Velocity Stacks - What they do and how to make them... a.k.a. Air horns, ram pipes, air trumpets....

Vložit

- čas přidán 1. 06. 2024

- I need to make some new velocity stacks for my individual throttle bodies as I had to break the last ones....

I walk through each step I take to research, design and manufacture some velocity stacks for my motorcycle individual throttle bodies....

If you'd like to support the channel please check out the Patreon...

/ makingformotorsport

00:00 Introduction

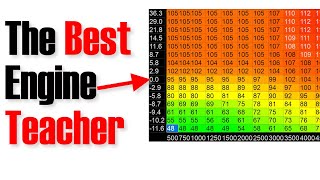

01:09 What do they do?

03:12 What is pule tuning?

05:02 Taper or Parallel

06:28 Design and Making

09:13 Fitting and Testing

11:30 Summary

Link to the research paper shown in the video...

www.researchgate.net/publicat...

Link a great piece of practical testing by the legendary Dave Walker of Emerald showing maybe taper isn't all that....

www.emeraldm3d.com/articles/e... - Auta a dopravní prostředky

Hell Yeah no more… the Modelling is here!!!

czcams.com/video/YBt7YM9BCHA/video.html

Actually… still give a Hell Yeah!!!

Hell Yeah!!!

Hell yeah - more modelling

Cheers buddy! Looks like my next video is decided!

@@MakingforMotorsport Looking forward to that

O yes! More modelling please

For those wondering, "Garage 4age" made more than 100 runs on his dyno from standard pipes to 600mm pipes.

Saw they make to 1m!

Hell yeah - more modelling.

3d printing kicking goals again. Love it

Cheers bud… it’s just perfect for stuff like this!

HELL YEAH MORE MODELLING

2:00 this little fact gave me an idea for a simple variable intake system that I haven't been able to test even after all these years. If the sharp inlet effectively narrows the inlet cross section, then it makes sense that you could use this effect to tune the physical runners to act like narrower and proportionally longer runners for lower rpm torque bias.

Mechanically I'm thinking either a sleeve that can slide above the trumpet to disrupt the flow, or slide down exposing ports below the trumpet that allow some aor to bypass the main inlet.

A much simpler mechanism might be a solenoid powered valve that allows air to enter the runner below the inlet, thus disrupting the flow and effectively reducing the runner cross section.

I think 3d printing is a brilliant way to go . I've just spent countess hours making molds to construct fibreglass/ epoxy velocity stacks , I still have to fit mounting bracket . You can make yours in your sleep.

That is, hands down, the best bit about 3D printing… unless of course it’s a failed print… in which case I want to set fire to the world! 😂

@@MakingforMotorsport Bambu Lab X1C Printer. Never ever worry about that again. Thing thing is bomb proof!!

@@toast47624 got one! Need to get it setup!

Hell yes, more modeling and more science. Love this stuff.

More modelling and more science… 2 things I can definitely do 👍

Hell yeah more modeling ! thanks for sharing your knowledgde

Hell yeah! 👍

Good tutorial. One major thing missing though. For carburettors and single runner (especially parallel) tracts, you can't just make the trumpet as long as you would like. The fuel spray tube must be situated anywhere in the 'first third' distance of the inlet tract, as measured from the air entry end. If the spray tube is positioned half (way) to three quarters down the tract, it will then reside in a higher pressure region, severely affecting the amount of fuel being drawn off the spray tube/main jet. This badly affects acceleration carburetion and can at the very least manifest as a flat-spot which takes some time to accelerate through, and at worst, a massive flat-spot situation which the engine just can't pass through, hence severely limiting the rev capability of the engine. Fuel injected engines don't suffer any of these negative effects. All these effects are easy to test/simulate using an engine dynamometer equipped with some very basic test equipment. experto crede.

Fair enough… I can’t claim to know anything about the dark arts of carburation so this is great knowledge!

Tre Bushett, what would define the entire inlet tract? If one end is the air entry end is the other the intake valve itself? I ask as someone who runs a single carburetor and is looking at adding a velocity stack. The intake manifold after the carburetor is quite long though.

Hell yeah. More modeling.

Hell yeah. Video going into a alternate explanation of pulse wave tuning.

