramic bearing instead of usual ones, which do not need grease and have extremely low friction.

This will give you the best result, but using ceramic bearings will be very costly in comparison to usual bearings

took the words right out of my mouth, thanks for saving me the time to type that 🙂

Not to mention it would greatly reduce wear on the gears, since there is nothing between the shaft and the gear

With just 120 rpm I got it going 50 rps using gears

I built a 3d printed fidget spinner that used ceramic bearings and had a steel outer ring for maximum rotating mass. Best hand spin was a little over 7 minutes. Ceramic bearings are next level

Add a weight wheel so you can accelerate slowly but with little increment of torque. The spinning torque will be kept by the momentum of the heavy wheel, so you can add more gears if torque is the problem

there is no way that little power brick can do 350w, that's why it cuts out

it's probably a pwm controller.

Yea, that power brick is probably way underrated for that huge motor lol

The key is, for that 35,000 rpm motor on Amazon, that rating is given with ZERO load. (And that motor is probably not strong enough to sustain that RPM with a load)

So potentially a 2:1 gear ratio attached to it might have such a load as to reduce the motor speed by half, thereby only maintaining 35,000 on the output side of this 2:1 gear ratio.

You need a way better power supply, that brick can't supply the amperage that motor needs, that's why it shut off

pwm controller not psu

@@fss1704PWM isn't magic, if it's a 350 watt motor and you run it at 100% duty cycle you're still going to saturate whatever the power supply limit is. Judging by the thin gauge of the wires connecting to the PWM controller as compared to the motor, yeah he's definitely running out of current

It needs 31-30 amps for that motor

If is a 12v motor

I would also consider teeth design, I recall another creator finding herringbone gears handling the friction problem a lot better when it comes to 3D printing.

The motor isn't stalling. The power supply is being overloaded. Assuming that 350 W motor runs from 24 V, you'll need a 15 A power supply. That one you showed doesn't look like it could do mote than 2!

Your wires feeding your motor are way too small! You're not getting near the output the motor is capable of. The leads coming from the motor are designed to be connected directly to an ESC. If you need to extend these wires you have to run a heavier gauge. In your case you have a smaller gauge wire running to the bigger wires from the motor, no bueno! BTW if you're really trying to get insane rpms you either need to run bearings or tight tolerance lubricated bushings. The motor didn't stall when you fed more power, you had runaway thermal impedance in that tiny wire you're feeding the motor with, I'm surprised it didn't catch on fire!

5:36 Best Quote ever for Mechanical Engineering students

at this point just build it out of metal

Yes

Smart

being more accurate and putting more care into your craft will result in a better product, not just slapping stuff together

If it could hold the weight of a car and still go the same rpm, that car would theoretically move at exactly 3,730.71428576 MPH

a got a few questions:

- why not adding bearings?

- why not adding lubrication?

- why not furthermore decrease mechanical tolerances? its seems to have a huge amount of play

- why not improve on the gearteeth design?

I'm not an engineer but I think it's common sense to add bearing

The motor is *_not_* going to suddenly "stall" as the power continues to be increased (unless it burns out). Instead, it would simply reach a maximum speed. Probably you reached the current (or temperature) limit of your supply's regulator (or maybe the speed controller), and it shut off it's output to prevent damage, until the load was disconnected (or the semiconductor device cooled down). You can check this with a voltmeter across the motor wires.

I was thinking the same thing! Brushed DC motors like the one he showed don’t “stall” since they’re mechanically commutated (they can stall but not in the same way as BLDCs, like the guy in the video is describing)

For speeds like that, ball bearings with the proper C value will be a game changer, every C value is for a particular rotation speed. This will enable you to stop the gears from rubbing and shifting back and forward on the axle. I use C3 barrings up to 20k rpm. Above, you would probably need type C4.

Ever heard of grease? Most gearboxes have a layer of it. Also, like someone else said, torque is the issue in this equation.

Hey, just a thought, you could try to use magnetic gears to avoid friction, plus put gears on a special high speed ballbearings. Eventually, the speed is limited by the material strength, at some point the gear will self destruct by the centrifugal force, so maybe the last gear could be made from metal. Theoretically, few houndreds thouthands PRM could be reacheble

That tiny little power supply will never be able to drive a 350 watt motor.

