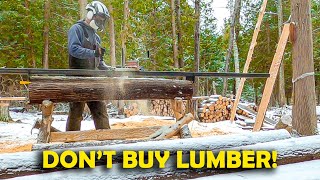

INSANELY EASY CHAINSAW MILL TEST DRIVE! + First impressions VS homemade mill

Vložit

- čas přidán 29. 02. 2016

- In this video we make our first cut with an Alaskan chainsaw mill and compare it to the homemade diy chainsaw mill we've been using.

Granberg chainsaw mill: amzn.to/2azb6LO

Chainsaw mill vs bandsaw mill: • DO NOT BUY A SAWMILL T...

ENJOY THIS VIDEO? SUPPORT US WITHOUT PAYING A DIME!

It takes us 40+ hours a week to document our journey on both our blog and our CZcams channel. If you enjoy watching our videos and want to help us to produce more of them, learn how you can help us without spending a dime! purelivingforlife.com/support/

A quick tip to help your chains stay sharp. remove the bark from the logs. The bark holds a lot of dirt and the bark itself will dull the chain itself faster than clean wood.

I enjoyed the video. You explained things clearly, without humming or hawing, or studdering. You knew what you were talking about, and didn't waste time repeating yourself or forgetting what the video was about. Good job. I will check out your other videos for sure. Thank you.

this is not the first time someone on the internet said I would gain an inch of wood. this is how ever the first time I believed them

I run the same mill with a Husqvarna 395xp. I have a modification to suggest that I have done to my own mill that made the milling much easier. I moved my handle down towards the tip of the bar and installed a hand winch from tractor supply company (like the ones you find on a boat trailer) with para cord and a hook on the end of it. You run the line out to the end of the log to an anchor point and slowly crank the handle on the winch as the saw is running threw the slabs. Makes it a lot easier on the bach and arms.

great job guys (your wife too), enjoy your videos, looking forward to others, watching your homestead grow.

Don't forget to flip your bar on each chain you swap. Wear out both sides evenly

Excellent tip!

You guys are awesome. Love what you're doing.

got to love the smell of fresh cut lumber in the morning smells like victory. welcome spring!

YESSSSS!!

Thanks for the review. I am definitely buying one of these.

First mill i have ever seen set up and in use.. Good job well done... Nice planks ..

Great job on the review. Planning on possibly getting one. Thank you and hope all is going well!

Back in the late 1970's when I was building off grid on Whidbey Island, WA. Had a portable sawmill come in to mill my lumber to dimensional size for under $150 per 1000 board foot, much less sawdust. Air dried with stickers for a year before using. Worked good for me. Wish that I had your information way back then, took me eight years to build my 1400 sf two story house...

Great review. I really enjoy your videos.

Great Video guys as always. Keep on living your dream.

Thanks for explaining so well! will come in handy for me later.

As always Jesse, great explanation and Alyssa was spot on with video. 👍🏼

Great video, very informative. Thanks.

Just a thought on drying the planks. If you don't paint or protect the ends of the planks while drying they will split. Just my two cents.

Dale Church he is sawing pine, you do not need to seal pine or soft woods, the sap seals the ends.

Hey you two just like to say wow!What transition from 9-5 to living off the land not easy ,but you seem to be figuring things out.Trial &error works well kind of like word of mouth.I think that pink jacket is awesome, gives a certain chic~to bush work.

Always remember level & square up everything you build.A bad day on the land is better than a good day in the city!

May the force be with you!

I run an ms 661 with my Granberg. I have a 36" bar setup, and use the auxiliary oiler. I try to keep my bar perpendicular to the work, and use milling chains to get a pretty good finish. I'm looking at building a milling table to be easier on the back. Looks like you've got it figured out, but I have to agree you should wear some chaps, especially since when milling, we put our selves a lot closer to moving chains than in conventional use. You have graduated from safety chains when using these big boy saws! Keep up the good work! Look forward to more updates on different projects, and uses.

Great video and review! Enjoying the channel.

Pretty impressive chainsaw mill. TFS

I've had my Granberg on an E20 with a 32" blade for years, cutting 20x40" ice blocks into 4,5, and 10" slabs. Works great, since the blocks are only 40" tall, I go vertically and the bar walks it's way down with very little effort. Like the guide for the initial cut, thanks!

Don't forget to add the Granberg mini-mill to the homestead tool shed! With 2 chainsaws, one for the slabbing mill and one for the edging mill, makes things go a lot faster. 2 chainsaws means not having to switch the saw from one mill to the other saving huge amounts of time.

