3D Printer Gearbox - Spinning it FAST

Vložit

- čas přidán 21. 05. 2021

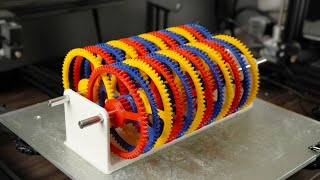

- [Episode 6] This is the fastest 3d printed gearbox that I have ever created. It has a 512:1 gear ratio. How fast can we get it to spin?

BEST ALL AROUND 3D PRINTER:

Printer: Creality - Ender 3

Buy it here: amzn.to/3ASc9Nk

Learn how to design your own things for 3D Printing using Blender:

www.udemy.com/course/design-f...

Watch other episodes of the gearbox series:

Episode 5 - Possible to spin last gear? • Is it possible to spin...

Episode 4 - Generator: • Homemade GENERATOR GEA...

Episode 3 - Drill: • 3d Printed Gearbox + D...

Episode 2 - Speed Test: • 3D Printed Gearbox - S...

Follow along as we 3d print different gearboxes, try different gear ratios, explain the science behind these mechanisms.

Buy the gearbox that was used in this video (signed and dated by me, Steven):

3dprinteracademy.com/products...

STL FILES:

3dprinteracademy.com/collecti...

Support our mission of making 3d printing accessible for everyone:

First 20 Patreon supporters receive unlimited access to premium downloads: / 3dprinteracademy

Recommended Amazon Products:

Ender 3 Pro: amzn.to/3b2znpw

White PLA: amzn.to/3nYEFYB

Copper PLA: amzn.to/2Ssl6fq

AC Generator: amzn.to/3h7yPmh

DC Motors: amzn.to/3eizgYX

Files available on www.3dprinteracademy.com

#gearbox #ender3pro #gears #gearratio #ratio #3dprinted #marblerun #satisfying #machines #tech #ASMR #create #3dprints #3dprinting #3dprinter #workshop #woodworking

“There should be no problem with the box coming off the table”

*Table comes off floor*

But the box stayed in the table 😂

@@kronnie13 you got a point

In the next video he will hot glue the table to the floor. 😃

@@Mr_Yod the floor comes off it’s foundations

@@abhishekvarma3001 That's an issue he'll solve in the video after the next.

Ten videos later: "I'll try to hot glue the Earth to the Sun..." 😃

Put some silicone lube on the gears/shaft, or hook em to ball bearings. That'll really knock out some of the friction :)

This!

Is!

*SPARTA!*

Yes. This! And make somewhat lower ratio and hook it up to a drill

@@Boz1211111 why not just hook this up to the drill?

You need a flywheel on the highest Gear so it stops constantly losing momentum every time you stop cranking

Which would make it incredibly hard to move the crank at all. There is 512+ (include friction) times more torque to spin the crank. There is a reason he made the gears lighter towards the output.

@@1992jamo I'm curious how that would balance. A decently weighed flywheel would take more force to move, but would lose less to fiction. Since acceleration isn't important, it could theoretically go faster. Especially if he started at the flywheel.

@@ZeldaIsMyLove If the flywheel takes 0.5Nm to move, it would take 256Nm on the input shaft to move it. If the crank is 7cm, that's 3657N of force required at the end. That's 373KG of force on that 7cm crank, to get just 0.5Nm on the output shaft. Moving the flywheel first would work, but if it slows down even a little, it would be extremely hard to add energy back into the flywheel.

You would also have to make it stop touching the other gear once you stopped spinning

or to make it thicker

The way you made the screw near impossible to reach kind of makes you a real engineer

@@RepentandbelieveinJesusChrist5

Prosteletyzing is a sin friend. Have some faith in others by having some faith that they'll come to the lord when they need him.

Now as to your ACTUAL comment, as someone who regularly has to assemble/take apart things made by engineers, I blame them for my nicotine addiction, because how tf else do I cope with this design bullshit?!

@@dhuh6760 Sorry you're not smart enough to be an engineer

@@BrowithStoryCool since I got one uh you here, can ya'll get it right?

