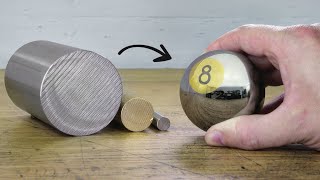

We Created a Thread With a Thread Drill on Manual Lathe / watch full video and learn amazing process

Vložit

- čas přidán 27. 11. 2022

- We Created a Thread With a Thread Drill on Manual Lathe / watch full video and learn amazing process

#threadcreating

#makingthreadwithdrill

#pkprocess - Auta a dopravní prostředky

This guy could go to work in a well stocked machine shop and convert the whole thing into a pile of scrap iron within two weeks. Tops...

🤣

i guess yor right, he could even scrap the lathe

Precision hates this one easy trick!

The wobble in that drill press is glorious

Well, first the trick of putting the round stock in the lath chuck this way is way too dangerous, next the flex of the workpiece and the tap is noticeably excessive, and the taper of the tap prevents it from fully engaging the workpiece all the way to the end. You can see from the Prussian blue the threads are not the same all the way. When he threads the nut on, it is really loose at the beginning and stops before it gets all the way to the end of the threads.

You have touched on only a few "concerns" .....which I completely agree with ......but my fundamental question is ....what's the point of threading with a tap? Why not just "single-point" make the thread and be done? This will generate a far better thread.

.

@@taxicamel

Check out my latest video of how I cut metric threads on a imperial thread cutting lathe.

It will help you understand the point of this video.

But...WHY, he seem to have a thread''feed''on that lathe anyway. Why not just use a 60 degree insert or grind a HSS ??????????

Listen to that knock, knock, knocking sound at 8:00 while the part is turning; the bearings are ruined in the main spindle of the lathe.

Tiện ren như vậy thật là một ý tưởng điên thức tế chẳng có một thợ tiện nào làm như thế này cả

I've been a machinist and toolmaker for 49 years and this is the most asinine thing I've ever seen. Forget you've ever seen this

Dude that's exactly what I thought. Just a total waste of time....

I'm a retired machinist so crude its unbelievable that they really think they are doing good work the nut was just hanging on because of gravity pitiful

I don’t know I like a demolition derby too its destructive

I've only been in the game for 20 or so years, and thought the same thing....

Да вы очень правы !

the "device" you're using is called a "TAP!

It's called a TAP, not a THREAD DRILL.

You're crazy to hold that part with your hand while drilling it!!!!!

Well he is Asian,, so many Asian people has tough magic hands😅😅

Oh puhleeeze more safety Nazis

LOL i saw that and thought to myself well say goodby to your fingers

Кажется люди не совсем понимают принцип работы инструментов:))

Когда все ушли,охранник показывает «мастерство»!!!

There are a couple of things working against him. He's trying to compensate for the taper on the tap by running it well beyond the end of the threads on the workpiece, but the workpiece still is winding up with a slight taper to the threads.

I think a bigger problem is that the threads closest to the end of the workpiece are engaged the entire time the tool is cutting, while the threads on the end are waiting for the cutting tool to arrive. If it takes 12 revolutions of the spindle for a pass, the first thread will be cut 12 times _more_ than the last thread. Whereas with a single point tool, each thread is cut once for each pass.

In other words, he's doing it the hard way!

I'm still trying to put it together in my mind of how threads on each piece stay lined up enough to make multiple passes. The only thing that clicks is the speed of movement must be the same for each pass.

@@Wildwwill power traverse

@@Wildwwill The lathe has been set to do screw cutting at the correct pitch. The lathe also has a dial on the apron that indicates when the leadscrew can be engaged so that it picks up the same threads each time.

@@rolandburisch9489 Interesting.

C'mon give him credit,it's a proof of concept,I'm a 2nd generation machinist been in the trade for ,32yrs qualified,and even longer before I started my trade, and I think it's great,

Привет всем,всё задумки хороши,только режущий инструмент надо выставлять правильно,а не выше центра.тогда работать будет весело,да и качество обработки повысится.

Одним резьбовым резцом работать при разных операциях будет грустно, как не ставь. Метчик предназначен для нарезания внутренней резьбы, а резец для наружной (которым он протачивал)😢

Crude way to cut a thread. But you got lots of people, including me, to watch your video so you got some money from CZcams. Carry on.

Hasta ahora va por mas de 20 mil dolares.

El que sabe trabajar, trabaja, el que no, enseña

Buen trabajo!!!!