Jesse/Alyssa, I notice you are building on concrete piers, keeping the wood off the ground. What are your thoughts/fears on termites, using untreated lumber? Or using termite resistant wood on your vertical posts?

this is soooo cool think of it your children and your childrens , children will always have something to see and to know where they came from.thank you for that thought

Yep, definitely a good review. I've done a lot of research on these. Looking forward to picking one up. You guys are very well spoken and thorough. Subscribed! :^) Keep it up and have fun!

thanks so much for the video, we weren't sure if we get one or not!

having pre-cut spacer blocks (used to set between the bar and the mill while setting the depth) really helps too. Enjoy!

johnsobj cedar shims

Nice review guys. With all the work you have ahead of you please be safe.

Thanks Donnie! Always appreciate the reminders!

Curious why you built a wooden ladder. Would it be practical to use an 11' section of ladder that is straight, square an stiff against racking?

Great review. Cheers!!

this vid was exactly what I was looking for. Thank you.

have you looked into counterweighting the far end of the jig to offset the fact that the motor end is heavier than the tip of bar end?

Great Job guys

The amazon link shows it currently unavailable. May want to update the link to help with commissions

Thanks for this video!

Great video!

Can you tighten the chain without removing the saw from the mill?

thanks!

Mike

Awesome awesome and thanks for sharing 👍🏻

Your Stihl MS660 makes an unusual noise- sounds like rock music. Do they all do that?

Great videos you guys make, love it. You can make briquettes from that sawdust. Its not so difficult. The ones i made burn for 20min but they are small. Greetings from Belgium

Erik

I really appreciate you doing this video. I have a bunch of hardwood logs from 6"-20" diameter and 6' long logs that I want to mill up to make a hardwood floor for a old house I bought and wanted to know your advice on doing this with the Alaskan mill. I bought a Grizzly 15" planer I was going to use to plane it after milling it. Also wanted to know if the MS-660 is powerful enough after hands on experience or if you would get a bigger one.

very nice video. thanks

Hi, excellent video very helpful!

I got one question left about the clamping of the saw. I see almost everybody clamping the bar at the nose end with an ofsett of about 2.5 inches or about 5cm from the end of the bar. is there a standard for that or do they prescribe something? or is it just random clamping?

like to hear from you.

Regards Robbin

Awesome review! Glad to hear it cut square. Are you planning on drying the planks before you deck?

Let the ladder overhang the log at the start if possible then it will be easier to get going and keeping it straight

Hey Jesse - I'm from SW Oregon, loving all of BOTH of your videos with Alyssa's edits/production, of course! Curious to know how the Granberg chainsaw mill 'balances' out the weight of the MS660 in order to produce a near-level cut. Is there a way to compensate to make the cut as level as the 'leveled' surveyor stakes at each end? Keep on rockin it, you two!! No accidents! Amazing work! Cheers ~ Kevstir

A little tip .Turn the bar over every time you sharpen your chain. it will save your bar from getting worn out on one side. like in this video the paint is wearing on on side.

Good Point .. bar maintenance is important, , , one thing I learned was look at the bar rails, and make sure the chain is not wearing itself INTO the bar, so that the rails of the bar are outside the cutting width of the chain, , some times the rails have to be peened in a speck to do this, and a lite filing job to remove the KNURLING effect cures this. you can not remove too much of the rails, if you do the drive teeth will bottom out in the bar, and wear the drive teeth out, and you loose the grip of the teeth in the drive sprocket, and derailing the chain may also result.

do you dry your boards and beams before use?

Nice! Those pine slabs look lightweight compared to the oak and walnut I've had to work with!

Works well doesn't it!

Let gravity work for you, raise the starting end of the log much higher than the ending end of the log, trust me this will make it a LOT less work for you, it almost becomes self feeding, really try it. You won't have to pivot the saw as much, and you will get a smoother surface, IMHO.

How is the oiling on the bar? With those smaller logs I bet you can get away with just the oiler on the saw, but if you get into larger logs, you might want to think about the oiler, it will make your bars and chain last longer, which is worth it I think.

Best of luck, and keep up the great videos.

Domo

SPOT ON, you do not need a lot of ''fall'' from one end to the other in order to make it work, but any degree of fall is good, , I have run one of these, and tried to cut one on a slope, , , it is diffidently easier to carry the saw to the higher end of the log than to push the saw through the wood, uphill,

I have been thinking about buying the Granberg EZ rails G1080 but wanted to know if the 2x4 rail you made is plenty good for your first cut.

How often do you have to sharpen the chain . Also did you find that the power head made the saw slant to one side when you get to the last few slabs.

Have you thought about the EZ rail guide they are making now instead of the 2x4 rail

Why did you not de-bark the tree before cutting? Rocks and bits in the tree bark dull your blade and can snag hard.

Thanks for the video. I'm considering purchasing a Granberg Chainsaw Mill and your video was a great demonstration and review. I was just curious, were your logs green or seasoned?

