WHAT is this, and WHY do you want it under your STUCCO?

Vložit

- čas přidán 5. 09. 2024

- If you think about stucco, its a difficult assembly.. Its basically a sidewalk on the side of your house.. Stucco gets a bad rap because of all of the failures it can cause - Matt shows how we can make the stucco last the life of the house without problems!

Follow along with Luke -

/ mezgerhomes

mezgerhomes.com

Delta Dry and Lath - www.dorken.com...

Follow Matt on Instagram! / risingerbuild

or Twitter / mattrisinger

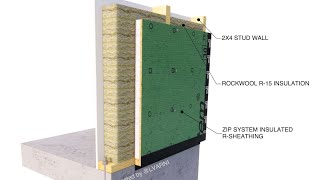

Huge thanks to our Show sponsors Polywall, Huber, Dorken Delta, Prosoco, Rockwool & Viewrail for helping to make these videos possible! These are all trusted companies that Matt has worked with for years and trusts their products in the homes he builds. We would highly encourage you to check out their websites for more info.

www.Poly-Wall.com

www.Dorken.com

www.Huberwood.com

www.Prosoco.com

www.Viewrail.com

www.Rockwool.com

Whoa! As a 25 year vet in Missouri, installing both Stucco wire lath and Efis (Exterior, insulation,finishing, system.) foam.

This product looks great! No more wire? No more paper!?

This looks amazing.

I'm still an Efis fan though.

Gold coat with mesh over zip system, then 1 1/2 foam over exterior. Sanded, chalklined, and groves cut.

The base coat is much stronger along with better R value.

The weather expansion is always breathing. Not many cracks and if so, very small with proper insulation. In Mo, weather here is much different in terms of expansion. We also use 5/8ths durarock sheets. 4x8. Very strong and great for golf courses where balls are hitting homes😂.

Great content. Loved seeing the boys using a "Go Devil" or "Cheater" on the wall. Great way to put mud on the wall vs a hawk and trowel.

Where I live most stucco homes are painted so 99.9% of the water never gets to the stucco. The double D paper creates a drainage plane when the top layer swells when the wet stucco is applied and then shrinks during the drying period creating a gap between the layers. An extra layer of 15lb felt over the plywood sheathing creates a durable assembly. Many of the problems in modern construction are due to the failure of OSB and Tyvek when designers want reservoir cladding. Just say no!

Builders beware, Im watching Matt and learning what is really needed in a great house build.

disney like me Also an awesome way to double your total costs

This video gave me PTSD - my house was built in 1947 and besides the exterior, they used stucco on the *interior* walls of the house. I've had two different tradesmen over the years say "I've never seen a wall like this before" - much like the Ghostbusters joke "They don't build 'em like this anymore" "They *never* built them like this!" :-)

The method they used on the interior walls was to put up a tar paper against the studs - essentially a 1/4 inch thick asphalt with a chicken wire mesh inside. Then they put up more chicken wire mesh and used that as the lathe to hold the stucco together. This does build some very solid walls and they have a nice hand-plastered feel, though nothing is straight or square in our house.

There are two downsides: Anytime you try to cut into the wall you're cutting through two layers of wire and they'll dull up a zip tool bit in a hurry. If you use a Sawzall, not only will it wear down the teeth but if the wire catches in a saw tooth it'll vibrate the entire wall, loosening or even cracking the stucco. The other issue is a modern-day problem: the layers of wire mesh in the walls eat up radio waves like nobody's business. I needed to put up four Wi-Fi hotspots to get decent coverage in a 1500 square foot house and many mobile phones lose connections once you step inside. Just imagine: every interior wall has four layers of wire mesh (two on each side) and each room is essentially a Faraday Cage just soaking up any radio signals...

might be healthier because of the lack of radio... it causes an increase in dna damage, especially over decades.

Wow! That's definitely overkill. They did used to make wire lath plaster walls in bathrooms, shower walls and other wet areas back in the day but it was normally a single layer or lath. In my 1950 house, the bottom 4 ft of the bathrooms and 1 shower were about 1" thick plaster, not fun to demo. The rest of the house was normal plaster over 3/8" rocklath. One ceiling was metal lath, and about 1.5" thick! The demolition guys hated gutting that room!