That's a total waste of time there is too much surface contact creating flexing and a very rough finish.Surely you would have a piece of HSS to sharpen a single point tool and cut the thread much faster and better finish.A little lubrication might help.BTW it is not a thread drill it's called a TAP.

ตตีีีำ-จฟ

ๆ

ขายาวขง

ขขลล

ลงล

ข

ข

Most of these guys

demonstrating machining from parts of Indonesia don't understand what machining really is. Take mekanik messin from Indonesia; he is definitely not a machinist. Take a look at how he operates. His shop is also a "death trap."

When you finish looking at mekanik messin take a look at Joe Pieczynski, Advanced Innovations, LLC. from Texas, U.S.A. The difference between the two is like night and day. I was a CNC machinist most of my life but I started out as an old-style machinist trained by, Germans brought over to the U.S.A. under "Operation Paperclip." I learned alot of fine machining techniques which I used in both my shop and later in life at a CNC shop.

When he says manual Lathe I'm assuming it has no power feed or threading capability to sync the carriage with the spindle RPM. I get that but I don't get the need for stick-out here. He's using a Tap externally to do essentially what a Die does. Wouldn't it make more sense to support both ends of the tap? Doing it like this is begging for a broken Tap. The damn things will break when you do everything right. So, there's no need to invite it! vandalsgarge commented about the Tap's taper and how it will effect the depth of the threads. He's correct but the tapered nature of this type of Tap isn't even needed in this operation.

Wakodahatchee Chris

I found this in my saved links. It essentially shows what I was describing. czcams.com/video/hDaNnpatDDs/video.html

Keep it Up 👍 ❤

Good job 👍

За креатив - лайк. Но вообще то в этом методе много минусов, которые я не стану перечислять, потому что автор ролика и сам их наверняка знает.

даже я(не токарь) заметил парочку.

Why not just use a 60 deg threading tool?

He use the 60deg tool for simple machining diameters...

That would have just been way too easy.

Because he is pretending to cut a 3/4" BSW thread which, as everyone who has cut threads knows, has a 55 degree thread angle.

Very creative idea

It’s the first time I’ve heard a tap referred to as a ‘thread drill’

It's all Bullshit LOL

This is a convenient solution if he has a problem with his machine

Keren,,,Ga kepikiran cara bubut cylinder besinya..

I dont see the advantage over just using a standard threading tool

I certainly don't see one. Especially when you see how messed up the form is when he's putting the nut on it. You can see the part drooping in the front. I feel like they're fighting tool deflection because of the length of the tap. If someone wants to work in fractional instead of decimal, they should have just become a carpenter. Stick to spice racks.😆

@@mikemcgannvoiceover ^ Gold 👍

Its NOT a "thread drill" it is a TAP!!!!!!

👏👏👏👏show

Абсолютная пустая трата времени. А просто нарезать резьбу резцом. Зачем изобретать велосипед?

Не понимаю есть резьбовой резец для чего метчиком делать эту работу

@@user-bf9rl3vw4q резьба рваная метчик надо завалить немного

@@user-bf9rl3vw4q ну а как он подавал метчи'к 🤷♂️

@@user-bf9rl3vw4q вот и я о том же

Ótima ideia porém o passo de rosca deixa folga prefiro fazer usando o comando do torno

Super

Thanks for the welding tutorial. It was great.

Mearu. Great

The only machine in the world that is capable of replicating itself is a machine lathe. It can even makes it's own nuts, bolts and washers!!!

I think this lathe operator is really a person with an innovative thinking capacity. If he learns the theories of machining and dos&don'ts of machining operation with technical reasons well, he may develop himself to work safely in higher levels without deviating from the engineering ethics.

?????????

Far easier to generate the thread with a threading tool. A complete waste of time otherwise.

.

i use a die, but i think they love it the hard way....

Most creative to young people to learn

At 4.26 here is a good example of why this guy should have been making screws to hold the jaws to the vice . Here is a challenge for you as a apprentice toolmaker I saw a Russian Toolmaker win a bet when he cut a left hand thread into 12 mm thick plate using a Right hand tap . And yes it can be done I lost money betting it can't .

Very good

Good

I think reason the nut stopped half way was because the threads weren’t cut correctly the entire length. Before filing notice how there was more blue ink towards the relief cut. But you got an extra view from me. Mission accomplished.

The tap was tapered so definitely not getting full engagement. Also there was definitely some deflection going on. It's a neat trick but not practical at all. A die or single point threading tool would be the way to go. The surface finish on this thing is horrendous.

????????? .... You need to stop and think on your own.