We're not here for videos that don't explain things. There's a billion of those on CZcams. LOL

😂😂😂 you got me! It’s fairly similar but I want to be 100% if I do properly explain something… nothing worse than being picked apart on the comments forevermore!!!

@@MakingforMotorsport "well I just watched this video you made nine years ago and I wanted to comment about how you were completely wrong because you left out this one particular part about it." -- roughly what some guy left me the other day...

I completely understand.

Love that! How constructive!

Thanks for that flow analysis highlight. Seems like an interesting service!

You keep doing the projects I've been meaning to do for years and I love it!

Ha! These are the projects I have been meaning to do for years aswell! Thanks for watching glad you’ve enjoyed it!

No, no, please, no more modelling!

Great video. Best explanation of velocity stacks I've ever seen.

Haha! Sorry Josh but your in the minority here… you may need to sit the modelling video out 😂🙈👍

Hell yeah - more modelling :-) I've been running a short 3D printed single ram pipe on my mini (single HIF44) for years. I'm not sure if it helps either but it looks the part :-)

I am not gonna lie, looking cool is like 90% of the battle… 😂

Hell yeah - more modelling.

Your style and content are really spot on, keep up the great work.

Cheers bud, “more modelling” next video to land 👍

Your videos are literally amongst the most interesting videos i have seen on youtube!

Cheers buddy, that means a lot! More coming soon 👍

You're onto a winner with content like this! The mix of science and fabrication, plus it's for automotive use, is great and also helpful for my projects.👍

Cheers bud, it's just the stuff that would interest me... glad you like it!

Mad rally cross skills mate, cheers!

3d printing is great for small scale motorsports projects, I use the sovol sv01, which is fairly similar in design to the ender. great vids, thanks

Great job mate. Awesome build

Cheers buddy! 👍

Hell yeah, more modelling. I'm currently learning 3d CAD and 3d printing to make a new inlet manifold for ITBs on my MX5 hillclimber currently running CBR600 ITBs on a home fabricated aluminium manifold but I'm building a bigger bore motor with a VVT head, cams, forged pistons etc and have a set of ZX10R bodies to go on it. I'd love to see the development of your manifold in CAD too.

You sound like a man after my own heart! When I do the modelling video I will tie it up with the manifold… they both use different but very useful techniques so I will do the together… 👍. Best of luck with the build!

@@MakingforMotorsport Cheers Bud, been mucking about with motors all my life (light vehicle mechanic C&G qualified early 80s). The car is running well at the moment, 1839cc std bottom end with a lightly worked head, 285 Piper cams and the CBR 600 ITBs and a custom (Ok home made :-) ) exhaust making 160BHP currently (flywheel) on Emerald K3 management.

This is such a nice and beautiful and informative video! Love your vids, subbed!

Thanks bud… plenty more coming! 👍

Wow, this channel is absolute treasure! Just needed to understand velocity stacks, as i wanted to 3D print some for my carb, turns out he also made his own and covered how and wich fillament, so mutch more than i expected and now see he also cover 3D scanning and aerodynamics, which i have wondered about a lot since it would be usefull for printing front bumpers and grills.

Absolute god like content!

Cheers bud! Glad you’re enjoying it! Plenty more to come!

This vid is gold! I actually struggled with my motorcycle cafe racer conversion air filter placement and thanks to you and your episode about carbon nylon filament I am currently building my intakes in F360! Looking forward to more of this stuff. My next project gets an EFI conversion as well! Speeduino & NO2C FTW :) Cheers, mate!

Cheers bud, I am glad it all helps and comments like this make it ALL worthwhile 👍.

Stick around as there is plenty coming on ECUs and tuning!

Very cool video. There is so much to unpack in this topic so ill look for your vid on that.

One thing you might consider trying is putting a blade at the bell mouth area. I use them on itbs and carbs and they help point the flow in the right direction.

Another thing to consider for those doing this in a plenum. Make sure they extend into the air volume. Air sticks to walls and you get better flow if you roll the lip around and its away from walls.

Hell yeah - more modeling!

He encontrado una mina de oro, justamente lo que buscaba y aparecio en recomendados, me encanta el diseño y mucho más si tiene que ver con piezas automotrices!! I LOVE THIS CHANNEL

I am afraid my Spanish is fairly limited to specific utility phrases but I think I get the idea of what you are saying so I shall simply reply - “Dos Cervesa por favor!”

awesome! looking forward to the theoretical stuff!