We just need more builders like you!! I do remodels and find water dmg in 99% of the jobs

that looks suspiciously like a foundation mat (mandatory here in the nordics) and ye olde stucco mesh just glued together.

I would love to see an episode on roof venting in high velocity hurricane zones, namely O'Hagan roof vents.

I loved this episode btw. My work encountered a bad stucco job a few years back.

Me too

Matt, love your channel and appreciate what you bring to the masses. After having had build three houses (Maryland, Tennessee and SW Florida)... I can confirm MOST builders (and their contractors) use the most economical and QUICKEST way to build homes. I was so shocked on your OSB vs ZIP the minimal cost difference (labor is about the same..so builders should not be asking uch more than the approximate upgrade for the materials).

I did a search on your channel for a product that I used to insulate my garage and was considering for my next SW Florida CMU 1500 sq ft (under air) home... InsoFast. I did not see any review on it. My thought was to use it in lieu of a ICF home. It has plastic studs 16 on center (plastic is a thermal break, no conductance and cuts framing cost out since studs are integral).

Also, I remember seeing a Oak Ridge Laboratory (I think) test using a spray bedliner material (Rhino) on CMU block for hurricane protection. I imagine it would also be a great vapor/air barrier. Mythbusters even did an episode where it was "bomb/blast proof :0 ). What's your thoughts on spraying the outside of a CMU home with bedliner and then applying a 2 inch InsoFast panel on outside and maybe 1 inch insofast in on inside of new home?

Sealed attic with spray foam and metal roof.

Thanks !

Awesome video .... Love new products and new methods. Thanks for sharing Matt.

I see the Zip wall in the back that has the fluid applied sealer on the seams and nail holes. Now when you apply the Delta Dry and Lath they are putting many more nail holes and staples into the Zip wall. Doesn't this defeat all the care that was taken to seal the holes in the first place?

That's what I'm curious about

No. They penetrate the zip but have an air gap in front of them which means there is no pressure to force in water AND it means the cavity will drain & dry! This leads to excellent durability for the house

What about air seal?

@@buildshow Just curious though, if that is the case then why put the liquid flashing on any of the nail heads that are going to be in the cavity in the first place?

@@musicims Because it gives an air seal that the staples ruin like Malfunction142a stated.

Great video Matt, thanks. Using stucco as cladding is great as long as you follow best installation instructions for any application. Is no different with any other product you install on your house. Lack of education, cutting corners or laziness is what creates problems. BTW, I didn't see reinforcing of the corners on windows and doors, or maybe my eyes miss it.

Great video, no idea if our last house we had for 11 years that is now 20 years old, or our current one has this stuff, and we had stucco on both. if not, not much I can do. So once again, while I love this channel, it also shows any house I own will probably fall apart

Thanks again

Not a builder....question on the rain-screens though. In a climate like Nebraska where we have basements, how do you transition the rain-screen behind your siding or stucco to the rain-screen around your foundation walls? Also, whats a good product to dress up the foundation walls if you install a rain-screen? Wish I was in the construction world...I can't get enough of it. Stuck in a sales job to pay the bills.

You don't, the two drainage cavities are required to remain separate. You also cannot ventilate the cavity via the soffit which ventilates an unheated attic. The idea is to allow air to enter at the bottom of the rain screen to carry out any residual moisture that gains access into the cavity via evaporation. Larger quantities of water entering the cavity are expected to drain out via gravity above grade level and flow away from the foundation. Drainage mat on the foundation wall is to reduce the possibility of hydrostatic water pressure forcing water through the foundation wall.

So how would you transition between the two?

@@acoenen2804 it would vary depending upon the thickness and type of wall systems being utilized, but one common means is to terminate the wall system above with a metal drip flashing before changing over to the system being applied to the foundation wall.

If only news reporting was so informative.

You've detailed the zip with liquid flash for the penetration, but what about the nail and fasteners used to hold the new product up?

They penetrate the zip but have an air gap in front of them which means there is no pressure to force in water AND it means the cavity will drain & dry!

Matt Risinger Ahh.... gotcha. Any concern with breaking the zip air barrier?

Scott from Essential Craftsman sent me.....great channel, subbed.

Bomber content Matt!

Would you use this delta dry dimpled barrier on an ICF house?

Straight onto the foam?

Wrap foam first then delta dry?

*making plans to retire on Texas coast.