@@dhuh6760 the vast majority of cars, buildings, bridges, computers, etc and the rest of civilization works how it's supposed to, so it looks like we get it right

Sorry you struggle with using a screwdriver

Truly an engineer moment when the placement of things doesn’t cross your mind until you have to take what you built apart

Look at cars nowadays. It’s almost like it’s made to be difficult to repair.

cars, cars cars cars and trucks, engineers are the worst people ever

Engineer Moment

@@AdamRud47 its almost like technological advancements used up more space and made the car safer by more intelligent design making it so the drivers are the priority and everywhere is a crumple zone

No he had to move it because it would’ve hit the table when he spun it so it had to go off the side of the table

06:01 What we like to see next? Faster spinning Gears of course!

So fast it will make our eyes hurt!

I would like to see him tune the 3d printer. These prints are of awful quality. Elephants foot, under extrusion, and stringing to name a few issues.

....am i the only 1 who wants to see it spinning so fast that it structurally fails and explodes?

Its gonna break

@@anthonymarcelino8460 “If it aint broke, *break* it!”

Use a square rod with a keyway through the gears as opposed to cylindrical. Then you can drive it with a high torque drill. Lubricate the gears. Put a propeller on the end, brace for takeoff

That is wrong if we are using a square rod through the gears ⚙

Coz they have different RPM

@@ramandeep-iu7tc Use a square rod with a steel tube slipped over it for the other gears to run on.

Or drill a hole and use a dowel.

Attach drill and gearbox together, then you may as well developed personal helicopter

Or use a round rod but.. square, D, or key the end for the drive gear.

How to destroy world: put a 10000 rpm motor in the hand wheel

This shouldn't happen

The motor needs a REALLY high torque. If more torque The motor contains more slower is The motor

FBI: *"DON'T FUCKIN MOVE"*

Infrared camera view of that construction would be fun. Would be interesting to see where the Energy gets lost.

friction around the axles mainly, then between the gears themselves. adding some bearings or oil would improve the efficiency by a fair ammount.

That would be very cool!

That's would be great!!

@@heh2393 hey fellow arnav

@@j.c.cannon2112 I also think that the smaller gears get hotter due to a higher amount of friction caused by the speed.

If you have the appropriate tools, try bending part of the metal shaft to make it into a handle itself rather than depending on some sort of glue to hold a handle in place

The next thing to go is the drive gear that is attached with epoxy.

Transmitting forces only through glue connections isn't a good idea.

That's why in real applications gears are normally keyed on the axle.

Making a one piece handle will fix half of the problem tho

Couldn't he just use a modified ratchet extension and use a breaker bar?

Or drilling the shaft and using a rollpin or bolt through the handle and shaft and can use jb weld as well if so choose

Just use a keyway the have bin invented over 1200 years ago and hold much stronger then any glue or weld.

Or screw

or?? weld a crank to it.

I wish you’d put a contrast color line on each one so that the speed of rotation shows up better on camera.

The last ones would just look entirely whatever color you put on

@@FlyLeah that would be beautiful

Watching in 144p be like

Its currently 2 am and im watching this. What am i doing with my life

Hii

for me it's 9pm also who is this NPC guy saying hi💀

@@lennyface987 hii

Brother its rn 2 am

for me its 1am 😢

You should add keyways to the gears and use a keyed shaft

Each gear has its own speed on its respective shaft, keys would bind up the entire system.

If he used it on just the handle it seems like it would hold a lot better

Exactly.

@@orion7353 just to use them on the handles lol ofcourse he didnt mean to weld all gears together u dummy X D

I was screaming this in my head lol keyways on the handle and drive gear

Very cool. Maybe you should key the handle.

Use a file to put a flat section on the axel and then have that slide through the plastic handle, with a lock pin either side.

Some blender render here

@TheRealLoganYT Kind of like how older axes are done so the handle can hold the axe head without worrying about the axe head flying off. If you look up videos of people making their own axe handles you'll probably see an example. Lots of machinery use keys in places where they have rods/axles as well (though positioned differently) because the key becomes the shear bolt so if anything is going to break, it's going to be the key instead of all the expensive stuff. The kind of things engineers have come up is pretty darn neat, god bless 'em

Agree, key all the gears on the shaft, that's how its done in any case where torque is applied.

If it was metal on metal then that would be the surefire way to go. I think a standard size key on such a small shaft would break the plastic. With metal on plastic I'm not even sure I would trust a splines connection. I would go for brazing in a long fat bar into a centered groove on the axle if not 2 of them in an X orientation

@TheRealLoganYT Make it simple for you, Round is slippy

File the shaft to make it D shaped - The flat stops it from slipping

Now attempt to stop it abruptly

No sé puede de inmediato, aún tiene mucho torque

Alternate title: "how to build a really good pencil sharpener"

entire pencil will be just an wood pieces in 10 seconds

@Distance_0 then sharpen the sharpener

@@soda415.5 wait wha-

@@filtztr you know, pencil sharpener sharpener

@@soda415.5 and what if that gets dull?

