The Real Reason Tesla Developed The Plaid Motor!

Vložit

- čas přidán 17. 05. 2024

- Start speaking a new language in 3 weeks with Babbel 🎉 Get up to 65% OFF your subscription ➡️ HERE: go.babbel.com/t?bsc=1200m65-y...

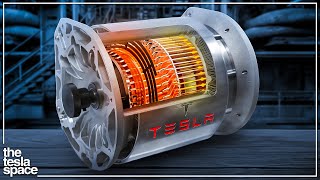

The Real Reason Tesla Developed The Plaid Motor!

0:00 Start

1:11 Nikola Tesla's Design

4:14 Inside the electric motor

6:44 Babel

8:06 Inside Tesla's plaid electric motor

11:32 The Munro teardown

Last video: Tesla Gigafactory Texas Is Expanding!

• Tesla Gigafactory Texa...

► Patreon: / theteslaspace

► Subscribe to The Tesla Space newsletter: www.theteslaspace.com

► Join Our Discord Sever: / discord

► Subscribe to our other channel, The Space Race: / @thespaceraceyt

►You can use my referral link to get 1,500 free Supercharger km on a new Tesla:

ts.la/trevor61038

Subscribe: / @theteslaspace

Welcome to the Tesla Space, where we share the latest news, rumors, and insights into all things Tesla, Space X, Elon Musk, and the future! We'll be showing you all of the new details around the Tesla Model 3 2021, Tesla Model Y 2021, along with the Tesla Cybertruck when it finally arrives, it's already ordered!

Instagram: / theteslaspace

Twitter: / theteslaspace

Business Email: tesla@ellify.com

#Tesla #TheTeslaSpace #Elon - Věda a technologie

When turning, the inner wheel needs to spin slower not faster. An easy slip.

Thank you

Exactly… this guy doesn’t even understand the basic concept of why you need a differential. The inner wheel has less of a path to travel and the out wheel needs to spin faster because it has further to travel when turning. Duh….

Yup just like regular car rear differentials

Boo... That's what I picked up too! Still trying to figure out if these are Easter Eggs or genuine fumbles...

@@GET2222 Hey easy with the nasty!

To turn or go around a circle, the OUTER wheels have to spin faster not the inner, as stated here!

Indeed, heard it too 😂

No, it's correct. The inner wheel slips and speeds up to match the outer wheels.

Electric motor designer here.

Great video. Even though simplified a lot at some points, I think you got your points across well.

However you got some things wrong about the carbon fiber sleeve. Carbon fiber is terrible at conducting magnetic fields. Therefore, if you have a 3mm thick sleeve, from a magnetic point of view, its like the airgap is increased by 3mm. So the effective airgap is actually much higher with a carbon fiber sleeve. What carbon fiber is good at is preventing the rotor from destroying itself due to centripetal forces, allowing higher rpm. With higher rpm a very low aigap is actually not desirable due to increased rotor losses, but this is a complex issue.

I'd love to chat about this with you, if you are interested let me know.

Im an electrical engineer.... how did you break out into electric motor design?

@@cyberlando Well I worked at a company, that produces electric motors, while I studied.

Fellow electric motor designer here. Surprisingly goes unmentioned but the carbon fiber sleeve also lets them get rid of the flux bridges between the magnets, essentially they break the rotor into separate segments and retain those segments using the sleeve. Cool design but obvious tradeoffs, mainly the larger airgap like you said

This is correct, the carbon fiber sleeve is to prevent the rotor from flying apart. And you also can get rid of the iron bridges in the rotor. Without the sleeve these bridges would have been very thick to hold the rotor together and thus stealing too much flux from the magnets. When you calculate it the increased air-gap due to the sleeve reduces the flux less than the iron bridges would have done.

This with carbon fiber sleeve is not new however, we did a project around 2008 with such motors for a military vehicle prototype, however it did not enter into mass production. Also the Swedish company Elmo produced servo motors in the 80:s and 90:s with magnets held in place by winding Kevlar under tension instead of carbon-fiber. On of the large customers for the motors at the time was ABB Robotics.