5:25 common, give these guys a skytrack or anything , wow poor worker, shoveling mud all day like this... I live in Quebec, we do stupid shit that are hard for our body but in 10 years I've never seen a bricklayer shovel up the mud like this (we don't have much stucco here). The amount of money their boss is probly making should allow to buy something to prevent back pain. Security at work is as important as building science I believe. btw I'm a HVAC guy who goes on a lot of new homes construction.

R there issues with all the new nail holes being put itnto the zip system??

Hey Matt, I am learning allot about building, keep up the great series. As for the Delta "dimples" in this video, I understand the airing between cement and ZIP, but, dont you think the space will harbor insects, etc?

Phoenix Az- Yer channel is top notch! I have a ‘70s block home, flat roof and old ugly rough stucco. Do have a “Best practice” video/advice on converting to sand smooth stucco finish?

When they hang it, they just put thousands of holes in the Zip system with the nails/staples that they can't/won't seal. The zip system is useless at that point.

Erich I also question that. Is the zip system that self sealing, especially with that many staples?

On a previous video I think he did a show on how they made sure to seal the zip system on the seams and nails that used to hang the zip system. However hangin this system will add thousands of holes that they don't seal. Seems to invalidate the zip system. The guy even says this at 1:39 that hanging the system introduces thousands of staple holes into the zip system! Why bother with a zip system then. it is not sealed in anyway after this product.

@@erichb1 The Huber rep here told me that you can look at it both ways. Does it cost more to install a WRB or just install the zip system?

Zip panels are more airtight and watertight than your traditional stuff like Tyvek. Also makes your house watertight as soon as sheathing goes up, so you can go right into electrical without inspectors complaining. So what my rep tells me is, yeah you'll punch a lot of holes into the system, but we're talking about a negligible amount of leakage in 95% of homes. For a comparable WRB you need to opt for a peel and stick, like a Henry's system because Tyvek is still relatively leaky.

Either way, you need a WRB behind the dimple mat. Either Grade D building paper like jumbotex, Tyvek, etc. So there's some benefits of using the zip system.

I'll say this though, I don't like stucco over fiberglass mesh. We did a mock up for a client with this very dimple mat by Boral, the stucco did not like impact when we demoed the mock up. Metal lath was flat out more durable when we demoed it. Lets just say once we broke a large enough piece off we could almost yank large chunks out by hand compared to metal lath. Not a fan of fiberglass mesh laths for exterior stucco. Metal lath and fiber in stucco mix is the way to go for longevity.

I've had two corporate moves in my career with buyout options. Only rule, if the house has stucco they wont touch it you on your own. One of my neighbors just had a very costly stucco remediation on a 10 year old house. Stucco = plague

Matt if you’re framing a new home. Would it work to use traditional plywood on the exterior framing.

Waterproof the plywood then go over the plywood with an insulated zip system. The environment is

Coastal Maine.

I you want a Plywood shear wall I would use a Wrb like Delta Vent SA over to of the Plywood then use Rockwool then an air gap and your cladding.

That would be kinda pointless zip is basically just plywood with insulation on the back side of it you can get zip up to I think 2 1/2" thick

The inside layer of plywood would just be overkill and a waste of money only reason for doing it is to keep the zip system from bowing in if nailed to tight

The PhD structural engineer across the street from me nearly tore his expensive house down and rebuilt it, 20 years ago. (I have lived here more than 30 years, now.) He sheer-walled his garage... and perhaps his entire house(?), with plywood, especially considering that he has a heavy mass atop a flimsy cavity... a garage. In Long Beach, we live near the Newport Inglewood fault and everyone knows that earthquakes wreak serious damage in California... and sheerwalls are a worthwhile countermeasure. My garage has its own roof and for that I am grateful.

should you use this on an ICF house?

this is great, but I think it's really important to emphasize that stucco is not parging, and parging is not stucco; entirely different philosophies that a lot of times get mixed up and cause issues

So which in your opinion is better…this product or the zip systems rain screen?

Can the dimple delta material also be applied as one layer over conventional wooden sheathing and before brick, rock or concrete stucco?

Matt, I was always curious why they dont use fiberglass on exterior of houses like they do on boats? I bought a house few years back that had a shed that was fiberglassed thinly over the entire exterior its approx 52yrs old now based on permit with no water rot. It looks like he tacked the cloth to the side with roof nails, then stuck small patches of fiberglass over the nails before painting it.