Last gear was spinning 167 times in a second, that's wow!

thats 10020 rpm. damn

Yes very wow

Then realize there are internal combustion piston engines that turn that fast or faster.

Actually it is 167.000077789 . Get your facts straight. 🤦♂️ gosh.

@@doug112244 And then realize that turbochargers spin at up to 150,000rpm, and can have a service life of 100,000 miles

Nothing like honest clickbait delivering on the common request of "Please just spin it as fast as you can, even if it breaks, that's the point!"

You truly are a gift to this particular CZcams niche.

Took the words right out of my mouth. This was such a simple thing and he did it for us. Super satisfying.

How is it clickbait then? If he does what the Thumbnail states then there is no baiting or false advertisement

@@Barelyalive762 "A caught fish still eats the worm"

@@Barelyalive762 I'd say it's still clickbait, because it's baiting you into clicking on it. Just because it delivers doesn't mean it's not clickbait; it's just not bad/misleading clickbait.

@@Acorn_Anomaly I guess thats true. My understanding of the word clickbait got influenced by the misleading thumbnail meta. Kinda how people use simp in the wrong context.

You should start putting a black mark along the gear at even intrevals, either a single line, (center to the outside), or a pie slice colored in, to allow the casual viewer an easier time counting rotations.

loved the no waste method of using the old handle inside the new one

this man just sacrificed a perfectly good table for a youtube video, props to him

Actually mabey dont give him props, hell probbaly drill holes in them for a youtube vid

Looks like a pretty cheap Ikea Table. So no love lost

It is still perfectly good... Just has some extra holes in it!

Looks like plywood to me and the table is very simple, there's not much money lost there.

He probably made more off this video than the table cost

Can’t believe I watched a man spin a handle

I can’t believe I enjoyed watching it

If there's a thing that goes fast, you must watch it

*”Gears spinning”*

-subtitles: [Applause]

4:36

Lube all the contacts + use router bit bearings between the shaft and the gears, these are made for high speeds, and you'll be able to get faster with the same input force :)

I'd love to see a gear system like this used with a Fan. Just to see how well it could shift air or cool a room.

At what point is it just a manual plane

@@crazynachos4230 When you can crank it hard enough, you need to measure your speed in Knots?

Technically, it heats the room, but you could measure wind speed and calculate a ballpark "wind chill." I'd like to see it

@@SimonJ57 Knots are for ships not planes

@@MonsterPumpkin What are planes if not Ships of the sky? Real talk, airplanes do use "Nautical miles" and knots for distance and speed, respectively.

adding some bearings or at least lubrication to the faster gears to reduce friction may help you get more speed.

insane to watch 3d printed parts spin faster than an engine. great work!

I’ve been thinking the same thing. A little lube goes a long way ( ͡° ͜ʖ ͡°)

Grease to the gears (so that they don't wear) and oil to the bearings (so they are smoother).

Then drill a hole in the shaft in order to have a better grip when glueing things to it.

The only way he'll acheive those speeds is through trial and eror, somethings gonna break. Once something breaks simply reinforce it, if nothing breaks its not spinning fast enough.

@@zN8z trial and error isn't the only approach man. We got the tools to go ahead and be smart about designing it versus just winging it till the end.

@@nap8187 no dur, this is a youtube channel. he makes profit for these videos, wouldnt it be better to have 15 videos slowly enhancing the build each time throughout each video. he could then make more videos rather than one (making more money) . not about it fuctioning, watching his engineering mishaps is whats entertaning.

I would like to see an output side flywheel of some sort. Even adding weights to the final gear. It would make it harder to start but i think increasing the momentum would help maintain speed.

Some ideas from an engineering dropout, rather than substantially thinner gears on the faster end, decrease the infill on the print, you're losing efficiency from the thin plastic flexing as it spins fast. Some combination via trial and error may be needed.

You're never going to get adhesive bond to an axle to hold the kind of mechanical advantage you're working with on the handle, it's surprisingly easy to key a shaft with a dremel and then use a dab of jb weld to secure the key. Lastly, bearings might seem like cheating but you should definitely have something there. Might I suggest brass bushings and a bit of lubrication? They can work a dream and aren't too difficult to make.