So another potential connection between tesla and internal military knowledge/money, I mean skynet bringing high speed Internet to starving Africa is a bit of a thin Vale especially when the first true use case is war in Ukraine

15:11 It's comforting to see that the stator windings are held together with good old string

The star shaped design where the inner part of the rotor comes up to the surface in addition to the poles is so that it can partially act as a reluctance motor, this is presumably what that boost in power they mention is. Also, although the carbon does stop the rotor expanding, it is a bit more than that since it's literally the only thing holding the the rotor together, adhesives would not be strong enough and metals would introduce serious losses. I think they had a previous iteration where the pole laminations were actually part of the core laminations and that just could not have been nearly as good as this, although it did reduce the gap in the magnetic paths so it might have had higher torque.

I think american have rights to sue all n a z i & jaguar for immitate & push political agenda to sell their ev into usa market. Which trapped american civilians a n d only supports elitz c0mies

Fiber-wrapped rotors were researched extensively during the 1960s & 70s, where rotary-energy-storage was being developed. Such rotors were used in urban buses & vehicles, as inertial storage. Physical design actually shows that a rectangular-shaped rotor dies not have an ideal amount of energy storage. High-energy rotors use a "semi-cycloidal" shaping, as dependent on the strength of the fibrous windings. We looked at some of this while we were developing the Lunar-Rover motors. Fiberglass & Kevlar & Aramid fibers were used before carbon-fiber was available. The fibers actually do reduce the efficiency of the motor, since it is an airgap. However when the rotor expands, due to heating, the carbon can be shredded-off, and actualy "scrubs-to-fit" the stator. As such the motor can be self-adjusting to its specific thermal regimen. This technique is now used in aircraft turbines, as in C17, where the fan actually is made to grind-to-fit the containment stator. However, if the Tesla motor "overheats" beyond its design range, and if the carbon is shredded, and IF oxygen is available, that motor will actually combust and burn internally. Some other vendors actually suck-out the air inside the motor, to a semi-vacuum level. This improves the aerodynamic efficiency of the rotor. If rotor goes near-sonic velocity, in the gap, this creates major aerodynamic losses (shock waves), which will either heat the motor, or cause high-energy vibrations, which can also destroy the bearings. We ran into this in uranium-seperation equipment, at 60-to-90-thousand rpm. None of this technology is new.

none of these ideas are original. Everyone is just titillated by all the advertising muscle Musk has spent. Calnetix has been making high speed rotors like this for decades and the stators are nothing special at all. I'm surprised Musk didn't buy Yasa before Daimler Benz did. Just tells me he really isn't interested in innovation that much.

Mechanical engineer here. The main reason for the carbon sleeve under tension on the rotor so that it prevents any further elasticity of expansion due to centrifugal force and thermal expansion which can cause the outer diameter of the rotor to rub against the stator. Very sophisticated thinking by Tesla's engineers. This must be done using FEA analysis.

from someone who works in electrical trade sales: your history/physics lesson was fantastic, you gave an Intro to electric motors class in 5:30.

Wow....GREAT VIDEO! I never thought I'd understand this but the way you put it in all your simplicity, I'm a friggin' genius now. Haha!

Thank you for explaining this the way you did. This video was very well put together.

The outboard wheel always turns faster, it is traveling a longer distance in the same amount of time than the inner tire.

And the reason this comment by Carl was entered is that the spokesperson did not catch the error in saying "the inner wheel has to spin faster, and the differential allows this to happen"... The most basic geometry is not understood by the chosen spokesperson. Perhaps the average voter is in a similar level of incompetency in voting for public officials.

Ackermann Principle: The outer wheel must turn faster to travel the greater distance.

Railway engineer here... What I've learned is that other than some minor design tweaks in the rotor which are specific to their design philosophy, that the power control and design of any Tesla or any other EV powertrain is basically the same as we have been using on AC traction on the railway since the early to mid 90s.

Are u also wrapping the rotor?

I ll take teslas electric motor over anything you got in railways in terms of efficiency and power.

@@Matzes Of course you would because you haven't a clue about electric motors.

@@Matzes Railway motors are many times more powerful then Tesla's. Around 5000-7000 horsepower. Efficiency is about the same.

The reason a train doesn't accelerate fast is because the weight is bigger then a human can comprehend. Like thousands of times the weight of a Tesla car.

@@1superricko obviously I m talking relative to size.

This is the Tesla version of everyday astronaut

The stark difference being that everyday astronaut knows how rocket motors work. This is a very wrong description of how an induction motor works (completely ignoring the induction part). What was described here is a synchronous motor.

Your way of explaining the subject is so clear and easy to understand. If only my professor can explain the content like you do. Definitely subscribed.

