How to Make a Larger Vacuum Former | I Like To Make Stuff

Vložit

- čas přidán 23. 05. 2018

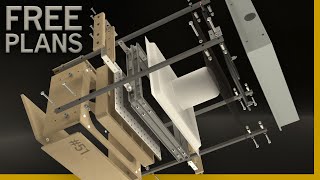

- I'm remaking the vacuum former from my very first project video, but way better this time! Come check out the process.

TOOLS & SUPPLIES (affiliate links):

kit.co/iliketomakestuff/vacuu...

kit.co/iliketomakestuff/shop-...

As many of you know, I don't really repeat projects. Not that each project or video is perfect, far from it actually, I just rarely have the time or desire to completely reinvent something I've already done. If you check out the link for my first project video, you'l see why this project (being far from perfect) is in need of a revamping.

In my previous attempt at making a vacuum former, I placed the material in a frame and placed it in my oven to soften the plastic. This technically did work, but presented a lot of problems; melting plastic where my food goes, taking over the kitchen with a prop-making project, the plastic starts to cool when moving it around, etc. So I found a small space heater that is meant to hang from a shop ceiling to use as the source of heat to soften the plastic.

A vacuum former works by heating up and thereby softening/slightly melting a thin sheet of plastic. That malleable sheet is then pulled down over an object that sits on a flat bed of holes. Once the plastic is pulled down over the object and sealed around the bed, a vacuum pulls the air from under the sheet through the holes and the plastic sucks down into the object's nooks and crannies creating the vacuum formed shape.

To keep the heat source above the vacuum bed, I built a box out of 1/2 inch thick MDF and mounted the heater in it. The vacuum box was built in the exact same way and I used the CNC to drill a bunch of holes for the air to escape. I had to drill a large hole in the vacuum box's side panel so I can attach the shopvac hose directly to the lower box.

Some aluminum angled stock will act as the vertical supports. We guesstimated the amount of sag that the plastic would have when heated and added some space for a tall-ish object laying on the vacuum bed and that was my height dimension. I screwed the aluminum supports directly into the two MDF boxes and the vacuum former took shape.

To hold the plastic sheets up near the heat source and to bring it down on top of the object, you need a material support frame. This is a two-part frame that will act as a clamp on all sides of the material as well as a pulling mechanism that should seal to the vacuum bed. I decided to use some 3/16 inch thick steel flat bar because it would be rigid over the 24 inch span without much support. After welding up the two frames independently, I added two simple handles to one of them. You have to make sure to grind the welds flat, especially where a tight seal would be needed like the bottom and where the material would be held.

Furthermore, I added some simple MDF handles to the sides incase the frame got too hot for my hands. The two frames would be held together with some flat-bottom binder clips and held up near the heater using some magnets suspended on long screws. This will keep the frame in place whilst heating and still allow me to pull the material down with minimal force.

On our first test pull we learned a lot. First, plexiglass is super brittle when vacuum formed and didn't work that great. Second, the space heater's radiant heating area was smaller than I thought, but it still worked well enough. Third, the binder clips prevented a perfect seal with the vacuum bed, so I needed to add some extra gaskets. Thin EVA foam cut into strips would acts as a seal when the material frame sat on the vacuum bed. I lined the outer perimeter with the EVA foam, and then added small pieces in the areas that wouldn't touch the binder clips. This made little notches in the gasket so that I could line up the clips in the same place each time.

Our second test went much better and it was time to switch to some more appropriate, polystyrene sheets. The white polystyrene sheets heated up and drooped like I've seen in professional-grade vacuum formers. I turned on the shopvac right before pulling down the material frames and wham! Good pull. The white plastic sucked down to the vacuum bed and the camera I was forming was wrapped perfectly. It was a success! MUSIC: share.epidemicsound.com/iltms

Subscribe: bit.ly/ILikeToMakestuffSubscribe

Check out my TopVideos!: bit.ly/ILikeToMakeStuffTopVideos

Learn 3d modeling, get digital plans, and cool merch at

iliketomakestuff.com

Want to support ILTMS? Get exclusive content and more...

www.iliketomakestuff.com/patreon

FOLLOW:

/ iliketomakestuff

/ iliketomakestuff

/ iltms

#ILikeToMakeStuff

How to Make a Larger Vacuum Former | I Like To Make Stuff

• How to Make a Larger V...