I wonder where this series is going?

Don't end this until you reach a million RPM!

I’m pretty sure that’s impossible... with a 10 cm wheel with a mass of 50 g, the centripetal force would be about 55 meganewtons, the equivalent to about 5000 metric tonnes, way beyond the ability of plastics, and even solid steel.

Even Half a million is asking a bit too much

@@andricode 2 million than

@@GRBtutorials Not if we use „Vibranium“ like that Hyperloop company!

This channel is underrated.

No one cares about your channel.

What a shameless plug.

@@serious.business ?

@@serious.business the comment wasn't about the their own channel but the channel that posted the video we just watched.

No

This video was super well made and you have a great personality. Keep it up!

Genius idea with mounting the bigger handle to the smaller one...bravo.

I’m so glad this dude covers all my questions I had before, because none of the other videos did that. They were like “oh it doesn’t work,” video done.

I would love to see you try this again with the gearbox semi submerged in a low viscosity fluid to help reduce friction.

I guess that'll eliminate losses to friction, but is drag not going to be a serious problem? Air has far smaller viscosity that any liquid

Whouldn't just lubricating the sliding parts work better?

@@ngiorgos Cause that's the way to lube it. Oil would just fly off the faster gears just how water flies off clothes when the washer machine is centrifuging the laundry.

@@rafaelmontagner9845 I see your point. Maybe a thin coating will survive just long enough for a record?

Also, what about drag? I think that 9000rpm in oil will have more drag due to turbulence than a dry gear due to friction, but that's just my uninformed guess

@@ngiorgos place the entire thing in a vacuum chamber?

@@Formula7Driver you'd still have friction though

Fantastic!! I'm planning to be a mechanical engineer, your videos are very inspiring!

are you student?

M8

That 2nd handle over the 1st was a 1000 iq move

Replace the lever with a circle, and maybe tie a string around it with a weight at the ene to keep it spinning

Try using a Dremel tool on the "Driveshaft" to allow for the Jb weld to attach better by scuffing the surface

The true speed of this lad

Had to give a like for the elegant piano playing while you vigorously attempt to pull out the last screw

I'd love to see you drive a flywheel with two (or one, two might be too crazy) different gearboxes and try "dumping the clutch" into one that's difficult to drive! It'd be really cool to see the law of conservation of momentum at work :)

Still waiting for the yet unscheduled disassembly event to finally get scheduled! Gonna need a stronger connection from the lever to the first gear though, crazy amounts of torque need to get delivered!

When I was a child, I my dream was to build a plane using a mechanism like this, and power it with my legs. My legs were extremlely strong when I was a child

😂😂

Found you

czcams.com/video/emK-qIbuJ-k/video.html

Did your mom tell you that?

Considering the fact that the majority of general aviation airplanes turn their engines at 2,800 rpm or less and this has 10000rpm this would be flyable.

@@sturmx96 Someone much smarter built a pedal powered aircraft. This required almost a century of innovations for a short low flight.

Always wanted to see a gearbox where the last gear spins so damm fast that the structure can't hold itself and explodes into a thousand pieces due to the insanely high centrifugal forces

Obviously bearings and lubricant would help, I also had the idea to go up by each gear but you covered that here. I think each gear should be solid on the outside like youve done previously. My only other fun idea would be put golf ball pips on the sides of the gears

Golf ball pips would probably not help in this application. Hear me out.

Golf ball pips do increase the range of golf balls by decreasing NET drag, but there are two different sources of drag at play.

First, we have "frictional" drag, where the air that is stopped rubs against the air that is stuck to the surface of the object.

Second, we have pressure drag. I'm terrible at explanation, but imagine a bullet traveling through water. If the bullet was traveling fast enough, as water has momentum, it would "jump" off the nose, and then come crashing back down together. The void that is created is very low pressure, and literally sucks on the bullet, slowing it down. Golf ball pips INCREASE frictional drag, but this energy goes into creating turbulence that extends the boundary layer, or the area around the ball where relative air velocity transitions from matching the ball to stationary. This causes a lower tendency to suffer from flow separation, and thus decreases parasitic drag. The same effect could be achieved by having a teardrop shape, like hypermile cars, but balls must remain rotationally symmetric.

A gear has a constant cross section when rotating, save for the teeth, so I believe pips would only increase drag.