+shadomane Everything was green for us in this use. We have milled up a few seasoned logs too since then. Green cuts easier! Easier on chains too!

love it

what is your rough cut dimension for 2 x 4 stock to allow for drying?

I would have really liked to have seen what was involved when you go to cut the next slab. You know, how much adjustment, setup or what have you between slabs.

power wash the logs before milling, removes loose bark and dirt.

I want one now....

Hola buenas noches día Lupe cual es la cadena de motosierra correcta para hacer tablas? Grqcuas

Good video ,that saw shavings are good for composting toilet, Then when your planting new trees the compost goes in the hole for the new tree.

Yes!! So excited to use the entire tree! Been saving all the bark and dust for all kinds of projects. Zero waste.

I wonder if you use your saw dust to make other product's for homesteading?

Thanks for the video! I guess you could build something like this pretty easy out of aluminium profiles yourself though.

I'm guessing that you have a few ladders of different lengths, so that they will match up with your logs. It looks like the ladder needs to be a little bit longer than the log, but if it's too long it would be awkward. Or do you try to cut the logs to match the length of your ladders?

Thanks guys! Good introduction to chainsaw milling for me. I've always thought it'd be fun to pick up, looks like I'll get a chance here in the near future. I'll check out the Granberg!

Keep chain sharp and no see-sawing the bar and you'll have a ready to use finish for most projects.

Possibly a silly question: Have you thought of putting a counterweight on the other end, opposite of the power head? Should help with the balance.

Excellent job you two! I enjoy watching all of your videos...keep them coming!

What would you recommend as a minimum saw to mill 16inch logs? would a Stihl MS 291 be sufficient? I'm felling pine in my yard and it seems a waste to buck it up when I could be using the lumber for a variety of projects.

It'll take quite a while and you might encounter oiling problems with a longish bar, the minimum I reckon would be 24''. My old husky 66 was just about up to that size but it really amounted to chainsaw abuse.

Thank you, I appreciate the info. In the end, I'll be taking to a mill, which in my neck of the woods are not lacking.

You may want to have your guide ladder boards longer, sticking out over the ends of the log as to make it easier to sit the saw on to get started and to finish. Also, I know it is uncomfortable, but, you may want to wear a dust mask, as with years of sawing in close with a chainsaw or woodmizer mill you may development breathing problems. Just my two cents from many years of it.

Great work on this vid. Do you think a chainsaw mill would work on hardwood like oak?

They work great! Plan on slower cuts and more sharpening.

Good video !

If you do start having a problem with nuts and bolts coming loose, replace the nuts with nylock (nylon locking) nuts or, if you have to, use blue thread locker.

The smartest thing you can do, if you have a lot of cutting to do, is have at least 2 spare chains ! When one starts to get dull, swap it out. Filing a chain saw is almost an art. You can learn it, but I would want an expert looking over my shoulder for the first dozen I did ! You are much better off taking them to a place that specializes in sharpening !

Keep looking for a second smaller saw.< 24" (

Would it help to put a tarp underneath the log so you can collect the saw dust easier later? Thanks.

That totally crossed my mind, but then I was pondering the safety and difficulty that might ensue trying to keep it untangled, out of the saw should the wind kick up. Plus we lack a place to store the sawdust for now. So we just went ahead and worked. Lol. We may just try that on the next round though. Seems much easier doesn't it? :)

Wouldn't the corners stay if you just put heavy objects on it? Or even stake the corners to the ground somehow until you need to pull it up?

They sell things to put large garbage bags on so you can lay on the ground to sweep leaves into.

Would saw dust inside toilet paper rolls be a good fire starter, too?

Have you tried two people, as in one on each end pulling the bar? Maybe would make a cleaner cut and go faster?

Nice video, well done. What type of trees are you cutting?

+John Bladykas We're cutting a pine in this video, but we're also cutting fir for structural things.

what length bar are you using?

en Perú que empresa tiene esos productos gracias

put a winch on the granberg and the divots and angles look more like a band mill. Also solves the tired arm from the constant pressure on the saw.

look into beam buddy,turn your oiler up on your saw,use angle iron for leveling your ladder

whats the maximum width of a tree can you cut with the mill, can you cut a 27 inch wide tree?

How many linear feet will one chain last ? How much do the chains cost ? Will you have to use the cut wood immediately per warping if sitting ? Will you cut the planks

at 90 degrees (cracks between boards ) or at an angle to minimize the cracks ? Continued good luck

Video on chains is in the works! Subscribe if you'd like to be notified when it's available! :)

Hi

Looking at you cutting the lumber I would suggest that you could slide the handle even further to the right and still feel comfortable and I think being able to keep the bar as straight as possible would make a big difference in the quality of the lumber. You would get the best stability if you have the whole board between the saw and the handle but that might not always be possible. It seems easy to adjust so play around a bit more and better to feel comfortable than unsafe.