"Content"??? Is everything CONTENT now?

Well done on the simplified break down. I have a preexisting knowledge on the subject and I felt like I gained a better understanding by watching your video. I’m in the process of creating learning materials for the company I work for and I wish I had your ability to make a subject comprehensible as demonstrated by this video.

Excellent presentation, my neurons kept up with you most of the time. Don’t ever remember a better motor presentation in all my 79 1/2 yrs ! God Bless &. Keep up the good work, I will definitely watch this again ! 👍👍👍👍👍 🇺🇸🦅

As an simple electrrician, I found this video very pleasant and well explained, cudo's to you ! If the schools would have such good explanation to physichs and other technical programs, the pupils would learn better and perhaps World could be a better place !

Thank you, this was so well explained, with just enough detail and language so that anybody can understand in a nice bite-sized portion. Love what Tesla is doing to evolve the electric vehicle and transportation as a whole.

Thank you. Very important topic. Not covered enough even by the best tesla channels. Listening now

I worked 38 years as a construction electrician, I worked 3 years as an Electric Motor winder, (I rebuilt electric motors) but there are still a lot of things I don't know of understand about Electric motors. I believe EVs are our future, I can say this even though I think we are not ready to shut down gas engines. The electric car has a lot going for it, if we get the batteries/charging worked out. Great video.

Steamship / Hydroelectric Powerplant USCG Engineer here.

If you think blackouts and brownouts are a big problem now, just wait ten years when millions of electric cars plug into The Grid at night to recharge. Better start fixing The Grid soon.

For anyone fascinated by this as much as me, I want to recommend the Lesics video on the Model 3 motor. It goes into incredible detail on how brilliantly Tesla arranged their magnets to maximize efficiency.

this

The outer wheel turns faster as it travels further than the inner wheel

At timecard 14:18 should be "the outer wheel has to turn faster."

Exactly, I wondered if someone caught this. Good!

well, when turning weight goes onto the outer wheel which makes the inner wheel slip, actually. in a perfectly symmetrical world, your argument would be the case, but factor in physics, it becomes counter intuive.

Fabuleous job! Love the simplicity in communication, particularly coming from such a heavy engineering subject.

Thank you for going above and beyond on this one. Value added, indeed.

Induction motors don't have permanent magnets in their rotors. A magnetic field happens in the rotor due to induced (hence "induction") currents in conductors in the rotor.

Tesla uses brushless DC motors which have permanent magnets in the rotor and use electronic switching to control the polarity/strength of the fields in the wound stator.

The commutator shown at 6:13 is a mechanical switch used to alter the field direction in a wound rotor. this would typically be used in smaller motors which have a pair of permanent magnets as a stator and are often seen in toys, also car starter motors. The commutated rotor can also be used with a wound stator, in the case of the universal motor, used in AC powered tools, like drills and skill saws.

Induction motors tend to be large and heavy (there are low powered exceptions, like fans and old record players), but very quiet and very long lasting. Universal motors produce a lot of power and are comparatively small, but make a lot of noise and require maintenance when the brushes wear out.

thank you for this comment, this guy's video is driving me crazy

Me not being engineer at this field just wonder: whe there were 3 contacts shown on the invertor? Dont they represent 3 phase of ac induction motor? Though i agree withagnets in the rotor:-)

@@yx2803 There are three phases to this motor, however, the frequency and amplitude of the three phases is controlled by some high speed switching circuitry Usually, devices called IGBTs are used in a chopped three phase H-bridge setup

Everyone saying "you explain it so simply" - not realizing how much is so wrong. To be fair, the Long Range does have both PM and induction motors, but the Plaid does not. I almost choked when he got to the commutator, as if the Plaid were a giant electric drill.

Awesome - I was hoping someone would make those points!

Fascinating! Thanks for talking this complicated subject.

best explanation of how an electric motor works that I've seen, thank you!

Plaid is a big win in power density mainly due to the higher RPMs it allows. This has 3 advantages in applications like the CyberTruck and Semi (both of which I'm expecting will use Plaid motors):

1. Lower weight -- the motor weight is reduced in inverse proportion to the increase in power density

2. Economy of materials -- the needed copper, aluminum, rare earths, etc scales in the same way

3. Reduced motor count -- CT and Semi will debut with 2 and 3 motors, not 4 and 4

Are you really expecting CyberTruck and Semi to use any motor? Like, do you think they are real, viable commercial products?