I am looking forward to filming it… 👍

I'm blown away by the engineering here, but the driving oh my..

I aim to please… glad you enjoyed it!

Another wonderful video

Cheers buddy… a bit overdue this one but I enjoyed it!

great video mate, keep it up!

Cheers bud!

Very cool to see R&D backing up a home made design

I saw this software and know I had to have a go at it....

This video is excellent!!

Cheers bud! 👍

My kind of science.... subscribed!!!

Cheers bud 👍

Love the 3D printing aspects of your builds and the fact that 2 Stroke Stuffings is also 3D printing inlets because of your videos. And He’ll Yeah to modeling content. In the the throws of putting together a half decent cnc router and need to learn this for that. Keep the videos coming

Cheers buddy! I love Alex’s videos, very smart fella (although he had his printer well before I said anything to about CF-Nylon to him)!

Very jealous of you doing the CNC stuff… that’s something I’d love… is it a lot or fully bespoke?

@@MakingforMotorsport It’s a scratch build, fully welded steel construction for the frame and gantry, 16mm steel plate bed. It’s a router but built to cut alloy and steel mainly. BUT….. it was meant to be a quick 6 month build and that was 2 1/2 years ago and I reckon I’m about half done lol. Life just keeps jumping in the way lol. Anyway. Love the vids, great content, easy watching style, well edited. Keep it up 👍

You drive like an absolute maniac, I love it!

that's what my Wife says! Cheers Bud!

Very interested In a separate video talking about intake pulsing, the “supercharger effect” and more flow testing

Absolutely! I really enjoyed putting together the pieces for this video so you can guarantee there will be more coming!

Great video!

Cheers bud, glad you enjoyed it 👍

Hell yeah more modelling

Love your work

👍👍 thanks mate, “more modelling” is the next video out…. Watch this space 👀

Great content! I am starting out on a new TVR Cerbera induction/ITB's project to get the horsepower and more importantly, pulse tuning working well on TVR's own AJP8 (in-house V8 engine). You may know there are two key AJP8 variations, a 4.2L and a 4.5L and each variation has its own special and bespoke induction system. I have decided to build a new induction system that follows the problem solving methods that Yamaha followed to gain an extra 80HP from the standard Ford Taurus V6 engine. The Taurus was sent to Yamaha to get the engine performance increased, which they did in part by building an intake indicator system with two runners per head inlet! You were going to film a highly detailed explanation of pulse tuning and the "supercharging" effect, I have looked but I can't find this. If you have any outside links that may help me in my quest I would be very grateful. Please keep going, you have my support! Kind Regards Neil

Good video. I like cars. I like 3d printing. I like modeling. Was going to make my own velocity stacks, too. Good to know about ASA as I've just started printing with it and I'm liking it

Great info here

nice to see another vauxhall 8v on bike bodies! not that anyone ever wants my 2p but you'll get it anyway.

- a tapered tube flows better than a parallel tube.

- you'll need your inlet way longer for pulse tuning.

- the biggest improvement you could have made for power is get rid of the air filter and keep the original velocity stacks

- if you want a filter make an air box with cold air feed any loss of flow through a filter will be gained by denser air.

- you wont have enough room under the bonnet for both pulse tuning and an air box and the cold air would be more beneficial than any pulse tuning.

- make them twice as long with a1.5deg taper and poking out trough the bonnet with an air box/scoop out the top of the bonnet and no filter.

You make some good points, but like I said in the video, in my level of application all the evidence I have found is people not finding a different between taper and parallel (maybe on a full race engine with a taper all the way to the back of the valve - but I am not there), the bell on the stack was far more important to me…

After having my engine swallow a small stone (very open engine bay) I will always run filters - they may not help power but neither does running on 3! 😂

I ran the numbers on pulse tuning for 3k rpm and just gave up trying to fit it in, do-able but worth the effort? I doubt it…

More cold air helps definitely, but I rarely see IATs much more than 5deg over ambient ‘cus it’s a space frame front end, plus packaging constraints mean it’s gonna be difficult to fit a plenum and ducting to give cold air….

On a more “normal” road car I’d agree with, and implement most of them, but this project has some challenges 👍😂

Another great video thanks! Going to check out that CFD program, didnt know that was available outside of a really exspensive cad system!