Far easier to generate the thread with a threading tool. A complete waste of time otherwise.

.

Mantap x bos

josss...

Ông xong 1 cái thì tôi xong 30 cái rồi.

Your lathe has screw cutting back gears so why not just cut the threads with a single point? If you really **must** do it this way, then turn the toolpost slightly so you don't get so much of a taper.

No coolant used in the hole process

@@johnsplaine3236 You dont need typically coolant for external threading. Maybe a little lube on the last few passes but coolant isn't doing much if theres nothing to cool

Hello idol wow👍👍🙏

But, you still used the half nut. Cool idea for getting round ASE threads

Excelente trabalho 👏👏👏🇧🇷🇧🇷🇧🇷

stpidity in brazil has no boundaries

wow putting a flat on round stock on a worn out lathe reminded me of high school machine shop

Espertao..... kkk... precisa de umas aulas !!!!

I COULD HAVE MILLED THAT FLAT IN 2 PASSES,.. BUT IF ALL YOU HAVE IS A LATHE TO WORK WITH HAVE NO DIES AND JUST TAPS, IT WORKS!!!

Single tool would have been soooooo much quicker.. This has no advantage - However very different thinking though..

Clickspring could learn a thing or two from this guy, lol.

The first time ive heard a tap called a thread drill, also a lot quicker tò screw cut.....

As a novice,40 years ago I would make a key way on a shaft attached to tool post and mill bit in chuck.thought I was shit hot but that chunk of steel in the chuck is scary.

Я токарь 5го разряда, у меня потекли кровавые слезы.

زبردست بہت خوب

It absolutely sucks making it this way, but I did watch it so well done

👍👍👍👍

That nut was WAY too loose.

It won't hold under a load. I doubt it would even tighten without slipping.

Oh very good idea thanks my God Blass you u secced all your life

Когда он напильником через патрон,,,думал ща его намотает,

einfach genial!

Clearly didn't work as the nut got stuck halfway up the threads. This is because the method shown requires synchronizing the rotational speed of the lathe with the linear speed you move the tap to get the right thread pitch, which manually, is virtually impossible, and certainly can't be done that way with precision. This is why you buy a die of the right size. Lots of work and wasted material to get a complete lack of precision, resulting in failure.

I question your response and in a polite quizitive way....On my LeBlond lathe, when I chuck in my thread cutting tool on my tool post, it is no different than the videos tap....just as long as the thread pitch per diameter of the work is the same, its just that the video is capable of having more "teeth of the tap" cutters in a row instead of single. When I cut threads, I can slow or speed up my chuck ( rotational ) speed per type and size of material I want to thread. Example: If I want to cut 1/2" -13 ( nc ) threads, I set my carriage speed for that thread pitch, so the carriage is going to move the same speed regardless of what is in the toolpost ( tap or thread cutting toolholder ). IF my chuck spins faster, then my carriage runs faster too, but still in the same ratio to retain that 13 pitch. Also look up Vardex threading inserts. These are actually doing the same thing as the tap is, only the inserts are mounted in a toolholder, similar like inserts for an indexable endmill or facemill. I think the reason the nut did not go on the full way is either : 1.) the tap was not positioned perfectly parallel to the stock or 2.) another pass should have been made to "clean up" the threads, or 3.) he did not have the O.D. cut down enough.... or 4. ) the chuck is not dead centered ( meaning the shaft is "camming" ) or he has spindle and bearing wear or 5.) the tap is worn . I'll agree, that a die would probably make up for these errors especially in concentricity, but this is not a bad idea to try if a guy was in a pickle and did not have any special tooling on hand, and had to make do with what he had say for like a "meatball surgery one up fix on a late night or weekend". I would not do any "production" work this way.

the nut got stuck because the thread is not finished. The second half did not see the end of the tap, you still see blue ink there.. The tap is conical, and to finish the piece, you'll have to pass the whole length, which is impossible with this workpiece.

But why bother set over the compound slide and select the correct gears and grind up a piece of hss for a threading tool. Perhaps that is too easy.

In order to grind a tool you need a 60deg template to gage it off of, maybe he doesn't have that? Maybe his lathe doesn't have a compound slide, and maybe nobody taught him how to do that.

@@integr8er66 Compound slide is clearly visible 5 seconds into the video again at 2:14. He has to engage the half nut to advance the tap to try and cut the helix correctly. The blue clearly shows thread is being cut unevenly so nut spins on and comes to an abrubt halt. Pause again at 9:25 and you clearly see the first few threads are wafer thin compared to the rest. This is caused by not having a single tool cutting the helix. I guess if ifs and buts were candy and nuts, we'd all have a Merry Christmas.