Hmmmm. Interesting thought

It would be cool to see a video about FRP cladding and how it's used. I know it's a thing in commercial construction, don't know why it doesn't show up in residential so much. Cost maybe?

its a composite material. the upcharging, special tools and forms, and resin make it expensive nowadays. you might have an asbestos panel shed that looks like fiberglass if its that old...

@@Baigle1 not asbestos, its fiberglass, because part of it is exposed when they wrapped the cloth over the top of the walls. The way it was done is the sheeted the walls with plywood, then nailed cloth matt to the exterior walls, then painted the epoxy on the cloth, then over the nails they epoxy small squares over them and blended the epoxy. The cloth above the walls is still in weaved cloth pattern

I've seen some sheds done up like that around the rain forest on Vancouver Island. (Lots of boaters there.) I also had a truck topper coated with the spray-on stuff. I also repaired some 100-year-old carved trim by painting the resin thinned with acetone directly on the wood about 20 years ago, and it's holding up, and I've seen some wood outdoor futniture painted with the resin in southern Ontario. (Lots of boaters there as well. Leave some areas uncovered on the bottom for drying if you try this.) It might be too rigid to cover something the size of a large house, though.

I like studying about anything related to stucco. So I have two questions. 1) If you are using the Roxul board over the shear wall siding (be it plywood or other type) how do you get this new product attached to it? Roadenhouse washers? 2) Is this product alkaline resistant enough so that it could be used with ecologically responsible lime plasters? I ask because I currently use expanded metal lath made from stainless which is quite expensive. The plaster membrane ends up being at least 2 inches thick with four coats. Thanks.

Better question is why would you ever stucco your house when there are so many better performing/looking options.

Beauty is in the eye of the beholder, but here in the Southwest 90 percent of our houses are stucco. I think it looks great here, but there are a few snowbirds who just can't leave their Midwest and East coast siding or cladding behind. There several subdivisions that cater to those folks.

Matt H Fireproof and maintains a more stable temperature in very hot climates with a classic Spanish style look it it. All ideal factors for the Southwest.

@@matthewhall5571 Rock is fireproof. It also looks better and has a better chance of stopping bullets. ;)

I wonder how this would work on a straw bale house build.

With all those staples, the Zip system is no longer air sealed or water tight. I would maybe glue on Pressure Treated 1x3 studs or strips of PT plywood to the outside of the zip system every 16 inches on center and nail a cladding into those instead of nailing into the sheeting itself. The studs would provide a nice airspace as well. Exactly like rainscreen battens under siding.

Great video Matt, thanks... Question, anyone ever use Durrock with a drainable type of Tyvek under as a base system, with the drainage mesh, before the final coats?

Matt,

Great video. Any concerns using an outboard vapor barrier like this in colder climates? The air gap looks small(ish) and provisions for ventilation ("ventilated rainscreen") at the base of wall, sill, head and top of wall look limited. I would be concerned about the drying capacity of this wall. Would a vapor permeable/vapor open drainage plane/lath combo make more sense (again, for a colder climate)?

that sort of nipple mat is normally used in here in the nordics as foundation water barrier technically its not watertight and it doesn't need to be because it's main function is to prevent excess moisture but not all of it and it has that weather barrier beneath it that allows any condensed water to drip down.

Great product that *can be made from recycled plastics !*

The bottom up installation appears to indicate that rather than keeping and water in the air gap to run to the bottom, they are catching and driving it back out towards the stucco. I can see Pros and Cons of both methods. Is this the way the manufacturer has advised?

Matt, can this product used over the Zip-R system?

not here in Saskatchewan Canada. they all do it the old way.

The old way worked when you were putting the tar paper over Douglas Fir, which most Sask Houses were covered with until the 70's. That stuff was pretty rot resistant. SOME of the new builds spray a waterproofing coat over the stucco, though. 70% of our new builds are disposable housing in everything else, so why put anything good on the outside?

Aren't you creating leaks in the zip system when you nail/staple in the stucco polywall?

i wonder if this would work for brick walls in the northeast / mid-atlantic region

Love this channel and all the products you showcase. I like the explanations of the products and sample installations.

However, I would never buy a stucco home. Period.