I Like To Make Stuff

/ iliketomakestuff - Jak na to + styl

Hey, Bob. Glad you are going to be able to vacuum pack your wrenches so they don't go rancid as quickly. I hate having to throw away wrenches that have gone off while most of the metal was still good.

For anyone wanting to make their own vacuum forming machine, here's a pro-tip that will get you great results even as a beginner. You need your vacuum box to be able to fit INSIDE your frame clamp. That way when you pull down your styrene, the plastic wraps tighter around the base of your object bucks. (That means you can't directly fasten the legs to the vacuum box underneath. Unless you make a tiered cake box, where the vacuum forming area is elevated and smaller than the whole box underneath)

I've made several of these over the years, and the most convenient items to start with are actually metal baking trays. Use one to contain your heating elements, and use the other as the base in which you pull vacuum through. Yeah, drilling holes in the metal pan is gonna suck a little more... but the results are more worth it and your homemade vacuum former starts to rival "professional" versions.

Epic tip. Cheers!

Thanks for posting. Would you have pictures of the setup ?

I still worry about the urea-formaldehyde offgassing of generic MDF. I know MDF is a cheap to use but heat will only hasten the breakdown. Any alternatives besides metal?

No uptalk…to the point…no uhs or ands…steady camera…good lighting…well done.

Five years ago i started to follow you with your first vaccum former. Congratulations for your projects and your succes.

Craziest timing. I watched 10 different vacuum former videos with Hayden last night and then this came up this morning! And thank you for the time you spent with her at Maker Faire. She’s still raving about it to her friends. Btw, a scroll saw was the first tool I ever bought her about a year ago. We obviously think alike when it comes to “safe” tools for our kids.

Awesome! Great to have met you guys. Also, make sure you listen to the new podcast that comes out tomorrow 😉

Can’t wait!

I may not make a former like this, but I picked up a lot of other great tips for my everyday woodworking in this video, one reason I like your videos so much. Thanks Bob! Great video

Your vacuum former was actually what got me to sub to your channel, and you've really improved over the years! I have a 3d printer now, but if i ever try my hand a vacuum forming, this is definitely what I'll make.

I was just gonna say the same!

Same here. That original video was one of the ones that got me excited about the channel. Making a good vacuum former has always been one of my goals. Thanks for this new video.

The answer is always MORE MAGNETS! Been wanting to build one of these, thanks Bob!

Magnets everywhere!!!

nooooo the answer is always more clamps haha

Delphine Lam Nah that's in woodworking

EvanAndKatelyn I think Bob must have watched your knife making videos with Alec Steele and liked the "sparks flying" montages! I couldn't help but notice how much grinding he did in this video with sparks flying. I was so waiting for the super slow-motion montage that never appeared!

Like COWBELL and CLAMPS...never enough.

This was by far the simplest version of making a vacuum former I have seen, and I love the simple design of the boxes and how they are connected. I am sitting and planning my own former so this video was great ^^

Good stuff, loving the "I like to make stuff" orange marker. BTW the first build video is actually reassuring for those of us who are just starting. Thanks for hanging in there and motivating others!

Great step by step build. Woodwork, metalwork, welding, CNC, electric wiring and even rare earth magnets, this build has it all! Thanks!

I'm actually really excited to see what you can do with this. One of the more interesting projects of late, especially because of how accessible it is to someone without much experience like myself.

A suggestion- use melamine. As you know, production CNC routers often have vacuum tables and pneumatic dogs. The waste sheet is MDF, with the vacuum pulling through the MDF to secure the cut sheet. That’s because MDF will allow air to pass through, pulling the cut sheet down. It’s permeable. If you use melamine and melamine glue…it’s still inexpensive, but will improve any vacuum carcass you’d build for a vacuum form machine. As a matter of fact, melamine is cheaper than MDF. Trust me…this is years of commercial fixture production experience speaking to you.

Thanks for the tip Ray :D

Totally having tool envy over that CNC, nice build

Great use of many different materials and skills! Wood, metal, plastic... Bob does it all!

:) Thanks dude!

Amazing content as per usual. I love how these tutorials are super doable with a little effort and I love how thoroughly you explain things. Thanks Bob!

Awesome video man, I love how you give extra instructions for people with less equipment!

I made the vacuum former from the other video long before I decided to start my channel... I LOVED that video!!!

Time to make a big one too! :)

I'd love to see how you'd make it!