@@figadodeporco well the semi uses off the shelf plaid motors so he's right there

Great video! I really enjoyed it, i was actually curious about the engine. Great job 👏🏻, please do more about the engine

“Engine“??!… What engine did they talk about?… Or do you mean motor“? A motor runs on electricity and an ‘engine’ runs on fossil fuels, whether it be gasoline, diesel or natural gas, etc.

@@1-2_Flush_Water_Saver but people still say,” when you give it the gas” and more than a few people refer to pavement rollers as “ steamrollers “ that’s just the way people Communicate sometimes. Technically an accurate but really not a big deal

We leave the steam at the power plant these days.

…It was Tesla’s 166th birthday yesterday. _good timing_

The comments by the engineers are interesting and very detail.

Keep it up guys. Thanks!!

Great video. I enjoyed learning a lot from this. There were a couple points I think were perhaps a bit confused. The first one was, copper isn't what becomes magnetic in an electromagnet, it's the ferrous component (the nail in the image used) that has magnetism induced by the current flowing through the copper wires wrapped around it. The other being the outer wheel has to travel faster, not the inner wheel, but that appears to have been pointed out. I'm not an expert on magnetism, though, so if my point is in error, someone with more expertise, please correct my mistake.

You are mistaken on the first point actually, a copper coil on its own can act as a magnet. The nail acts as a core that amplifies the magnetic field. It's the reason coil guns work in the first place.

Actually yes, the copper is what becomes magnetic. The field is induced in the copper wire and coupled to the core. The core concentrates the magnetic field lines to a focused spot.

As answered before, the copper coil under electric current has a magnetic field of its own. What the iron alloy does, when becoming the core of the coil, is to multiply the magnetic flux with the ratio between the reluctance of the air and the reluctance of the iron alloy, for the same value of current passing through copper wire. Depending of the iron alloy, that ratio can be from hundreds to tens of thousands.

Another fun fact, RC brushless motors have used wrapped rotors for many years. Not sure who holds the patent or came up with the idea. Pretty sure it wasn’t Tesla though…

Time traveling engineer here.

You forgot to talk about the Flux capacitor.

Great vid.

Very interesting video - please let's have more of that !

At 14:20 though you have an error - th inner wheel do NOT turn faster than the outer - it's the other way around - right ?

When going around a corner, the OUTSIDE wheel goes faster... 14:18

It must travel further distance and keep up thus inside wheel is slower than the outside wheel.

Loved this episode too. Congrats 👏!

Ya you guy's are doing a great job, keep up the good work. I am learning more and more every time I get a chance to watch. Thank you.

Thud video was so well made and edited.

I was fascinated through the whole video. Even though I know a lot about this topic I still feel I learned a lot from this video.

Great movie guys, you guys did a lot of work and it came out great. (Below are [3] small corrections I saw)

*earths North Pole is magnetic south which is why the norther portion of a magnet points north (magnetic south

*Centripetal acceleration (force)

*outer wheel spins faster in a corner

where was the movie? was it the new Dr strange movie? i was listening to a guy ramble about an electric motor in the background.

i didn't hear a movie playing.

*AC induction motors don't contain permanent magnets.

If the inverter goes dead for some reason, the (very strong) motor could slow down the wheel as if you had suddenly stomped on the brake (but only for that wheel!). The explosive fuse could disconnect the motor in such a case, letting the wheel turn freely.

Oh my word & I thought improving electric motors, due to the already high level of efficiency compared to ICE was nearly as far as you could go & nowhere near as complex as ICE..... 🤦🏻

In the old days, a forced reversal was called "plugging". It resulted in hundreds of amperes of reversed current, the energy coming from the back-drive on the motor. In cars, this would result in an immediate skidding of the wheels, and uncontrolled spin-out deceleration. Usually the reversed rectifiers, SCRs, IGBTs just blow up.

I am thinking the explosive fuse has a lot more to do with the eventual failure of the IGBT or SCR and the likelihood that it becomes a dead short and a fire hazard due to the huge amount of Amperage available plus the high Voltage may arc and sustain the short circuit. Another factor is like you say that that one coil of the stator getting a huge amount of power and staying there would/could significantly and rapidly decrease the speed of the motor and wheels. There are several other ways to decouple the motor from the inverter without explosive fuses . I also wonder if it’s not maybe the DC bus supply to the inverter that’s being interrupted. 🤷♂️

@@brunonikodemski2420 "plugging" is now a perverse activity on certain websites 😂😅🤣

I do agee with Tony Bjorklund: Tesla has lots of pyrofuses in case something goes wrong.