I found it from another CZcamsr but it’s great, and you can do thermodynamic and FEA work and others… it’s a piece of kit considering it’s FREEEEEEE!!!

Hell yeah-more modelling please, love the vids

That’s what I was hoping for 👍

Hell yeah, more modeling!!

👍

I absolutely love it. 3D modeling and optimizing of intake parts is a really low cost tuning factor. I always wonder why there are not more people doing it. Some time ago I designed an intake out of TPU with internal helical flaps for my carbureted bike and it massively improved the throttle response especially in mid range.

My bike buddy, who is obsessed with everything being stock, shiny and perfect, was shocked when I told him I installed a 3D printed part on my engine😂. He was trying to convince me it's unsafe. But I just laughed because he has no clue how strong TPU actually is...

There’s a lot of mistrust around 3D printed parts and whilst FDM and PLA isn’t good for everything but you can still do alot with good filament and clever design 👍. I like the sound of these helical flaps! How did they work?

Equally interested.

The TPU intake sits in between the carb and the airbox. Since its a 620cc 4 valve single cylinder engine with low rotational mass, it is very responsive to small changes in AFR.

Now my plan was to get the intake air to rotate around its direction of travel before it passes the carburetor, to unify and improve the mixture. There are three helical flaps with variable pitch inside, connected in the center. They start with a low pitch (almost parallel to the direction of travel) at the airbox and 80mm down right infront of the carb they are at an angle of around 25 degress in relation to the flow direction.

@@them0leisback wow, so you were introducing a “spiral” in the air as it went down the runner to introduce controlled “turbulence” to keep the mixture homogenous? I like the sound of it…. As you say, a small engine will show up any differences quickly so it was a obviously an improvement…

If I am getting it right, these are static? Like not an actively controlled part?

I'm doing similar things as you with my printer. I also have a CNC mill. I use both. Recently brought a Bambu Lab CX1 and I can't recommend it highly enough. Its been 100% hassle free, just plug and play.

hell yeah more modeling!

Hell Yeah, more modelling, also you are awesome and I just subscribed

Thanks for the sub! Really glad you enjoyed it!

Hell yeah, more modeling

Hell yeah, more more modelling!

Hell yeah more modeling!

Absolutely 👍

Cool channel!

Dude you a great driver, like a stunt driver

Hell yeah! More modelling 💪

I have an "AFM delete piece" 3d printed in ASA (had it done on 3dhubs because i don't have a printer) that sits right behind the radiator on my miata and had no problems even in 30°C+ trackdays, someone i know even has PLA velocity stacks on his miata and they are still going strong after years in the heat of Sicily (30-40°C summers), i think you won't have any problems with yours!

Yeah, PLA I think could be marginal, a friend has had theirs melt slightly but I do love ASA, it works really well for most applications, and prints lovely…

Years ago there was a cheap and simple mod for the BMW R1100RT motorcycle and that was to fit the inlet trumpets from the R1100GS, these were much longer and were in fact velocity stacks. Net result of the change was noticeably more low end torque, just where you want it. Allegedly, you lost top end power, but that was of no consequence, so a good win and well worth the effort (so was a remap, but that's another story all together).

By the way, Porsche fitted engine controlled, adjustable length, velocity stack to some of its flat six engines, that’s got to be the best win

I heard a few bits about the Porsche system, and few other bits like dimples surface… it’s very interesting….

I'm just impressed you're using the ASA for the final product, not using it to test fit and then have the model sent off to a metal shop

ASA is proper material, and whilst I wouldn’t use it for applications for bolting to the engine, it’s great for everything else….

For applications bolting to the engines I use CF-Nylon 👍👍👍

Small correction in your video, its never a choice its ALWAYS Brittany. Cheers love the channel lots of cool ideas.

Oh man… Christina for me. I guess we’re enemies now… 🤷♂️

Im looking at doing a complete lower airbox for my motorcycle as my airbox is screwed but it has the verlosity stacks built in 👍, and demontweeks is just down the road from me lol it's definitely a wicked place to go 👍

in fact - if you don't mind making your own filters, ramair is not the cheapest.

also, if you're going to do a segment on inlet tract tuning, you could do another one for the equally important exhaust tuning. would love to see both.

Definitely do more modelling! I follow some CZcams channels that have 2nd channels for ‘insights’/behind the scenes/stuff they don’t want to clog the main channel with. My Mechanics is a great example of that.