Giaco Whatever 15 mins could save you 15% on car insurance

I Like To Make Stuff, same. But I'm only allowed to watch this channel. Moms rules :(

We built a massive version of this about 10 years ago for the SAE Baja team I was on. After a form was made, it made body panels for the car in about 10 minutes a set. Huge time saver.

anyone else have no intention of making stuff but find his videos so inspiring??

That's amazing in 6 million forms of communication!

You are doing an AMAZING job doing Instructional Technology content there Mr. Bob! It was great to see you last Saturday!!

0000000⁰0⁰

]]

P],

I’m starting a business, and one element is I need to make my own protective cases. I remember watching the first video on this thing 5 years ago, glad I found it again

Super clever to use a space heater like that! Seems so much easier than trying to repurpose toaster oven heater elements or something. Might have to finally make a full-size vacuum former now!

Sugestion: Move the plastic a few inches further away from the heater, it will take longer to heat it up but you may get a larger heated surface. :)

Some changes that just running through my mind, unsure if they're actually useful.

First ditch the clips, they will prevent getting a really good seal when you press it down, instead have both top and bottom metal frames have those handles then make your wood covers such that you can slide those right on and hold both top and bottom together, then your gasket at the bottom will be much more effective since there won't be any gaps. Another option if you don't want to do that is put tabs around your frame that extend past the gasket then use those to put the clips on to.

Second is your heating element. Instead of having the heating element so close to the plastic, burn issues, make a larger box run the output on the shopvac up to the heating box and create forced air situation so you can more evenly heat everything, and you might be able to use other plastic too. Or if you don't have a virgin shopvac (no dust) throw some computer fans up there to blow the air around.

Lastly is there any issue with the fumes that would be putting off when you're melting plastic?

Its better to make a raised section in the middle smaller than the main beed so the frame wraps around it..

I’ve gotten to play with a few of these at Auburn University, specifically one that does full 4x8 sheets of abs. One trick they use to get cleaner pulls is to use a piece of wood or a silicone spatula to even out the creases. We also just used quarters to space the objects of the vacuum table. You could also try drilling small holes through the object to get more surface detail, a 1/16-3/32 but should be fine for thinner plastics

This is awesome bob!

Thanks again for showing us. You explained it super well!

Nice job, I’ve been wanting to make a Vacuum Former for years.

One tip though, wear a Mask when cutting/sanding/planing MDF, the dust is highly carcinogenic.

What is MDF? Im looking for a good molding resin to pour in to a silicon mold to make a buck for vacuum forming? Im trying to get a mold for my vacuum former to vacuum form hockey masks, but the bucks ive been using for these don't last at all. I want a really rigid hockey mask buck for vacuum forming many copies from.

John Warner absolutely. MDF is even an instant sinus infection.

I'm Eric, i like to watch people make stuff.

Same

Im uriel, and i like to read cool comments

Hi Eric, I also like it. My preference is It looks like a lot of work but actually very simple.

Hi Eric, Im Mentos and Im addicted to diy...

@@MementoNeli hi mentos, I'm Andrew and I'm addicted to mentos...

PS. They are the freshmaker

This Joe, Karna husband. I like your tool rack. It was behind you in this build video. GOD Bless you and your family. Amen

I am just starting on my first machine and wanted to thank you for posting this video. It's not just helpful, it's brilliant, and your explanations are crystal clear. Many thanks for sharing.

Nice proyect! I love your shirt 👍

Very nice bob !!!! Best wishes from the Netherlands

Even though I probably never going to build one, If I ever will I am going to use your video, you have a clear explanation, good tips, clear voice, and the video is not terribly long. great work on the videos!

Thanks so much! That's awesome to hear!

I loved this vacuum former! I would use it for making pop out vinyl signage. Thanks for the beautiful footage on creating this tool!

Thumbs up for the BTTF shirt alone!👍 The video was top shelf as always 👍

Despite the fact the original video was "pretty awful", it was the one that got me to subscribe. Such a great channel and it's been great to watch you and your channel grow and evolve in complexity of build and video quality. Thank you Bob, big fan here

My near 5 year old incomplete box can now be completed! Your build filled in a number of gaps that kept me completing it! Great video as always!

Excellent! Great to hear!

That was very helpful. I am a retired Master Goldsmith. I used to cast a lot. This is something I could have used back then.

A very nice project.

I love your channel it's really crafty and I love this vacuum former

Making a vac machine with an adjustable bed so you can use different sized plastic sheets, so you don’t waste material, would be the ultimate project

So was watching this for the purpose of eventually making parts for my DeLorean, and you're wearing a DeLorean shirt! Fantastic!!!