Do to the cross-section, these "fuses" look more like contactors to short the motor's phases together...do you have a clearer picture of them?

Or do you know where can I easily find this bus-bar?

EXCELENT excellent demonstration, explanation & animation!!!

I already know how this works pretty much. I wanted to do a vid just like this. Time not on my side. You did an amazing job!

Good, simplified explanation; nice visuals.

14:17 The OUTER wheel spins faster, not the inner. I'm surprised this error wasn't spotted during even preproduction.

I was looking for this comment

With stronger magnets, you need less current on the stator to create a field for the rotor to follow, would be my guess.

Correct, which is why there are people ditching the old motor design and exploring the other design explained by Nicholas Tesla that is in theary more efficient and has the magnets spin not the coils, it has taken a long time for that design because of timing the coils with the magnets to get the best performance possible.

@@aaronpalmer7425 the magnets always spin you tard

Great job of pulling so many resources together to make a solid video!

That was great and am happy about how the community helps each other understand the truly awsome tec unfolding thanks

This episode is pretty amazing, seriously more tesla knowledge please 😅😇

14:19 No I believe it's the outer wheel that has to turn faster, as it has a greater distance to travel. Great video though. Very enjoyable watching this.

Good job and good use of existing content on CZcams.

So many Tesla channels nowadays but you guys are clear and to the point without being pretentious. Compliments from The Netherlands.

Excellent video. I have owned 8 Tesla's over the last 11 years but have never heard such a clear description of how the amazing motor works. One minor point, when you describe the reason for a differential, wouldn't it be the outside wheel that has to turn faster than the inside wheel, rather than the other way around?

Why have you owned 8 teslas in 11 years?

Wow, You killed this comprehensive cliff-note lesson on Electromagnetic induction motors. Outstanding !

Really? He incorrectly described an AC induction motor as having permanent magnets. It does not.

YERY interesting and well presented. Nice job and thank you.

That's actually amazing about the stronger magnets...not being held by anything!

I am an “ok” engineer with a regular job in a software company but learned a lot from this video. Wondering, if the real mechanical/electrical engineers working at Rivian/Ford would learn a hell lot more from this, and can dramatically increase the performance of their Cars, beating Tesla! Is that possible?

No, not likely, and not because they're bad engineers. The answer is simply Tesla is designed differently as a company. From what I've gathered, they seem to have taken the principles of Agile software design and applied them to an entire company, from design, through manufacturing, and every step in the process. Tesla is frequently making changes to their design, both small and large, all in the goal of improving everything with their vehicles.

Rivian is a much smaller manufacturer, and nowhere close to Tesla's scale, so there's a chance they can borrow some of Tesla's ideas, but I highly doubt they'll be able to take advantage of many of the largest Tesla innovations such as the custom motor wrapping, or 4680 cells as these are both completely new groundbreaking designs. These new designs require massive investments in either new product production plants or other major retoolings and I don't see Rivian being willing or able to change their production to make this happen.

Ford potentially has the size and engineering capabilities, but from what I've seen, the company culture and heirachy has severely ossified and is so inflexible that they wouldn't dream of trying these radical ideas. Furthermore much of their supplies come from third party suppliers so they don't have the same flexibility.

@@ChristopherGoggans Good insights!

@@ChristopherGoggans ...also Tesla is trying to get to Mars, there must be some high tech trickle down landing at the Tesla factory.

Seeing the Ford engineers beating the Tesla engineers would be an amazing show to watch. I'll bring the popcorn!

Other thing to remember is, there tend to be reasons why engineers weren't already using these cool ideas. I'd assume that Tesla's engineers had to solve a /lot/ of problems to make these ideas actually work in prototype, and then a whole other set of problems for practical mass production.

Engineers at other companies probably already understand these ideas in principle, but that's very different from making them actually useful in practice.

At 6:13, the animation is a Direct Current Motor using brushes. You also kept switching between single phase induction motors (four poles) and a three phase diagram (six stator magnet working off 3, 120 degree separation phases for 3*120=360 degrees. Which you show only occasionally. All of this confusion comes before the explanation of the T in Tesla Symbol.

In a 3 phase motor do you always have 6 poles on the stator and on the rotor? I was surprised when they showed 6 and 4 but I wasn't sure if that was intentional or just a mistake.