I've been to Houston, San Antonio, and Dallas/Ft. Worth, if not yet Austin. They each have their own climate differences from each other, but they're all a lot closer to each other, weather- and temperature-wise, than what the Seattle area faces. Do you know of a good channel like your own that discusses best building practices for our cooler, soggier PNW climate?

One observation, shooting in those nails and staples into the tightly sealed Zip system seems rather counter productive. Surely there's a better way to attach it without continually perforating the key moisture control system it sits on?

Somebody needs to invent a fastener that's waterproof. I thought that might be the orange-plastic-assisted nails&staples ("cap nails") mandated for use, in my recent re-roofing. I caught my roofer in violation, early when he was fastening the GAF TigerPaw paper (in lieu of obsolete tarred felt paper) and made him add another layer of TigerPaw, using the orange-capped fastener required by TigerPaw's engineering spec; and that requirement was printed all over the jobsite paper! Recently Matt performed a leak test, and showed this fastener was not the panacea I was expecting it to be. (I wish I could post a picture.)

As others have asked, thanks for that, I would put a sealer on top of the stucco with fire and heat reduction capabilities in it. Would be a two fold affect in the south where we live. I’m in Jacksonville Florida.

Caulk and Block.. and then poke with thousands of staples? The hell, dude?

Matt, I am in the process stuccoing my new addition and you convinced me to use a dimple mat rainscreen. I need help figuring out how to terminate the rainscreen at recessed windows. Do I use a casement bead? I can’t find any install instructions on the recessed windows. Help!

Peter, I have a similar issue- recessed windows. I have 2 inches of foam board as well. I will have to remove the foam around the window, make a wood frame around the window so the product can be nailed properly. Then I will be able to install my thin brick. Hope this helps.

It seems odd, it's the year 2019 I've been told; yet how is it that the art of not rotting a wooden house in practice hasn't Been implemented on most structures?

Because old buildings had lots of heat and air loss to dry them out. New codes mean less loss and less drying potential. If it can’t dry it’s gonna die.

Matt Risinger

The largest problems that I see All Over the country comes from the adoption of OSB! Your rhyme is cute; but you, as a builder, are doing a disservice using OSB.

Bear Buster pretty much everyone uses osb and it’s been around for decades. It does work.

patty109109

I know OSB is widely used but the only valid justification for its use is it is cheap. I have seen numerous relatively new places falling with what would have had minor problems if different material was used.

@@bearbuster157 the same could be said and was for plywood but the industry has move away from using concrete form boards on the diagonal many years ago. In the end if you are not properly protecting your sheathing from water it will rot regardless of its form.

Is there an equivalent version for more traditional, layered siding, such as Hardi-Board, actual wood siding, or maybe even aluminum siding?

Jeeez, then they pound a ton of nail holes to affix the dimple/synthetic liner into the Zip, creating holes for air to travel through. WTF ?

Plugged over with render i guess

Does this process work on cinder block walls? If not do you recommend a installation method for cinder block walls? Thank you

its getting stapled down with allot of looseness inthe center ? bubbles? 1;17 2;05 2;42 will finish be full of waves /bumps

how do you treat the coners of house with this product ??

Maybe a stupid question... but why would you want stucco on your house? I don't see the benefits of having a "water sponge" on your house.

If installed properly it is very durable, no-maintenance, fire resistant, and can look quite good. As a result it is very commonly used in commercial, despite being more expensive than many other assemblies. Additionally stucco is the same thing as many stone or tile assemblies (which is why some people call that style "lumpy stucco").

I'd much rather have Galvalume and avoid the fuss but some cities require a percentage of the front facade to be brick or stucco.

20 years in a stucco house--rock solid.

In a word: Durability

How does this compare to traditional stucco base / prep products for costs?

wouldn't it also be a good idea to add hydrophobic spray as a top coat over the paint layer ?

Why instead putting two layers to avoid humidity/water passes through the wall, you just don't water seal the stucco?

Really curious whether this level is needed in Arizona. Arizona is primarily stucco finishes, with minimal rain.

One way or another, get a radiant barrier behind stucco construction, WITH AIR GAP, and with some air flow pathway so convection updraft can lose the hot air outside the structure. I live in coastal SoCal... a few miles inland from the ocean, and the same rules of precedence in heat blocking apply here as Arizona. It's mostly about blocking radiation, not about insulating... I installed a sub-rafter radiant barrier beneath the roof of my garage, two years ago, with dramatic results towards keeping my garage cool. There is also ventilation...