Cool project as always! You've said in the past you often end up forgetting wearing the dust mask - always do so when cutting MDF. The sawdust of that material is very harmful...

^^^^^^

I expected it to be red and blue since the name of the heater is Optimus!

“Autobots rolling out” 😜🤘🏼

That old video of the vacuum former took me to this channel and i have been here ever since! And im still loving it, seeing you improve!

Awesome! Thanks for sticking around so long!!!

Pretty cool machine! So useful for so many things!

I want to caution you that those handheld masks should be held to your face, there is a significant amount of UV radiation generated by the welder, which bounces off of nearby surfaces and will make it back to your eyes. You should be shielding your face, not the arc, for best protection.

Absolutely correct! You end up with quite a lot of UV exposure otherwise.

Eyeball burns are no bueno. The uv bounces off everything....everything

Why did he resort to using that handheld one to begin with? The only issue was that the battery died in his auto-darkening helmet but it should still provide protection without the darkening feature.

or he could have easily resolved that by going to the store and getting a new battery! cr2032's are not hard to find or expensive by any means... oh well. it gives welders something to cringe at! lol

..... what ever happened to goggles ...... ?

It probably has a unnoticeable impact, but air actually leaks through solid MDF. Sealing the actual MDF surface (even with just wood glue) might have some efficiency gains.

blah Thats probably right but sealing those gaps between the mdfs would help a lot, and the sealing platform and plastic

The paint job probably solved that.

Double Dare Fan the gabs between or the mdf?

Gabs? Did you mean gaps? The glue seemed to take care of that.

I meant the MDF itself, which is central to blah's question.

You could probably start a third channel called "I like to Vacuum Form Stuff" where you just show clips of stuff being vacuum formed. Its soooo satisfying to watch.

Ha! If I had more free time, I might just do that :)

Eu sou brasileiro, seu canal é maravilhoso! Fico feliz quando tem vídeo novo! I love!

Hi bob none of your videos are awful they are rather awsome as always ☺

I wonder if you could make the handles the clamps? If you put metal sticking out on both the top and bottom parts of the plastic 'carrier' you could sandwich the plastic between each part and then put on the handles to clamp it in place. You might need different handles if you used different thickness of plastic but I think it's an elegant solution to the clamp problem.

You could but you also need clamping pressure on all 4 sides. As the plastic gets stretched, it needs to stay put in the frame on all sides.

i commented the same thing then i saw yours 😂great minds think alike.

Also hadn't seen this until after I had posted the same thing myself. What if you gave the steel frame parts a slight curvature so that they apply pressure on the two sides without handles,

like this poor diagram --> top,plastic,bottom = )|(

maybe a piano hinge on one side of the "carrier". Then you'd only have to clamp one side

If you added some tags around all sides and clamp those instead, maybe lower the plastic, so the heater can cover a larger area, it might take longer to soften though..

Wow. Throwback to the old school.

Still learning.

Awesome!

YESSSSS! I've been hoping for a tutorial for a bigger vacuum former for a while now! You rock, Bob!

Great! Hope it was helpful!

"Get better every time." Rule 26. :D Cheers! Chris.

Yeah, it's a saying we have around my shop.. www.iliketomakestuff.com/product/get-better-every-time/

"Get better every time " I like it

Fantastic! New cheer champ possibilities! 😀

As an electrician I cringe when I see DIY's mod electrical devices. While watching this vid, I...cringed, but thankfully you follow it immediately with words of caution and WHY to be cautious. Thank you very much for keeping viewers informed and safe!

I really liked this project. For nothing more that a "cool factor", add a limit switch to the upper portion of the form that turns the vacuum on when you release the frame from the magnets :)

I've been wondering if a heater like that would work for a vacuum former. It's performing better than I thought for a heater that size. Great project!

The simplest is a 'electric grill heater'. It is 110, comes with a heater controller. You can use 1 or 2 depending on size. They are move than 10 amps, so youll need a 110 on a 20 amp breaker, or you will need to plug it in to another rooms if you use 2.

The best way would be to build a pyramid shaped heat box. Going from heater size, to plastic size. That way you get perfect radiation of heat. If you just put it in the center of box, you will get dead spots. Also, the platen, should be smaller than the plastic, so the plastic wraps around the edges of the platen, that will give a much better seal. Your best bet, is to take a look at a store bought vac former, and you will see a lot of the design flaws in home builts.