0:12 blud became McQueen

the large pivots are a high point of friction. make them a lot smaller, or place the gears on bearings. i think the limit for speed will be when one of the gears flys apart.

it is necessary to add massive flywheels that will accumulate kinetic energy and increase the impact force according to the lever rule.

at this point the main issue is not friction, but centrifugal force, because i'm scared it will tear itself apart at 100,000 rpm.

torque multiplication also works the othet way. thay ratio also works in reverse for multiplying the resistance of that gear.

Need to be using bearings on each shaft and lubricant between the gears

some issue you have is also power the wires and transformer you were using definitively doesn't trow 14 Amps for the motor to hold on the 350W

0:21 roughly half a horsepower for anyone wondering.

0.469358 HP to be exact

0:42 CZcams captions : ya that’s sounds like music to me

Said it before, Order some small bearings and press into the gears, And ull notice a huge diffrence

He's a CZcamsr that's decent at 3d printing. He has no idea how to make those design better.

Some big improvements can be made to be honest. First of all bearings would decrease a lot of friction. The second is to use as little gears as possible. There is energy loss in every gear connection you make. Rather use two gears with hughe size difference than 5 in a row. Third every motor has a rpm range that delivers the best performance, depending on the motor type this range can vary but in most electrical motors this range is actually at low rpm.

I don't know about using gears that are as little as possible. That doesn't seem like a sound idea.

But yeah, he should try to find some print files with helical gears in them instead of spur gears. Why use spur gears when you could use helicals? 🤷🏻♂️

Incase you overcome your friction loss issues: Depending on the radius, a 100k rpm shaft speed could cause the gear teeth to exceed the speed of sound.

Speed controller also works as a light dimmer

power supply for the motor definitely cant provide 350w

Maybee 20w lol

you should add a flywheel to the last gear to get maximum output

Lube the gears with Teflon powder.

It's like dry graphite lubricant, but less dirty and way more slippery-er.

What if we implemented this design into vehicles? Would it result in less fuel consumption if the motors are spinning slower gears but putting out a faster rotation?

that's already implemented with those 10 speed gearboxes that are becoming sorta common nowadays. at the cost of stressing the bleep out of the engine, you could theoretically have your engine sitting at idling rpm while driving at 60mph on the highway.

forgot to mention it does impact fuel consumption in a good way, because in a nutshell lower rpm equals lower fuel consumption... theoretically. im not a motor wagon fixer person

I just love watching his videos

Also worth noting that the torque is reduced due to the multiplication, its always a trade off, multiply torque/ruduce speed or multiply speed/reduce torque

I wish microcenter would open up some stores in upstate NY.

Same thing but in Wisconsin or Arizona

Try building a transmission where you can change gears to build speed more efficiently, also try installing bearings on each gear to reduce friction

A great experiment to repeat WITH THE AXLES ON BEARINGS

Time to build a transmission.

for the axles, next time freeze them and then tap them in, then let them seat as they come up to temp

bearings and shims to stop the gears slapping off the stanchions as they rotate

I love how you fidget spinned the variable speed controller at the begining of the video :'D

Haha right

That small power supply surely cant supply 350W?

that thing with knob is not the power supply i believe, thats the speed controller

@@erick2328 at 0:21 it is a small wall adapter (black box) plus the extra long wires for extra resistance

@@billytisme oh yea, i didnt see that, that probably only 5a adaptor

@@erick2328 That's probably a 2A adapter.

I am pursuing an internal combustion engine development career. I think that a simple $100 harbor freight 212cc engine could have enough torque to get 100k rpm

This is insane, Thanks!

How many watts is that power supply. Does look like it can output greater than 350w. Also makes the setup with less parts. And get some needle rolling bearings

If you really wanted high RPM he could get a Castle Creations brushless 7700kv motor when you run it on 4S or 16.8 volts full charge you should get just about 100,000 RPM and you could put bearings in between the shaft and the gears, also adding grease you could probably geared up two to three times skit about 200,000 to 400,000RPM

The RPM and gear ratio was a estimate but the motor should be able to run the high of RPM and don't run it for too long or the motor might heat up

you can also calculate the speed of movement of the extreme point on the last gear, and estimate how close you are to the speed of light o_O

Also there is little surface contact between the gears so any sort of work on it would break teeth.