So Matt's ideas about air flow are surely important. My only question might be "Can we get MORE air flow?" I see no numbers here, only ideas.

Huh. I grew up in a stucco house. Never had a single problem with the stucco or anything behind it. I seriously doubt that they used anything like this behind the stucco. The house was old enough that the interior walls were plaster on lath. The house leaked air like a sieve I'm sure, and I don't think they bothered with any wall insulation, but there was never any problem with the walls not drying out. The floor under the laundry equipment rotted out, but the walls were always in good shape.

Old homes were constructed with vastly different materials and techniques. Old homes were energy hogs but they were great at ventilating and drying. Today we try to build tight envelopes with materials like OSB that don't tolerate moisture well. In short, the tighter envelopes and manufactured material used to in today's construction significantly increase the need for installation methods and materials that allow the home to dry.

The text on this product is...upside down in the install. And as they're demonstrating the product. Why?

Question: what is the lifespan of the synthetic material?

Why you guys still using Stuco nail??? In California we use. Staples.

Can I use Staples for it??

3:38 I think you mean "dimples"

Nope, the raised side "nipples" is facing the house. The dimples are facing the outside.

Moderators missed a subtle benefit of non-metallic stucco substrate. It's transparent to radio waves! Chicken wire, on the contrary, blocks wi-fi, and especially 433 mhz (70cm wavelength) signals commonly associated with home gadgetry like driveway sensors, and even wireless smoke alarms. (Yes, that might matter.) I rely on doorways and windows for penetration by desired radio signals, and that's a headache. So non-metallic is a welcome building science improvement, here. By the way, I'm changing all the smoke alarms in my house to wireless DSC NEO, and they operate at roughly 900 mhz. I will get a "condolence e-mail" if my house catches fire when I'm not home ;)

Great point John! Hadn’t thought of that

@@buildshow Radiation is one of my obsessions ;)

With these dimple mats you put behind walls all the time, especially the ones below grade, I have to wonder how those are going to last over time. Is that plastic going to break down and fall apart after 25 years?

Stucco has always gad an air gap behind it on properly done jobs.

It was called the "paper" but it was like tar paper that has several loose layers.

This new stuff should do a good job but may make repairs harder than when "paper" is used.

2 layers of tar paper works since it leaves a little gap, but a lot of cheap builders only use 1 layer or staple lath right over tyvek. Those homeowners are in for a surprise down the road.

@@bigpjohnson Saving pennies now that cost the customer big bucks later . . . I can think of another word for such builders rather than just cheap :-0)

A great video that I would never show a client. The title and thumbnail are the digital equivalent of vinyl siding.

I wouldn’t share this, but I always click the ‘like’ button.

where can i get a good polyurea clear coat @Matt Risinger ? I've got some floors and doors to make shiny.

Why not use waterproof stucco?

@Marc T You shouldn't let concrete, which is pourous, get wet. Salts will be lifted and create unsightly stains on surfaces. This is called "efflorescence." As in "flowering" ... of salt from within the concrete. Not good! www.thebalance.com/definition-of-efflorescence-1798544

Your stucco applicators in the background don't have a mud stand for them? The manufacturer who makes your scaffolding also makes mud stands, that way your applicators don't have to bend over all the time.

Hope anyone can answer this for me. I am thinking about using Tyvek to wrap the house and before using the Delta Dry Lath system, do I need to put another layer on the black paper on top of the Tyvek? Also, can the Delta Dry Lath system be used with both Stone Veneer and Stucco or do I need to go with the Delta Stone and Stucco system?

Any ideas if this would be a good product for an icf house?

ICF folks say so, but I'd like to hear Matt's take on that, too.

ICF is pretty cheap and lacking most of the time...

Does anyone know where you can buy Dorken Delta Dry & Lath? I went on Dorken’s website, but there’s nothing. Says some products are available at Lowe’s but when I called them they could not source either. Help!

Is "stucco" a plaster based fassade material? There are products available that have a binder in it preventing all capillary forces (this has been standard for a long time where I life). Those plaster based fassades are completely water resistant for life (and can go on on either brick/concrete and similar or also on other stuff like synthetic insulation).