Excellent product review and teaching vid.

We are considering a Granberg for a group purchase vs a bandsaw mill

Price is close for us since the bandsaw is well used (so less expensive) and we'd have to buy a powerhead as well as the Granberg mill.

Do you have experience and/or a preference between the two ideas?

We didn't really buy the saw so we could mill. We knew we'd be milling so we invested in a saw that could do it all but we knew we'd need firewood too so it's a very versatile tool for us.

We haven't done a bandsaw mill so we can't testify or truly compare them. However my mind is telling me good luck moving logs around. I think milling is pretty straight forward but moving logs isn't so easy. At least for us they're on a hill and that makes it way more difficult. So mills aside think about where you'd be milling. The reason a chainsaw mill makes sense is we need only get them a short distance. Even a portable mill would have a hard time getting where our trees are. So I guess consider that in your decisions too.

Excellent point about moving logs.

Thanks again.

OK now that you have owned this Alaskan for some time now would you buy it all over again. Been wanting to buy one but like most things they end up being a disappointment. Also is the 36" about the largest mill with the MS660 that one man can go with.

You could use the sawdust to make sawdust 1/2 bricks for your wood stove .

I have seen it done on the internet.

Steven Grotte or you could bag up the sawdust and sell it to horse owners who will use it for stall bedding

good job, nice video

+outdoorcountryboy forlife Thanks and thanks!

Not sure if you follow Wranglerstar or not but he has the same mill and does timber framing as well - he has always said to remove the bark from any lumber that you're making I can't remember for sure why he said you had to - I think because of early rot?

We love Codys channel. Nice guy! I think always removing the bark is extreme and not always needed, but with some species it is important because of bugs. Like pine bettle.

Pure Living for Life ahhh - I don't know much about Douglas Fir other than I'd LOVE to have flooring made out of it - it's my favorite wood -

0 or 5 degrees on your crosscut chain may help...also...if the chips are a little big just keep the raker height closer to the tooth height....some other geometry on the milling chain may be different...price difference vs time to modify will determine what is worth it for you.

Extend the runners on your ladder so the saw attacks level. Then it will be more clean at the beginning.

Noticed that after our first cut. It's what we normally do but apparently out of practice after 4 months off. After this video we milled up all 5 logs. Went like lightening after we got things sorted and into a groove.

If you cut bigger logs into lumber do what I did and put a hand cranking winch on your sawmill. It works great pulls the mill straight and saves a lot of labor. I've cut beams 12 inches thick by26 inches by 28feet8inches long. Worked great.

+guy mcelwee I've heard of such contraptions. If we get heavy into beams we'll have to do something. The fatigue will start to set in! Thanks for the tip!

Curious to eventually hear how many boards can be cut before you need to sharpen the chain.

I was able to cut (28) 1.5"x14"x8' slabs before sharpening. 224' of slabs to be exact.

+Pure Living for Life Thanks for your reply. I do some chainsaw carving and might use something like this to make benches.

just a heads up, you should probably think about squaring out the logs first, i dont see it much on youtube but the bark being dragged through all the mud and dirt will eat the chain! maybe a "beam machine" or something similar would help. you could do the squaring with the saw mill but either way its a log of buggerin around lol

Addressed this in another comment below. For lumber you waste too much wood squaring the log. For beams it's a no brainer.

Pure Living for Life i never thought of it that way... hmmmmm we never wasted anything at the mill but all of us worken there burned wood for heat. my only question and no one seems to answer it is how do you ge square wood if you leave a live edge on the stuff ur cutting? if u square it out after wouldent that be just as much wastage? im not sure how particular u are about the thickness of oyur boards but i see a lot of guys on here using aluminum ladders for there first cuts. the wood here is pretty crocked even the No.1 wood we get lol. i wish u guys well bro we'll be starting our home stead soon i hope just waiting for land prices to come down a bit further so we can get hte most bang for our buck!

I have a suggestion for the first cut and end cuts. I made my ladder,double the width of the mill added to the length of the log. so an 8ft log would get about,a 10ft ladder. get a nicer first cut and a no worry end cut,cause you're not supporting half the weight of the saw and mill.

lock washers might help the lock nut loosening...

Sihls are great saws but for big jobs Jonsered's can't be beat

For getting your first cut, try using a straight framed aluminum ladder. Its light and stiff (^_^)

how many cc is that chainsaw and what's the bar length? I'm looking into buying a stihl chainsaw meself that I can utilize for multiple jobs.

+Damian Rivero It's a 660 and bar length is 36". Both are rather large for an "all around" length! We have a smaller one we use for other tasks....

Just wondering why you cut slabs, and not just use the mill to cut dimensional lumber?

+melissa cripps Slabs are milled and then cut into lumber with traditional power tools like a table saw and circular saw.

it's so easy even these guys can use it.