Thank you for explaining this so thoroughly. My one nitpick is that in this context non-integers should be rounded rather than truncated, so the Plaid required 152 N, the Model Y required 112 N, I3 was 94 N, and Mach E 82 N.

Nice. First time I have heard an explanation of the Tesla logo. Thank you!

What if I told you a brushless induction motor doesn't need permanent magnets?

Anyway, the motor design is innovative but not surprising, imagine the magnetic field lines created by the field windings and it makes more sense.

These motors aren't actually induction motors, they are Switched reluctance motors which is a kind of DC brushless design. Tesla did used to use induction motors but I think they switched over to using PMSR motors for all their cars now.

three phase induction motor is very different from permanent magnet motor

It was killing every other motor out there in the market until Lucid entered the chat 🤯

Well done. Another thing Sandy Munro mentioned as being different was the magnetism pattern surrounding the rotor wasn't staggered as would usually found in a typical electric motor...supposed to ensure smooth operation, though Sandy said he detected no jerky feeling while driving the plaid. Thanks.

Wouldn't the outer wheel spin faster going around a turn? at 18min

That is a stargate motor if I've ever seen one. Rather than stacking the magnets on the outside though they used the stargate configuration on the inside most like adding more magnetic flux to an already powerful magnetic.

the inner wheel will turn slower!!!

Thinking outside the box is a critical gift of genius at work.

yes ! a very nice video presentation at a pace i could learn. love the content so much

The Plaid was what I expected Tesla’s response to the Porsche Taycan to be. Porsche multiplied torque and increase top speed with a 2-speed transmission. Tesla did the same by doubling rear motors, increasing redline, and lowering gearing.

The taycan is a parlor trick. They have a pack system that can switch between 400v and 800v to fake faster charging. The car is two packs that each only handle 135kw. They only needed enough batteries to make two 400v packs because the car is inefficient, so cramming in batteries lets them advertise a longer range while they leave out the slower charge speeds due to inefficiency. They also had to use a transmission because they could not get a motor to spin fast enough. That transmission will likely fail early. Porsche keeps claiming the current dash transmission errors are purely software bugs, but there is no way to know, legacy companies will always try to update cars in negative ways for the consumer to push component failures beyond the warranty period. People are gambling on if the transmission failures are hardware issues with a software coverup or just bad software that in theory can be fixed with an update.

....transmission is antiquated. hub motors are the future and the present

@@Blox117 Hub motors have very high unsprung weight, the enemy of good suspension engineering. For automotive use, hub motors are a bad idea. A little gear reduction and a haftshaft work just fine and keep the motor well away from vibration, water, dirt, and salt. It also means the cooling lines and high amp wires aren't flexing all the time which could be a real problem over time. The reason many racing cars use inboard disc brakes is to reduce unsprung weight.

Thanks for making this video, I think everyone needs to know the basics behind why electric cars are so good and why teslas are brilliant! IPM synRM plus the iron core rotator magnetic gap and the carbon fiber wrap (which doesn’t interfere with the magnetic field) is just plain brilliant!

Lolzzzzzz

yes but I wonder if the thermal envelop of the epoxy isn't an issue. Carbon fiber really need a new high temps binding agent !

Excellent content, thanks for the work explaining this. Superb!

@14:19 Slower not faster, the inner wheel must turn slower and the wheel on the outside must turn faster, because it has to travel a longer distance. Nice video! Thanks for share your knoledge.

In general, larger motors are more efficient, the inverse for transistor switching where smaller is better.

The new frontier is driven by smart high-speed semiconductors that end up to very high wattage semi-conductors with very specific chemistry & reaction characteristics.

Add to that the new permanent magnet alloys with higher curie points & add in new induction motor designs made possible by computers as high speed intelligent relays, & it’s hard to keep up with you don’t have a magnetic personality or are not in the field.

No, the OUTER wheel has to turn faster when rounding a corner.

Nice coverage. Thanks!

That was very satisfying for a techie like me. Thanks.

I believe the 'explosive fuse' is detonated when there's a airbag deployment... therefore, immediately disconnecting power to the motors.

Not sure about the "floating caps" but as with transformers the reason the core is laminated is likely to better carry magnetic flux from the primary to the secondary windings and to reduce energy robbing "eddy" currents circulating within the iron core itself. These currents cause heating and energy losses within the core. Those floating caps are VERY interesting though.....hmm

The floating caps acts like a lens focusing the magnetic flux concentrated into one spot.