4:34 your gearbox is so powerful CZcams subtitles thought it was an applause

Lost me when I heard "JB Weld is stronger than steel..." But I appreciate your enthusiasm for gears and engineering.

For the handle, grind a flat side on the end of the metal shaft and match that in the handle. Then you get mechanical structure to reinforce the JBWeld.

"the strongest thing I could find....JB weld"

You didn't search very hard apparently

I think you under estimate how strong it is..

The claim that it's stronger than steel is just marketing BS, but if used properly, it's extremely strong. It wasn't used properly here, though, as both surfaces should have been roughed up prior to application.

And the piece of the shaft going into the handle should obviously be any shape other than round.

@@dokols that wouldn't actually give it less structural integrity for the given application...

This is weirdly cool and satisfying and educational.

Dunno if you could use a laser rpm counter. It'll be cool to actually see the measurement

it really grinds MY gears as i saw you screwing the gearbox in a crooked way in the center of the table.

Knowing science behind the things is very very cool

Future him: Lets add 5000 more gears so we can break the speed of light!

thats pretty much not possible

@@exorias625 it's a joke mate

Would it be possible with stronger materials?

@@Mr_Wololo its not the materials you should be worried about

its the energy required to do it

as for stronger materials... well since this one is small then almost any strong metals should work but the larger they get the faster the end gear would spin and after a certain point not even nuclear pasta would survive being ripped apart from spinning that fast

1:2^5009 gear ratio

I’m actually impressed that the last gear didn’t explode

a perfect ratio for my bike, quality built, im likin it

Finally, a video where a gear with ridiculous ratio is turned the interesting way!

Me: I wonder what would happen if I put my hand on the last gear.....

*puts hand on last gear*

Me: Where am I???

Julius Caesar: What strange clothes this man wears

*gets fucking teleported 10 light years away* "The fu- *dies from space*

I might try using a hex shaft with hex bearings. The hex makes it so you don't need to epoxy it and the bearings will drastically decrease friction.

I wanna see a sequential styled gearbox should be pretty fun and interesting to see.

That handle inception is a great idea!

Paint the tips of all the gears with glow in dark ink, feed it some light, and turn all lights off while spinning it.

Or paint it with some green/orange neon reflective paint and turn on a dark light near it.

I have an idea, can you attach a saw blade to last gear and make a manual saw? If it's possible i really want to see it.

i dont think the last gear has enough torque to saw anything

@@minerva474 add mooooore gearsssssss haha

Though this would seem like it would work it would just stop immediately as soon as it hit something. As a sub comment said it wouldn't have enough torque to go through anything and the last year isn't spinning fast enough for the speed it needs to keep going

@@fripsebibs rpm dose not mean workable speed

Yes it has speed but it only has a tiny amount of torque

@@minerva474 you took the words out of my hand as I was about to type.

Can you do a tutorial for this how you printed and designed it

You can also add bearing to the handle's end as it will help you spin the gears with ease 😊

"Give me stick long enough and I can lift the earth" - some Greek guy

Mighta mentioned a fulcrum the fuck you gonna do with just a stick and the earth? BATTER UP

When you're Epoxying 2 surfaces together rough them up some sand paper So the epoxy has more surface area to grip onto

It must be REALLY satisfying to spin that gearbox

It would be great if some small ball bearings are used for the gears to reduce friction on the shaft , quite possible it would help spin the gears even fast due to less friction .

Put a homemade generator on it and use a inverter to boost the voltage of it. 🔥🔥🔥💣👍

The spokes in those last gears might make them lighter, but it's also going to add drag. A solid gear with less infill will the job done better.. It'll probably help keep the fastest gears better in-circle as well. The last several gears would benefit in being balanced. The vibration and wobbling adds a ton of drag and is causing most of the plateau you are hitting. Reducing tolerances between the gears and shaft would help with that as well (+1 on the idea for quality ceramic ball bearings). With those tiny changes, I bet you could go a lot faster, and probably with much less force.

_Brilliant_ move designing the larger handle to fit over the smaller one!

this also means that if you spin the smaller gear really fast you should be able to lift subverting very heavy but it would take a longer time.

Since you are testing extremes, you could remove all internal right angles and replace them with rounded transitions.

Lube all the friction points and secure the handle with a pin or screw.

When I watched how you screwed that thing into the table the first time...I shook my head.

Flywheel at the end and graphite powder lubricant on the shafts for the freespinning gears will get you a long way.

Cool project!