Chasing a thread would be so much simpler . I can hand grind the single point tool much faster . I get paid to be efficient not waste time .

Ahhh... the old thread drill trick

Не понятно, это когда нет плашки, а есть токарный станок?

И даже есть резьбовой резец! Но! Резцы надо уметь точить,а практически во всех роликах от этих работяг используются резцы без какой либо заточки.А вот метчик имеет идеальные углы заточки .

Любой токарь может заточить резьбовые резец. Образец угла заточки сам метчик.

@@user-pn8pz3bv4i я видел очень много роликов о пакистанских токарях....и из сотни только у двоих были более - менее заточенные резцы....причем обычные ,проходные.

Так ,что утверждение о том,что любой токарь может заточить резец ,для пакистанцев недействительно.

А для заточки резьбовых резцов обычно используются специальные шаблоны,которые в кругу токарей называют рыбкой.

Это когда делать нехрен.

"Watch and learn.. amazing!" Wow??

What I learned is, this is amazing nonsense.

Single point threading is the way to go if you don't have the right threading die.

I used lathes for a long time, but didnt know u could put a piece sideways between the jaws .. lol .. alot faster than milling it flat.. :)

LoL, my thoughts also, but definitely looks dangerous if it comes loose.. 😱

Not sure it’s faster than putting it in a milling vise and making a few passes. Also, a lot safer on a mill.

But, if you ain’t gotta mill, this will work.

@@TBrady26 indeed, many milling operations can be done on a lathe, one way or another. (Frequently, not quite this way, but hey…)

It's not safe, use a four jaw for pete sakes.

@@TBrady26 no machine faster than lathe !

Try it u will see 👍

Bien plus simple à réaliser normalement avec un outil à fileter à 60 degrés sans se casser la tête.

Et avec l'outil monté à la bonne hauteur ça fonctionne bien mieux ( en début de vidéo). C'est du mauvais bricolage désolé.

это все от бедности, обрати внимание что он использует резьбовой резец вообще для всего, потому и такое решение.

He is pretending to cut a thread using a 3/4" BSW thread tap with a 55 degree thread angle.

Good job,nice🎉🎉

Your turn tool is above center

Eish !!!

Machine dee

👍🏻👍🏻👍🏻

Hells teeth!!!! The most dangerous man ever to be let loose in a machine shop.

I always wondered if anyone did this, now I know

why doing it the simple way when it also goes the hard way?

Станок бьёт не вооруженным взглядом видно

Половина сверла в заготовке осталось?😂😂😂😂😂

안녕하세요 ㅎㅎ

감사합니다 ㅎㅎ

Sangat bermanfaat

Interesting technique but sloppy threads. I would use a die or single point or both.

True, but if you want a non standard thread you won't find a die that will do it, say you want a 1" 20 TPI well you can use a 1/2 - 20 tap on a 1" dia piece of stock and get it done. Yes single point would be better if you have what you need to do it that way, but sometimes you don't have every tool needed

well!!! I now can say I saw this!!!

Świetna jest zrobiona robota pozdrawiam twórcę tego filmiku 👍👍👍👍👍

The nut got stuck halfway up the threads, meaning the thread pitch was wrong or irregular. Total failure.

Kup sobie słownik ortograficzny i naucz się poprawnej i bezbłędnej pisowni. Aż przykro czytać.

At least we can be confident he's wearing his saftey sandles

Youre all great critics. These fellas work with what theyve got.

"A thread drill".....LMAO.

Одним резьбовым резцом молодцы

другого нет😄

такое показывать, это уже тупик полная глупость

Бьёт уже не хило так)) нужно же аккуратнее с машиной работать.

С таким успехом и пиписку сломать можно

Very good idea thanks

put NO standard

The tap is (was) the only decent tool in the workshop. Now to finish the rest of the set of high precision wheel bolts. What could possibly go wrong...

Why not just use a die holder in the lathe tailstock?

Probably because he doesn't have a die or even a tap in the needed sized but he does have a tap that atleast is his required pitch. Is a good idea for a one off screw or nut in a pinch with stuff that'd be on hand and little to no time to wait for delivery of the correct tools

Salut. Quand je vous vois tenir la pièce à 2 doigts pour percer et bein je voudrais pas prendre une claque 😅😂. Merci pour la vidéo 👍.

Do you have a tool that runs true ? that drill press cracks me up ..LOL🤣😂

Good teknek