2nd channel… hmmm I’d love to as it’d let me go into lots more detail but I struggle keeping up with 1!!! 😂🤯

@@MakingforMotorsport maybe a consideration for the future when you’re a full time content creator 😉

Haha! It may be a long wait for that to happen! It is a great compliment that you think that’d be possible! 👍

@@MakingforMotorsport well I shared the 3d printed tools video with a friend that builds rally cars for a living and he was amazed with the hole die and brake line straightener.

Think about how many amateur and hobbyist car builders there are out there, I think the audience is out there, they just need to find you!

Looking forward to the next video.

Hell-yeah!! More Modeling

Check out my last few videos…. Over 1.5hrs of 3D modelling in quite some detail! 👍

Hell yeah more modelling, lets get more onto it,

Absolutely…. 👍

Hell yeah! More modelling

Hell Yeah! More Modeling!

Hell Yeah!

Hell Yea, More Modeling

Hell Yeah, more modelling!

Great job!I also make ITBs for my motor and would like to watch a video with the calculation of the length of the trumpets.Have you ever thought about bringing trumpets into an airbox? A separate filter for each trumpet greatly reduces air consumption! In addition, the airbox allows you to supply cold air and install a factory filter! On the BMW M series, this is done from the factory .....)

Yeah, OEMs have lot of reasons for the airboxes…. on a lot of cars with ITBs as standard they tend to use Air Flow Meters for the fueling so they still need to route the air though… plus OEMs need a place to feedback block breather air etc to meet regs….

That said, it’s still much easier to route a cold feed to an air box rather than 4 ITBs!

@@MakingforMotorsport By the way ... on Toyota 4a-ge, the trumpets are bent, so that you can get the required intake length!)

@@MakingforMotorsport Your velocity stacks just beg to touch each other in a common plate. So you are almost there with your airbox. Also you could add 3% bend or angle to make the air box more compact. An airfilter is most effective with a constant flow of high density air. Thus the intake air goes straight to the airlifter (ram in orthogonal onto it -- a flat filter is best for this). Also a filter is basically a 2d sheet / net with pores which hold back particles which are too large for the clearances in the engine. You fold it until it fits into the engine bay. It is by no means a 3d foam where you need to be lucky that some particles stick on the oily surface. Just look up how the tubes in a particle filter are closed. On a cat the pores are small enough that the very hot and turbulent gas can carry the molecules via diffusion to the walls. A cat is not a filter.

Hell yeah more modeling

Hell yeah - more modelling

and by the way, nice format!!! I like the attempt to do more yourself instead just buy expensive stuff what at some level isnt better

Cheers bud! Making rather than buying is out of necessity but I just want to show people you can mess around with car without spending all the money! Maybe even have a bit more fun aswell 👍

Love this series of vids. Now I'm looking at TBs for my kit car, and I've not finished the first build yet! I noticed you were using a filler knife to remove the print, Having cut my hand more than once with that I've stopped using it. With the glass plate assuming it is a borosilicate plate pop it in the freezer with the print on and that will release it without needing a knife.

Yeah, good tip! since this video I have moved to a PEI flexplate which is EPIC!

Hell yeah more modeling 😝

Hell yeah - more modelling.

He'll yeah, more modeling, tutorials would be great also...

Check out a couple of the most recent videos… nearly 2 hrs of CAD on there 👍

Awsome 👌🏻😍

Cheers buddy👍

Great stuff!! Did you smooth the insides with acetone, or just use the surface off the print bed?

I just use the straight printed surfaces and just make sure that any blobs or stringing is sorted (minimal with the Asa) there will always be a boundary layer at the wall so as long as it’s relatively smooth as printed it’s fine…

He'll yeah! More modeling.......

When I do mine I'm going to try using the bigrep hi temp filament.

Heat resistant up to 160 degrees and only requires a nozzle temp of 215.

Bed temp of 60 with no surround so my CR10 should print this no problem.

I'm even planning on using it for my flange and manufold for ITBs so we'll see how well it holds up to the heat cycles.

I’ve seen this filament before, I must say the lack of information on the actual material was a concern, plus there was scant info the biodegradable bit, (how long? Under what conditions etc) but the stats do look good and bigrep are a decent brand…

Please, when you do try it let me know how it goes… I will be interested to see

@@MakingforMotorsport will do.

