Video není dostupné.

Omlouváme se.

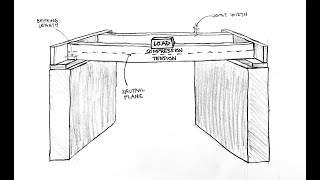

Wood Reinforcement - Notched Beam

Vložit

- čas přidán 22. 09. 2014

- ✅ SUBSCRIBE ! rebrand.ly/Mtcs... (Thanks !!)

This video showcases the difference between a reinforced and a non reinforced notched beam. MTC Solutions aims to provide reinforcing design procedures for wood and mass timber elements using self-tapping fully threaded screws. Read our White Paper for more information:

👉 mtcsolutions.c...

Don’t forget to check our website for more information :

👉 mtcsolutions.com/

Let's Connect!

✅ Linkedin: / myticon-timber-connectors

✅ Instagram: / mtcsolutionsinc

✅ Twitter: / mtcsolutions

✅ Facebook: / mtcsolutionsinc

Super video, a short in 2014 long before shorts were a thing! bravo. straight to the point and helpful

@minikodtlivov: Thank you for commenting. Notches such as a notch in timber beams used for mass timber construction are not typically dimensioned just to have a notch. It is detailed to accommodate certain building requirements or, virtual notch considerations are a detail requiring structural consideration. The purpose of reinforcing technology in notches such as demonstrated in our video is engineered so that Mass Timber Beams with notches or virtual notches can be used instead of steel. By doing this we are now able to use a substantially more sustainable structural component and contribute meaningfully to the sustainable building idea.

Interesting video. ¡Gracias por compartir!

Thanks, so useful 😊👍🏻

Very interresting.

In old fashioned timber framing , the ends had a long easy curve instead of that large rabbet cut /notch. It is harder for a crack to propagate through a curve than at the apex of right angle.

Thank you Pocketfarmer1 for this comment. This is correct. Back in the days reinforcing technology such as long full thread self tapping wood screws did not exists. Through the understanding of historic mechanics and stress flow master builders rounded the corners to allow stress to change more gradually rather than with a sharp spike at the origin of the notch. This technology works still today, we have tested that a few years back. The issue there for engineered large scale structures is however that we are then again dealing with the uncertainty of wood and larger variations due to natural things like knots and slop of grain irregularities. This, in todays environment is a challenge to proof reliably from an engineering point of view and it also increases machine time if one looks and considers CNC machine cutting. The better choice today, with a reliable outcome is to apply reinforcing screws with long full threads because we can control the properties and performance of our reinforcing efforts.

@@maxclosen7457 given what you you have said , mightn’t a combination of the two techniques be stronger. Where a long curve well beyond the shelf plate ends , then reinforcing screw at some optimal point through the full thickness?

@@Pocketfarmer1 Thank you for the question around this topic. A combination of both technologies will not work, it will not make the connection two times stronger. One of the reasons why this can not work is the different stiffness of the reinforcing methods. The reinforcing screw option is much stiffer than the wood fiber perpendicular to grain and will therefore attract the load first. Only after the reinforcing screws fail the rounded corner option will kick in. Since the load, due to the reinforcing screws, will have accumulated to a level exceeding the wood fiber strength, you will be seeing an immediate failure of the notch even with the rounding.

Will curving the notch make the beam stronger than installing the full thread screws, and is there a formula for the size of the radius?

@@huejanus5505 From our experience in the testing smoothing the corner only has some small impact on the notch strength. It is much weaker than a full thread wood screw reinforcement and still subject to randomness caused by slop of grain and regular wood irregularities. For applications in structural settings we would recommend to go with a screw reinforcement. I myself am not aware of a formula. If you are interested in this you may reach out to the Timber Framers Guild in the USA, there are some good folks there with a lot of historical knowledge.

Can it be screwed from the bottom Instead? Being that the bottom is all anyone can get to in a basement setting

Hello Jesse, good question, thank you. The Answer is yes, you can install the reinforcing screw from the bottom up, it is the same procedure overall. Contact a local design professional to help you determining the embedding required below and above the notch.

Great video, thank you. Do you know of wood tend to fail on the darker grain line or between the darker grain lines? You seem like a guy that would know. I suppose I could do a test to figure this one out. Thanks!

on a pine board the darker grain lines are stronger/denser, it’s noticeable on a old deck or something you’ll feel the ridges from where the lighter parts have shrunk. I’m not sure what you mean about your question though

@@james3522 It would also make sense that knots are very hard and very dark.

Notched beams usually placed to take a vertical load.

Hello Bigal25938, Notched beams can be applied in all sorts of scenarios. Notches may be found in floor beams, roof beams or girder beams for instance.

I don't see too much meaning of this video, since notch which is at the end of the beam is always over dimensioned in comparson to the length and load of the beam in real case. This jack is maybe 16 ton. For this loads you use metal H beam and some special

load calculations....But OK, If someone find himself in special occasion with limited sources this is good reminder.....

What kind of screw is that?

Hello Jose, the broken joint is pulled back together using a washer head screw. The reinforcement is achieved through a full thread wood screw similar to a rebar in concrete.

@@maxclosen7457 thank you do you have a model number or name for the screw

Beam notches are only allowed up to 1/3 the height of the beam for this very reason.

Hi Joe, it is correct that design codes limit notches for this reason. However, there are things like "accidental notches" or penetrations and opening in bending members that sometimes are required to accommodate services. In those cases, as an emergency repair or to allow openings in bending members the reinforcing possibility bis a great tool and problem solver

@@maxclosen7457 I agree.

Hello Amateurism, the splitting of the wood is perpendicular to the grain direction. This is the weakest strength property of wood. The dark "lines" you are descripting are caused late wood typically. I am not aware of late wood being a major factor in splitting perpendicular to grain.