@@kazedcat it also breaks specific magnetic paths through the motor for the "reluctance" aspect of the motor design (it's not just a permanent magnet motor)

Fascinating and helpful. Thank you! ! !

Induction motors DO NOT use permanent magnets! Tesla does Not use induction motors in their cars. I believe it is a SynRM motor (Synchronous reluctance motors).

Correct, also, Tesla Motors used an induction motor in their first car, the model S, the model 3 uses IPMSRM in the rear and an induction motor in the front. :)

When you hear idiots like Gordon Johnson who loves to state that Tesla has no competitive advantage Technologically or Materially it just puts things into context.

Only 3-4 years ago Tesla was at 100k units a year and ramping up the the Model 3. Now we're at 1.5 million and the Model 3 and Y are two of the most popular Cars in the world. And that's not just for EV's that includes ICE with a clear lead in the US and Europe.

I don't know whether Tesla can get to 20 million units by 2030 but even if they only got to 10, 12 or 15 million is anyone going to really be calling it a failure?

Afterall even at 10million units per year which is where Toyota and VW

were before COVID neither company came close to Tesla's gross margin! So 10 million units at an average of 30% plus gross margin would mean a gross profit of 180 billion?

Not bad considering the experts have been writing off Tesla since it was founded.

Poor old Gordon is beyond an Idiot. I think they only put him on shows these days is to give us all a laugh. Every court needs a Fool.

Great content, Money is worthless until you put it to work.... I made my 1st million investing in Crypto. Making money is the plan and with investing in crypto your plans can be fulfilled

I agree with you... I had a senior colleague at work who was doing well but never had an investment. Unfortunately he lost his job and went from living a comfortable life to hardship. There would had been something to fall back on if he had an investment

@Alex P. Pugh

I met with him at Washington DC, in a conference meeting, after he has finished pitching, was opportuned to meet with him and started investing

Wow, you trade with Mr Jesse also??. he is the best and his strategies works like magic. I have been making over 300% of my investment weekly, pioneered by Mr Jesse.

Please how do i get in touch with Mr Jesse ? I would love to work with him.

Thanks a lot. I'll most definitely ensure to do that 🙏

Nice work, content, and information.

Very insightful video! Well done guys!

This is an excellent video - thank you for the layman explanation on how the induction motor works and then going into the specifics of the Plaid motor differences, as all the points come across really well. I walked away with a much better understanding of the motor basics and it helped to understand some of the details in Sandy Monroe's video that either weren't explained or were glossed over a bit due to assuming the viewer had a level of understanding that might not have been there.

Very informative I enjoyed watching your video always wondered how it worked.

Thank you so much for this video I've always wanted to watch 🙏

Beautiful! ❤ I’m pretty sure that fuse is if that epoxy breaks and prevents a rotor blowout accident.

great video… succinct and yet very informative. no words wasted.

WOW! This is a wealth of information. Thank you for sharing.

Let's never forget the immortal lyrics

"F'in magnets, how do they work"

I remember when I was a little kid. We had these itty-bitty Hotwheels called "Sizzlers." I think the stators were permanent magnets and the rotors were copper-wound electro-magnets.

Impressive detail AND explanations! 👍🏻

WOW man, you hit a Super Grand Slam in this video!!!!!! Sup;er Clear and easy explanation covering all the details of why the Plaid is the strongest and most advanced electric motor!! You were even more clear than Munro's video, and that was a super video too!!!!! Keep on your good track and work!!!!!!!

14:17 ... said that backwards ... the outer wheel has to travel more distance, so the OUTER wheel has to spin faster , but we follow

Excellent I appreciate the detail and the emphasis on manufacturing simplicity now if only Tesla can get the fit and finish portion of manufacturing to a pristine level

The info is very good ans only manor thing in the description of a turn is that the inside wheel would turn slower and the outside wheel would turn faster.

Other than that I like the video very much!

Keep up the research and production of more video’s!

When you were talking about, brushless motors you actually had a video of a brushed DC motor in there. Haha I was like why is he showing that, he's going to confuse people. But overall really good video 6:18btw

That Was Very informative,more lit that would be great to here!, thanks

Well done Tesla Space team!

I'm very sure they are neodymium magnets. With a carbon fibre wrap around the iron core to hold it all together. Very clever design.