I noticed you use hot glue a bunch... Have you played with UV resin yet? I started using that stuff instead of hot glue and absolutely love the stuff.

It's a bit runnyer so it won't work in ALL glue gun instances but I find it cures just as fast and holds much nicer in many cases

I mean, if you had durable enough materials, and a strong enough cranking mechanism, and enough gears...

You could reach the speed of light.

Odds are though it would require more force to turn than is possible to generate. X.x

it straight up wouldn't budge

more likely to break first

say you have the material from the math universe yeah sure

It fails on all counts, there is no way go generate the force, no material that could withstand the force, and spinning gear would destroy itself

The final gear's perimeter is hitting less than 300km/h. It would take a force 3 million times stronger, with almost infinitely more durable materials to achieve this with the current conditions. Create a zero friction and resistance condition and it would still take a force way beyond our capabilities. And it would still break.

Reaching c for anything with mass requires infinite energy. Only zero mass particles can go that fast.

0:50 JB weld being this dude's reference for 'strong' fucking kills me.

Mechanically pin the handle to the drive shaft a small steel pin along with the job weld will get you going pretty good

hey bro, can i suggest,?

can you put a bearing each of one gear.

too smooth rotation of all gears

Try to cut something with the fast gear. I thought it would be cool to see how clean it would cut through an apple or something like that.

It has next to no torque and would stop at the slightest friction

@@andrewferguson5992 wow, youre no fun :(

@Andrew Ferguson @Nicole Parent realism is more helpful than optimism, when the two cannot align. what's wrong with explanation?

@@thedyingmeme6 wdym?

If you do it again, you can get a 12” 1/4 or 3/8 ratchet extension and use a long ratchet to turn it, you can crank it back and forth to make it easier. That way your drive (minus the gears) will be all metal including the handle :)

That is just so cool. Great stuff.

I love when companies say "stronger than steel" for processes and force that don't really apply to the strength of Steel. It is strong? most likely, but it is such a marketing term I can't take it seriously anymore on like... the tensile strength of balloons or trampolines.

Damn that’s crazy 😐

@@jwaj too much words for your pistachio sized brain huh

@@MrJ183 what did you expect from a kid who unironically posts clash royale in 2021

Put this in a car and it go zoooooooom

Wouldn’t work, it’d spin the drive shaft apart. Throw bearings. Rods etc, an engine wouldnt handle this gear ratio

@@c10chebby69 mid mount motor, transmission stright into the rear end. This would be good for a high torque diesel

Now this would come perfect when you also attach an RC motor at the output hooked with some capacitors, energy on the go.

genius move

PLEASE connect this to a heavy-duty electric motor and just go to town. See how fast you can really spin it!

Imagine if this was solid steel and liked to a tractor's PTO

This video is a perfect example of why you should let practical people design and build things.

I was legit thinking about the table placement as you were screwing it in.

*0:50** Why not Flex Glue?*

If you put everything but the handle in a vacuum chamber and greased the metal very good would that make it easier to spin the gears

wdym

@@TheRealNiktWazny the main factor stopping the gears is air resistance, if it’s in a vacuum the next biggest factor is friction against the metal in the middle and against gears which is why you grease it

@@gerritthompson2246 well I'm pretty sure that in both biggest factor is friction cuz gravity can't be really changed

@@gerritthompson2246 and putting it in the vacuum chamber will make it spin maybe 8% faster meanwhile no friction would be atleast 10x

@@gerritthompson2246 you underestimate friction but if you do both then that 8% turns into atleast 4x

Ceramic ball barings on the shafts, Taller mount so you can move it if needed. A keyway on the handle and shaft connection with a metal washer cover for the rear part up against the mount. A solid handle with a handle that rotates with the gears. Gear (the first gear) that can be locked down onto the drive shift with a keyway or flat ends of grommet screws onto the drive shaft. Maybe a clear cover so you can put a light amount of lube on the gears. Separate the gears on different shafts to make it easier to turn instead of just two shafts. Or put the gears after the first gear on barings.

I feel like this could make for some good workout equipment

Dam that spinning ready fast maybe you should try make a lathe And try do some Woodturning

Prolly not enough torque

But I'm no expert on it

Not the ideal gear ratio for doing work

@@loganireland3113 good point would still probably be a fun video though

When you watch the video 23 seconds after it’s posted but forgot to comment about it 😂

Why is this so entertaining to watch

Your could turn this into a infinite source of energy