So either "stucco" is a different kind of thing and not plaster based (but it looks like it is), but the statement that plaster based fassades soak water like crazy is just not true when you use the right product. (also the addition of net structures is mandatory in all plaster based fassades in my home country, the net structure application shown here around the windows and doors would not be to code here. The net structure in the plaster here would not resist the forces well if it isn't double netted with 45° at the corners).

I think the word you're looking for is "facade."

Acrylic stucco is waterproof , so i am assuming that we don't need the delta product behind it.

How about the intersections, Windows, electric boxes, etc. won’t that caulk crack eventually and get water behind it? Then it’s probably worse that it’s waterproof as it can’t dry through it

@@buildshow At least in central europe where I life those plasters (waterproof after drying) have been used for a very long time successfully. There are code regulations on how to install windows (basically all intersections) properly so they last a lifetime, but you need products that are designed to work together (I don't think you can just take any american window frame and use it as it is, as those have to have certain overlaps to allow the correct adhesion of the product). Additionally all those fassades are netted (like the polyester net shown in the video), doubly at the windows (in 45° offset). The plaster itself will not crack (they are quite flexible after drying, there usually is a lot of acrylic binder in them, if they are of good quality).

But I wouldn't just mix window frames and methods for applying the plaster that come from a different mindset with those acrylic bound plasters without going through all the details to make sure it works in the end (as I said, these are meant to be used in a system provided from one manufacturer, or designed to work properly together to specific norms by multiple companies).

What is a WRB would you recommend for brick?

For brick, tar paper over sheathing works fine. ZIP works well too.

Brick is always installed with a 1-2" air gap, so its naturally venting and drying out on its own. Dimple mat would work, but its overkill.

Question: Why don't you paint the stucco to make it non-porous?

I own a stucco house in Long Beach California. It's painted and the paint fades. The purists around here have their stucco houses sandblasted and re-stuccoed. A PhD structural engineer (retired) across the street from me did this and his house is the most beautiful on the block. So was my father's house, when he built his stucco house in 1957, in Glendale, where I grew up. Paint is a downgrade, and I'm thinking of sandblasting...

The engineer's two-story house across the street has a huge wall with southerly exposure, of which I have a direct view. The rainfall in Long Beach, and especially where I live, typically blows from the south, and that big wall gets visibly soaked. It's very impressive to see how wet that wall gets in contrast to the upper region which stays dry by virtue of the roof's eave. Within a few hours of rainfall cessation, that wall dries out, every time, and the wall is again uniform in color instead of light in the dry and dark in the wet.

@@johnbecich9540 I grew up in Southern California and lived in a stucco house. Never noticed (as a kid) that the stucco showed a "wetness" after a rain. I suppose it did, just never noticed. Anyway, perhaps paint does fade, but better that than algae due to retained moisture. So, what about a clear coat? Wouldn't that give the waterproofing while still retaining original color?

Painted stucco isn’t really waterproof. It still absorbs water but can’t dry as easily. When the sun hits this wall the solar drive causes that moisture to move towards the house which leads to bad things.

Better question: Why not use a product with a binder that prohibits all capillary forces and makes the fassade water-resistant? ;)

I wouldn't paint it though, usually just painting is not a good way to seal anything.

Hey Matt I only Stucco on brick you think this product would be just a good or better?

You could eliminate the brick!

Similar performance. Well done on the stucco over brick

Great I’ll look into it some more but I really think peal and stick would be better behind it rather than the zip board I would feel better about it sealing up the nails I can’t get to after the product is on....

nice Video but why do you install a Water/Air tight ZIP 2.0 system and than throw this Delta product onto the wall and nail the crap out of it??? Those nails sooner or later will fail and leave open holes in the wall. Why can't you take ZIP 2.0 system a step further and use a caulk as adhesive to apply the Delta system to the wall before you stucco so you don't have nails penetration your ZIP 2.0 system??? So far all the systems I have seen will not last for ever most what I see on the build show only will last less than 50 years before it require a major rework.

This product is a disaster just waiting to happen. The reason 30 lb felt, or even 15 lb felt works is because of the seal created around penetrations by way the oil in the felt. On the surface this product looks like it's plastic, which is not self-healing at all. But that's not the biggest problem, the biggest problem is whatever you have a product like this they tend to work perfectly on flat two-dimensional surfaces. But as soon as you get into the real three-dimensional world installers don't know how to apply their traditional techniques to the oddity of new products. While you can reasonably blame the installer, his fault is more in the choice of the material relative to his skill than in the skillet self. Products like these tend to speed things up, put more money in the hands of manufacturers, and deprive the end-user of the peace of mind and value created by of the time-tested techniques that built the trades in the first place.