@@IconicProps That all make a lot of sense. Thanks!

Tool organizer 👌🏻

(1) I think it's great that the heater is an "Optimus"! (2) It's cool that you guys just talked about what past projects you'd remake on the podcast. Welcome back from BAMF!

That was the first video that I watched from your channel and is where my love of watching your video began

i would use it to make molds for chocolate candy molds from lego

Nice project, and cool design (or should I say hot design?)

For the clamping you can also use some small bolts with holes in the vacuum box on the places that they touch the vacuum box, so you have a flush contact and better vacuum. Also for more equal warming of the plastic place it a bit further as I think it is to close and doesn't heat the edges properly, which may turn out to be a problem when trying to form bigger objects.

That's an impressive set of tools you have there, you have a tool for everything! Nice workshop, and a very good video. Thanks.

I bet there's a video about our trip to Maker Faire 2018 on that second channel...and bearded Bob FTW. FIRST!

Is this comment posted an hour ago?

I could be first too if I had a billion dollars in tools.

The P.I. Workshop Josh, what settings where you running on welding shots on the camera?

To keep the camera from blinking in and out, you have to set the exposure so that it stays constant. That's it.

Sounds like someone needs to up their internet stalker game.

could you share the soundtrack at 3:00?

Make the seal to the plastic itself, then you don't have to worry about the frame leaking and the clips won't get in the way.

Adding a fillet at the bottom of objects will stop the spider webs. Also heating the parts to be formed can help

preventing them from setting too quick and then setting them with a spray bottle of water.

Absolutely perfect video dude! It’s so nice to see someone making such an intelligent step by step instruction video without wasting a single frame. Maybe you should go to go to Hollywood. They could use a guy like you! Seriously!

Too late, Bob. I’ve already seen the older vacuum form video. And all the other videos. You’re one of the reasons I started my channel. The other is Jimmy Diresta and Steve Ramsey

Once again Bob, awesome work. Was this filmed at the old house? Looks like the old shop.

By the way, thanks for adding yet ANOTHER project to my list of things to make for our hackerspace (The Make Space in State College PA).

Thanks! No, this one is in the new shop. The original vacuum former video was at the old place. 👍🏼

6:19 that timing with the music and the screws👌

Yes! Watched it again! Well... the first two seconds, and it made me laugh out loud again. By golly you came a long way!

don't magnets start to lose their magnetic properties when heated up ?

Magnets lose magnetism at a much higher temperature than the plastic should ever see for thermoforming.

The Curie Temperature for a typical Neodymium Magnet is about 340°C (644°F) Waaay hotter than even your standard oven.

You're right, some of the rare earth magnets start degrading at rather low temps.

Can you put Josh’s face in there? He probably wouldn’t have to hold his breath THAT long.

Actually, my entrance into the DIY world was the old vacuum former. I didn't even had a youtube account back than. After that I had one ;) Oh man missing the old music. Sweet memories... :D

Thanks for sticking around so long! Yeah, there's no music that would make everyone happy. I just keep trying to evolve things over time and make them better.

You've changed. Change is good. ;) We can always look the old videos, and the videos are still your style. Maybe we can persuade you to an album?^^ Can't wait for David Picciutos album.

I'd use this to organize tools and make dedicated slots for each tool. Thanks for the video, Bob.

8:15 damn, lost me at welding. I could probably do the rest but I’m not welding stuff

Hey, I work as a Thermofoiling engineer and positive pressure vacuum machine specialist for thermoforming at a kitchen door manufacturing company, I can help you fix those problems you're having with the pinching and wrinkling along the sides of the objects you're pressing. There are also a lot of variables that aren't considered (like preheating time and your shop vac ramp up speed while forming) in this build I can help with to make the outcome perfect just send me a message

Please share the tips here if you can, we would all benefit from them :)

Laser Man if he doesn't care enough to send a message then why waste my time

I'd bet Bob is interested, but if you listen to his podcast you know his time per project is extremely limited, this one is done and he probably doesn't have the time. But the spirit of this channel is teaching, sharing, and learning together. Whether or not Bob has the time to personally reach out to you, there are tons of people here who would love to learn from what you know. Unless you're only interested in helping Bob, then none of that matters.