It will be a while however. Just test fitting with PLA at the moment until I get things running.

Think I'm on my fourth iteration of the manifold design. It's a tight space so every alteration is a compromise.

The car is a total rebuild so have hundreds of jobs to sort.

Hell yeah more modelling.

another great video, hell yeah. Question, can this stuff be done with ckeap entry level 3d printers or should I start with a bit up market one? (what features do I need?) Keep up the great work!

ps I used to run a rotary engined imp in autotests down here, downunder.

A rotary engined imp? Now that appeals in so many ways… love an imp…

Anyway, to answer your question, I am printing all this on my Ender3Pro (very cheap and entry level) which is slightly modified, there is more detail on my “3D printing Carbon Fibre Nylon on an Ender 3” video… although for the ASA I was using kapton tape on the bed.

I am also building an enclosure so I can start printing Polycarbonate… but even after the mods the cost will be half of something that can do it out the box…

The conanda effect makes air follw any curve so if you blow air on your table with hair dryer and it edge is rounded the air will flow down!

So on a V stack that curve grabs alot more air and smoothly !

HELL YEAH MORE MODELING!!

hell yeah just sub dope vid

Cheers buddy!

I think that 3D printing is very efficient for searching for the proper runner length 👍

You use taper to stabilize the airflow for the nozzles. You create a homogeneous hot spot for the nozzles where there are no differences in speed over the revrange used. That is, if you take a cross-section at right angles to the airflow above the main jet, there is little to no flow differences to be recognized over the entire revrange used. This makes tuning much more predictable and eliminates a variable. You do have this with a straight pipe because the wall always pulls on the airflow and makes the homogeneous cross section unpredictable.

Oh Salamander, you’re talking about the dark arts of carburettors…. Well beyond me I am afraid… I stick to the elec-trickery now!

Really incredible. i am blown away by how you broke the design down to it's simplest language.

However, I was under the impression that a hourglass shaped inlet was more ideal. Ie: flared inlet, choked center, flared outlet. It contributes to the venturi effect allowing increased airflow at slightly higher pressure. Am I wrong?

Thanks for the comments, glad you’re enjoying it!

In terms of inlet shape, what you are describing is the shape used in carbs where the constriction and Venturini effect gives the pressure difference to move the fuel, however in injection you don’t need this and the choke just acts as a constriction to flow. Yes, the air speeds up but as the diameter increases it slows down again. Obviously it’s far more complicated than this but generally the fewer restrictions the better 👍

Thanks for the reply. I suppose I wasn't thinking clearly

HELL YEAH MORE MODELLING! and 3d printing.

Coming soon buddy!

HELL YEA MORE MODELING PLZ

Hell yeah way more modeling

If you are interested there is about 2hrs of more modelling videos which I have recently done 👍

Very nice, I have an ender 3 also, could you share the settings you use for printing ASA?

New subscriber 🇦🇺🤜🏼🤛🏼🍀😎

Very cool... I’d be keen on some fusion 360 tutorials... just as long as they flow well.

Welcome along Steve, I have done a couple of Fusion vids, not necessarily tutorials as I am no tutor but just me talking…. Let me know if they flow well! 😂😬

hell yeah more modeling

Coming soon!

HELL YEAH - MORE MODELING! :D

Yes mate!! It has been done! Check out the pinned comment! 👍

@@MakingforMotorsport wicked!

Love this story of stuff and while I knew of ITBs and tuning their intake track, I can't believe that I totally was blind sided by pulse waves!

It's certainly given perspective to OEM air boxes and intake tracks as to why they are designed the way they are.

Science is a beautiful thing!

3d printing is fire

I am a big fan…. But not of fire…

Hell Yeah More Modelling

Why did you decide to use ASA for the velocity stacks when you'd already had success with the carbon reinforced nylon for the manifold? Is this purely down to the lesser heat and strength requirements? Or was it just cost based.

Being a cad designer myself I also have to say HELL YEAH MORE MODELING, it's nice to see other people's creative processes.

Keep it up, I love your videos, informative and entertaining.

Thanks for making me buy itbs… a 3D printer… and a cam… and an exhaust… for my 190e daily haha

Your welcome!! My pleasure to spread the passion/madness!!!