Cavitation in pump . Centrifugal pump. How it works. Types of pumps Types of impeller

Vložit

- čas přidán 9. 09. 2024

- #cavitation #impeller #centrifugalpump

Air flow rwgular

What is a centrifugal pump and How it works.

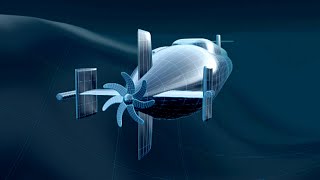

Centrifugal pumps are used to transport fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. The rotational energy typically comes from an engine or electric motor. They are sub-class of dynamic axisymmetric work-absorbing turbo machinery. The fluid enters the pump impeller along or near to the rotating axis and is accelerated by the impeller, flowing radially outward into a diffuser or volute chamber, from which it exits.

What are the common uses of centrifugal pump?

Common uses of centrifugal pump include water, sewage, agriculture, petroleum and petrochemical pumping.

Centrifugal pumps are often chosen for their high flow rate capabilities, mixing potential, as well as their relatively simple engineering.

How does a centrifugal pump works?

Like most pumps, a centrifugal pump converts rotational energy, often from a motor, to energy in a moving fluid. A portion of the energy goes into kinetic energy of the fluid.

Fluid enters axially through eye of the casing, is caught up in the impeller blades and is whirled tangentially and radially outward until it leaves through all circumferential parts of the impeller into the diffuser parts of the casing. The fluid gains both velocity and pressure while passing through impeller. The doughnut-shaped diffuser, or scroll, section of the casing decelerate the flow and further increase the pressure.

What is priming of centrifugal pump?

The process of filling the pump with liquid is called priming. All centrifugal pumps require liquid in the liquid casing to prime. If the pump casing becomes filled with vapors or gases, the pump impeller becomes gas-bound and incapable of pumping. To ensure that a centrifugal pump remains prim and does not become gas-bound, most centrifugal pumps are located below the level of the source from which the pump is to take its suction. The same effect can be gain by supplying liquid to the pump suction under pressure supplied by another pump placed in the suction line.

What is cavitation in centrifugal pumps?

Cavitation occurs when the liquid in a pump turns to a vapor at low pressure. It occurs because there is not enough pressure at the suction end of the pump, or insufficient Net Positive Suction Head available. When cavitation takes place, air bubbles are created at low pressure. These bubbles upon sudden collapsing causing damages in the related parts like impeller and pump housing.

What are the types impeller of centrifugal pumps?

Well Explained in short amount of time! 👍

Glad you like it

Keep it up sir

Thank you.

we will try

👌

thanks