Why not one person holding spraying gun. Other person smooth it

But now you are putting nail holes in your zip wall wheres water will follow the nail/staples right to the inside.

I was thinking the same thing?

No. They penetrate the zip but have an air gap in front of them which means there is no pressure to force in water AND it means the cavity will drain & dry!

Ok . But I’d rather not have the holes

Quit Dorken around Matt!

Based on your video, this delta dry and lath product is rated or tested as a Grade D building paper equivalent??or is the zip system rated equivalent to two layers of Grade D paper. The old stucco installers preferred the building paper because it absorbed all of the moisture from the initial install and when it dried it formed creases and wrinkles creating a bit of an air gap/drainage plan. It seems like a really antiquated method given the technological advances, but curious which product in your video is providing the two layers of WRB required by code?

The Zip is the WRB (initial layer of tar paper equivalent but better) The Delta Dry and Lath forms the air gap like the crinkle layer of the second layer of tar paper (but much better). This assembly meets code in every region of the US and Canada to my knowledge.

Is stucco still a thing? I thought it died in the 80's allong with bowling alleys in the basement.

I don’t even want stucco.

Call me crazy but you take all the time to tape the joints and screws installing the zip then they go and punch a bunch of holes installing the drip backer, doesn't make sense to me. Now I'm wondering about any siding installation, everything seems like it defeats the purpose of the zip siding???

It addresses it by leaving an air gap! That gap is critical to drainage and drying. Thus the holes don’t leak. No air pressure to force it in. Drying occurs with out incident of rot.

@@buildshow We're talking about two different things, lol. I get the whole air gap behind the stucco. I was just referring to the instances of cavity penetration that occur on every job.

How do you say this is better then traditional methods when it’s not proven. It’s like saying that pex will out last copper or kerdi is better then a hot mop. Only time will tell. All I know is that traditional methods are proven.

Sensors, and analytical equipment can be installed in a test structure. Moisture, heat, even bug infesetations can be measured, and compared to traditional structures.

Great videos usually but this one doesn't seem to address the elephant in the room. "How does it seal those thousands of holes in your ZIP surface you're creating by stapling it?"

It addresses it by leaving an air gap! That gap is critical to drainage and drying. Thus the holes don’t leak. No air pressure to force it in. Drying occurs with out incident of rot.

@@buildshow Maybe I'm just overcautious but wind could create pressure and drive that moisture into zip system. Isn't that what was simulated on your video "tyvek vs zip" by Zip guys? I'm just not sure how much pressure wind would create. Don't take me wrong I'm a big fan of what you're doing, just a small detail I've noticed. :-)

Alright man, I've done everything except call them up, where can a guy buy Delta stuff?

Might need to call them for your local supplier or they can sell to you directly. Its stocked in Austin at All-Tex Supply

Hi Adam, please email pbarrett@dorken.com for assistance locating products near you.

Why do people around here in KC paint stucco? Completely stupid.

Stucco is a NOGO. I will NEVER have a house with that crap on it.

You are a funny one. Good luck.

Why not?

@@942687032679840126 Look at 7:30 on the video.

@@zeake13 imagine if I showed a picture of a old car smashed into a wall and said that I will never ride any car because of that.

@@ryszardbargiel7256 imagine, I've worked construction and seen first hand how stucco is garbage. .... Bricks are the best in my experience. I could break through a stucco wall bare handed. You can't do that with bricks.

Shame on you for the L shaped panels

Hope Luke's using 100% vegan, organic stucco or the homeowner might be allergic to it.

I am not reading the all the comments...but you spend all the time taping and spotting the fasteners on the Zip" but than come along and nail and staple this product all over the the Zip ?

Efis foam system is always the best bet for the zip system. Basecoat mud is applied and grooved on one side of the foam, then applied over the zip system like tile over baseboard.

The insulation factor in much better and repairs like magic 👍🏻

This is a gimmick and you want it under your stucco because it will make me money so buy it up suckers .

Korean language plz....

Use your laptop and download as add on Google translate and it will do a live translatation