Well, I guess because it would benefit everyone in the maker community to share your expertise. Pretty much anyone who took the time to watch this video would be interested, and certainly anyone looking to build their own machine. These channels are all about sharing information and gaining knowledge, so it wouldn't be a waste of time at all, I reckon just telling Bob the info would possibly be more wasteful, as the information might not end up going out to the wider audience. I hope you can take the time, as I am genuinely interested.

seropserop

I kind of feel sad for you

Nice project Bob, should come in handym for all the different things you dabble in.

Thanks for sharing.

Nice work. Two remarks:

Neodymium magnets loose their power when heated above 90 deg centigrade - irreversably. A snap-on lock might be better on the long run

Industrial vacuum fomers use a two step push- and pull-process. Specially when copying high rising molds, they first blow up a bubble in the sheet, then move in the mould from below, and finally apply the vacuum. That enhances the wall thickness in vertical surfaces. But more than a diy project. Reversing the orientation (sheet on the bottom, mould mounted above it) could be a way to go. Hot air instead of the IR heater could also help get it heated more evenly.

FYI, Actually, your eyes are safe even if you have no battery in your welding mask. The UV-blocking properties is there all the time - it's just uncomfortable to look at.

bright lights burn retinas too. Uv or no UV

I remember the first time you made this! Great improvements! Bob I've seen you make a wood long board, you should totally do a Wooden Paddle Board. They're pretty sweet, and they look challenging! I'm making on myself right now and its a lot of fun printing the template out cutting the ply wood for the spine/ribs. Pretty pumped for the final product!

Great project idea. I'd use it to make festive or themed party globe covers for low voltage outside lighting.

to seal the box right you have to paint it with epoxy.. MDF is pretty breathable and is even used to suck down pieces onto a cic-router-table.

I really enjoy all your videos!

Awesome project

3D posters is a great usage of a vacuum former, typography and graphic elements. As the sheet is so thin it looks great on a wall.

i have 2 notes :

1) what could help and what usually is done is a pre blow which stretches the material so when it lands on the object you don't have to rely on the vacuum that much .

2) is that when for example you do your camera , you should tape of the holes on your board except those within an inch so that the vacuum is strong where it needs to be.

love the vid FYI

If you want a good idea how to vacuum-form plastics, find a place that makes orthopedics. We use to cook our plastics sometimes on top of fabric in an oven on a large silicon sprayed aluminum sheet. Once draped over the vacuum box, the cloth would be removed since it prevents the plastic from drooping all over the place handling it from stove to vacuum. To do something like the head you did, I would make a cast of it out of plaster with a vaseline'd vacuum pipe in it. The cast would have fabric or nylons over it to promote a vacuum throughout the part. The plastic would be draped over the cast, pulled around and then stuck together, working your way up to the vacuum pipe. Once you squeeze the plastic (wearing appropriate gloves the entire time) off at the pipe, it will suck completely around the cast. You can also heat up foam and use a plastic bag to seal it to the vacuum box or pipe. Once cooled, staple it to the cast to hold it in place, rough it up with some course grit sandpaper and pull plastic over it and the two layers will stick. We often used 'white' plastic that you knew was up to temperature when it went clear in the over. If you're using plaster for casts, you can shape it with car body files and smooth it with wet screen (like from a screen door). But note if the plaster hasn't had time to dry out, you can pull water and plaster right off the cast. If one was using plaster for laminating instead, some seal it off first.

BETTER EVERY TIME!

Very cool build. I've been wanting to make one of these but the biggest hurdle was the "cradle" system to lower the frame holder to the vacuum surface. The fact that you skipped any type of complicated raising/lowering system by simply using a separate plastic holder and magnets was a smart move. This reignites my desire to make one of these machines. Good job (as always).

I would use it to make the ultimate tool box. Never have a rattling tool box again, everything would stay where I wanted it to be!

You know I’ve been watching other build channels, but your stuff is by far the best.

Another nice one! Watching the plastic form is so sweet...

Thanks man!

genius project and well thought out. your videos are a pleasure to watch

That's very kind, Thomas! Thank you!!

just a suggestion, if you were to suspend a Plate of stainless steel under the heater and use that to creat a more even heat when you bring the plastic up. i might even allow you to get the full area you were looking for. might take a little longer though depending on the thickness of steel

CZcams know what I want, I just think about it and CZcams recommends that to me awesome,

By the way great job I saw this video already because I have subscribed your channel a years ago so this is 2nd time I'm watching this

Another stunner - nice work man!