Maybe use bearings, the friction due to vibration might be really affecting the rotation of the last gear, I could be wrong cause I’m not an engineer 🤷♂️

the plug you used to power that motor i guarantee wasn't enough amps I've used those motors they take a lot use 2 12 volt battery's to power the motor and it should reach 100k rpm that power brick can at most give 3 amps of power and that motor uses 14 amps under load

im so thankfull mate i have an RPM problem with one of my projekts and didnt even think about such a controller

You need a 15 amp 24 volt psi minimum, a wall wart isn’t doing that

Not sure those tiny wires from your power source would even provide enough current to get that motor up to speed

You could've used a brushless motor or a 775 dc motor that can easily top 7k to 30k rpm

Silicon spray lubricant would help wonders

Yes but if you setup the drive wheel to give power to 6 other wheels in a Hex configuration around it could you get each one to make enough power to the drive wheel and a bit more?

Try using some bearings next time. That way the force of friction will be reduced to a minimum, may achieve a higher rpm that can be sustained. This will also increase the efficiency of the system.

Something is telling me that you should try to cut with that..

Your biggest problem is that you are trying to feed a 300w motor with a tiny power supply and when the motor overloads the power supply, it shuts off. Borrow one from a 3d printer and try again.

!! the Ender 3 has a 24v 350w power supply, would be perfect for this motor

bearings and very light oil. that would make the last one spin over 100k rpm

It's over 9000!

worth mentioning you can do a 32:1 gear ratio with only one set of gears.

There is no way that little power supply can feed that motor under load. That motor stalling is probably the power supply cutting out. Get a bigger power supply so you can feed it some proper BEANS!

also amazon has a kit with up to a 3000watt brushless motor that has high rpm that would do great for this and its less then 200$

Tesla turbine with compressed air will achieve the fastest speed you can get with plastic parts.

I’ve been trying to upgrade a fan i have at home and tried various ways of designing gears, but they all didn’t work.

Which tool are you using to get your gears?

Make a air raid siren with this motor, big brain to scare your neighbors

You should build a launcher for bayblades

Have you ever thought of launching a bayblade with this crazy rpm?

This would be dramatically improved by using bearings

Love the video. Would it help to add wheel bearings (e.g., 608 bearing) to reduce friction from the axle. Also, I would be super grateful if you may please let me know how I may get the STL/other 3D printing files for your gear designs. Thank you!

What brand wrench did you use to tighten the axles

those gears flopping around have huge losses. lock down those axles, and get some bearing in there to control your motion.

Very nice video! I like the trend that more and more people printing parts that where you normally would use steel or aluminium for! Good job!

What program do you use for your drawing of the gears?

Im pretty sure your power supply is the limiting factor. The motor can pull way more then the supply can well supply.

You should try plotting those numbers on a graph to find an optimal gear ratio

How do you determine the gear ratio and how do you make it in Blender?

What material did you use to print the gears?

Those are extreme rpms, I did not know a 3d printed part could survive at that speed!

Install bearings on the next set

I think I have an idea to make it gearbox spin fast, so what is of course you start with a big gear and you know attached to a small gear simple, instead of adding a bigger gear to the small gear to the small gear. How about you add a small gear to it that has more teeth and then have a smaller for that gear(with less teeth of course), I hope you get the point

Can You Please Make That Spreadsheet Public to make copies?

Thank You!

Very cool experiment!

So with 43 525 RPM and finally gear with rayon to 2cm we have ((43525(2pi))/100)*60*3.6 ≈ 590 000 km/h ≈ 367 000 mph ≈ 1/500 of celerity.

put a propeller on the end and see how much air it blows

Keep it up, I learned everything about gears all thanks to YOU !!! Greetings from Balkans

Have you tried with bearings instead of directly on axels?

Do you have a download file of the Numbers spread sheet of the gear ratios? Thanks

"Speed. I am speed." McQueen. "SPEED IS KEEEYYYYYYY!" jacksepticeye.

You would need a bigger motor for it to be faster

this is the offical release of the video 2 min ago, the comments 9 months ago was group members n stuff

Dyson vacuum cleaner sitting there at 120,000 RPM

Increase power handling capability of your electric source and and speed controller.

the guy just created fan mode 4

That is the exact same motor as my go cart