Thermal management: liquid cold plates welded by FSW - Friction Stir Welding | Stirweld

Vložit

- čas přidán 24. 07. 2024

- The liquid cold plates are composed of a housing and a cover, to close the water channel. That is why it needs to be sealed, for which Friction Stir Welding is an ideal technique.

The advantages of FSW welding over other welding techniques are:

- Lower cost (Replacement of EBW or vacuum brazing)

- Higher resistance (up to 300 bar)

- Perfectly waterproof

- Excellent thermal conductivity

- Extremely user friendly, compared with EBW or vacuum brazing

In addition, with the Stirweld FSW head you will greatly reduce your investment cost as you will be able to weld directly from your CNC machine.

If you have any questions or suggestions, please contact us at contact@stirweld.com

Visit us: stirweld.com

👉 Follow us on LinkedIn and keep up to date with FSW technology! / stirweld

Chapters:

00:00 Introduction and summary

00:11 Tack welding

00:31 Trajectory verification

00:46 Parameter setting

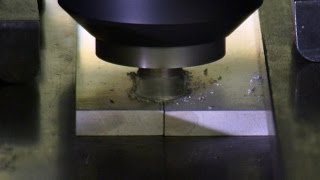

01:08 Friction Stir Welding

01:48 Milling phase

02:12 Heat sink welded by FSW - Věda a technologie

I learn a lot..

Which sacrificial material is used beneath the liquid cold plated?

Hi! There is no sacrificial material. Thank you for your question 🙂

Could CNC be used for FSW?

yes absolutly, thanks to Stirweld FSW head for CNC machines. Have a look at stirweld.com